Volumetric 3D printing is emerging as a transformative technology in the additive manufacturing landscape, promising to revolutionize how objects are fabricated layer-free and at unprecedented speeds. According to a recent article from SNS Insider, global leaders in 3D printing are actively shaping the future of this technology, underscoring its potential impact across various industries.

What Happened

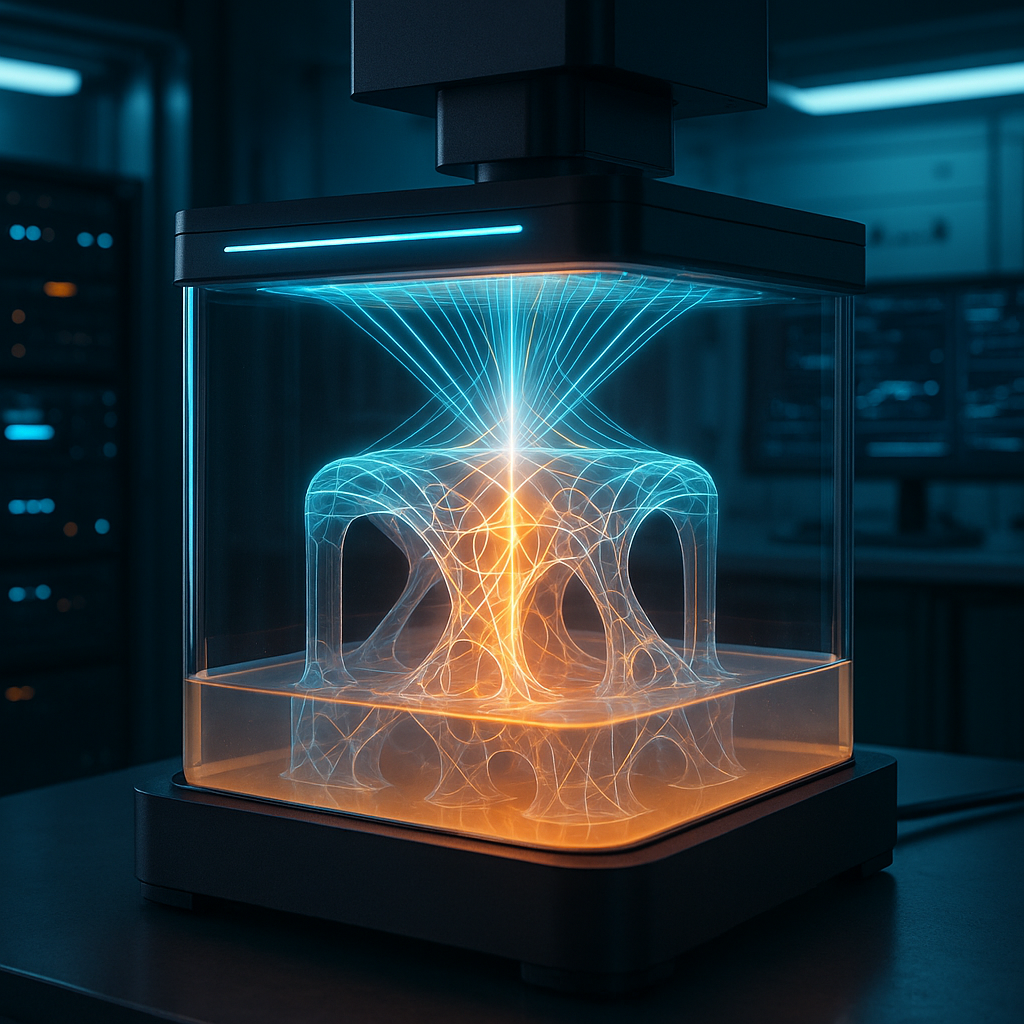

Volumetric 3D printing has gained increased attention as companies and research institutions demonstrate prototypes and pilot projects that leverage light-based volumetric techniques to create entire 3D objects in a single step. Unlike traditional layer-by-layer additive manufacturing, volumetric printing projects patterned light fields into a photosensitive resin volume, solidifying the object simultaneously throughout its volume. This advancement was highlighted in recent industry analyses, including the SNS Insider report, which identified key players and innovations pushing this technology toward commercial viability.

Why It Matters

The significance of volumetric 3D printing lies in its potential to drastically reduce print times from hours to minutes or even seconds, enabling rapid prototyping and production cycles. Moreover, the layerless nature of volumetric printing eliminates many mechanical weaknesses and anisotropies inherent in traditional layer-based prints, resulting in parts with superior mechanical properties and surface finishes. This could open new applications in medical devices, aerospace components, and complex fluidic systems where precision and material integrity are critical.

Technical Context

Volumetric 3D printing typically employs tomographic reconstruction principles, projecting multiple light patterns synchronized with the rotation of a resin-filled container. The resin polymerizes volumetrically where the cumulative light dose exceeds a threshold, forming the object simultaneously in three dimensions. This approach contrasts with conventional stereolithography or fused filament fabrication, which build objects incrementally. Current challenges include optimizing resin chemistries for rapid curing, improving resolution and accuracy, and scaling build volumes while maintaining uniform light exposure. Additionally, post-processing and support removal strategies differ significantly from conventional methods, requiring new workflows.

Near-term Prediction Model

In the next 12 to 24 months, volumetric 3D printing is expected to transition from pilot demonstrations to early commercial deployments in niche markets. Industries that demand rapid turnaround and complex geometries—such as dental, medical implants, and microfluidics—will likely lead adoption. Continued improvements in light source technology, resin formulations, and system integration will drive enhanced print quality and reliability. However, widespread industrial adoption will depend on overcoming scale limitations and establishing standardized materials and processes. The technology’s maturity is currently in the pilot phase, with commercial readiness anticipated within two years.

What to Watch

- Announcements of commercial volumetric 3D printers with scalable build volumes and improved resolution.

- Development of new photopolymer resins optimized for volumetric curing with tailored mechanical and biocompatible properties.

- Industry partnerships and collaborations aiming to integrate volumetric printing into existing manufacturing workflows.

- Regulatory approvals and certification processes for volumetrically printed medical and aerospace parts.

- Research breakthroughs addressing current limitations such as print accuracy, surface finish, and post-processing techniques.

In summary, volumetric 3D printing represents a promising frontier in additive manufacturing technology with the potential to redefine production speed and quality. While still in the pilot stage, its rapid evolution and growing interest from global leaders signal a paradigm shift that merits close attention from industry stakeholders and technologists alike.