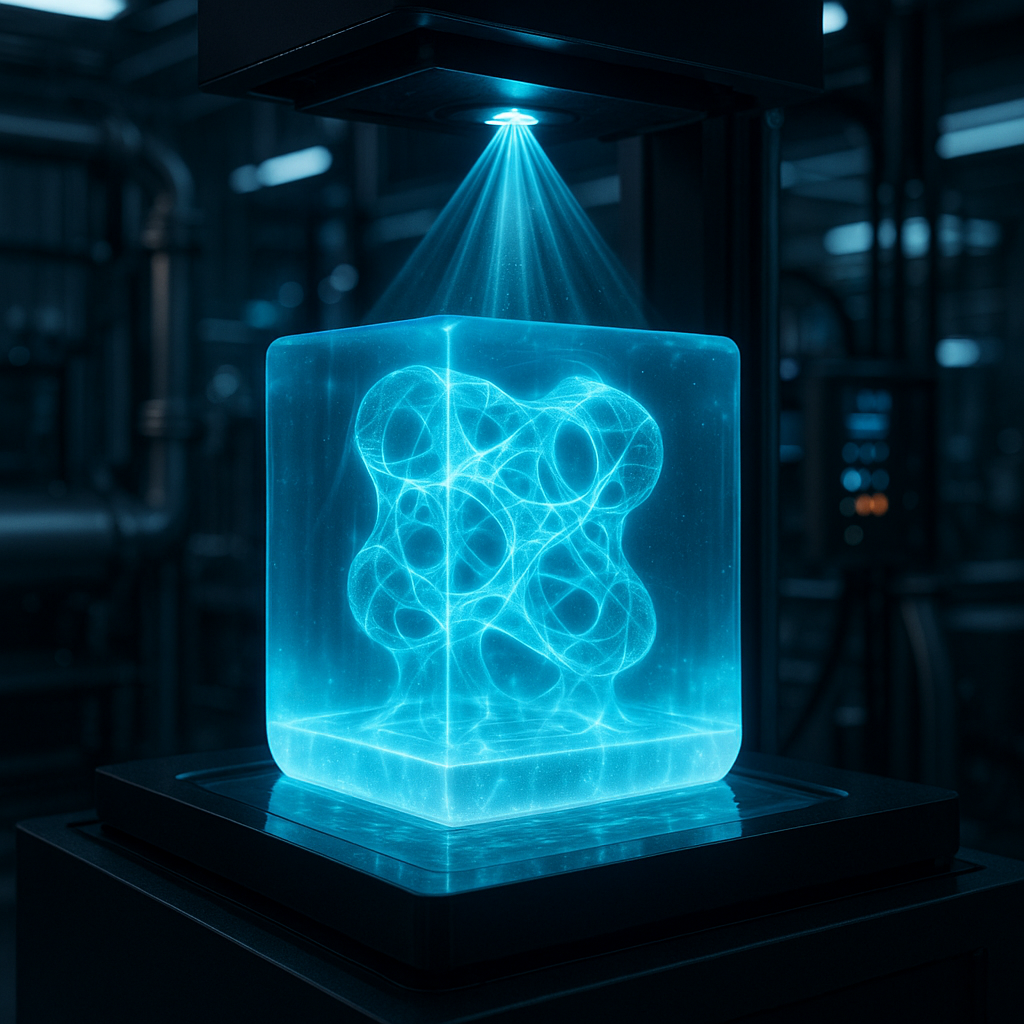

Recent developments spotlighted by courier-journal.com underscore volumetric 3D printing as a transformative force in global manufacturing. This innovative technology, which enables the creation of entire 3D objects in a single step by projecting light into a volume of photosensitive resin, is gaining traction among top 3D printing service suppliers aiming to drive efficiency and complexity in production.

What Happened

Leading 3D printing service providers have recently integrated volumetric 3D printing into their manufacturing portfolios, marking a pivotal shift from traditional layer-by-layer additive processes. These suppliers are leveraging volumetric printing’s rapid build speeds and ability to fabricate intricate geometries without support structures, thereby expanding the scope of manufacturable parts. While detailed deployment strategies remain undisclosed, the courier-journal.com report confirms these advances are already influencing manufacturing workflows globally.

Why It Matters

Volumetric 3D printing represents a significant departure from conventional additive manufacturing methods that build objects layer by layer. By curing entire volumes simultaneously, it drastically reduces production times from hours to minutes. This speed advantage, combined with the ability to fabricate complex internal structures without assembly or support removal, opens new possibilities in medical devices, aerospace components, and custom consumer products. Furthermore, faster throughput can lower costs and energy consumption, making manufacturing more sustainable. The technology’s adoption by top-tier service suppliers signals its readiness to impact industrial-scale production.

Technical Context

At its core, volumetric 3D printing utilizes computed axial lithography or similar volumetric photopolymerization techniques. A rotating volume of resin is exposed to dynamic light patterns that selectively solidify material in three dimensions simultaneously. Unlike stereolithography (SLA) or digital light processing (DLP), which cure one layer at a time, volumetric printing forms entire objects in a continuous exposure. This capability requires precise control of light modulation, resin chemistry tuned for rapid polymerization, and advanced computational algorithms to convert 3D models into volumetric light projections. Challenges remain in scaling build volumes, improving material diversity beyond photopolymers, and refining resolution to match traditional methods.

Near-term Prediction Model

In the next 12 to 24 months, volumetric 3D printing is expected to transition from pilot deployments to early commercial adoption within niche markets requiring rapid prototyping and complex geometries. Service providers will likely expand their volumetric printing capacity while continuing to refine process parameters and material offerings. Integration with existing additive manufacturing workflows will be critical to maximize utility. Broader industrial uptake may hinge on overcoming current limitations in material properties and build size. Nonetheless, the technology’s potential to reduce lead times and enable novel designs positions it as a disruptive innovation in manufacturing.

What to Watch

- Advancements in resin formulations that improve mechanical properties and expand functional applications.

- Development of larger-scale volumetric printers to accommodate bigger parts.

- Integration of volumetric printing with multi-material and hybrid manufacturing processes.

- Emerging standards and certification pathways for volumetric printed parts in regulated industries.

- Competitive responses from established additive manufacturing technologies and service providers.

While volumetric 3D printing is still maturing, its rapid progress and adoption by leading service suppliers, as reported by courier-journal.com, suggest it will be a critical technology to watch for anyone involved in advanced manufacturing innovation.