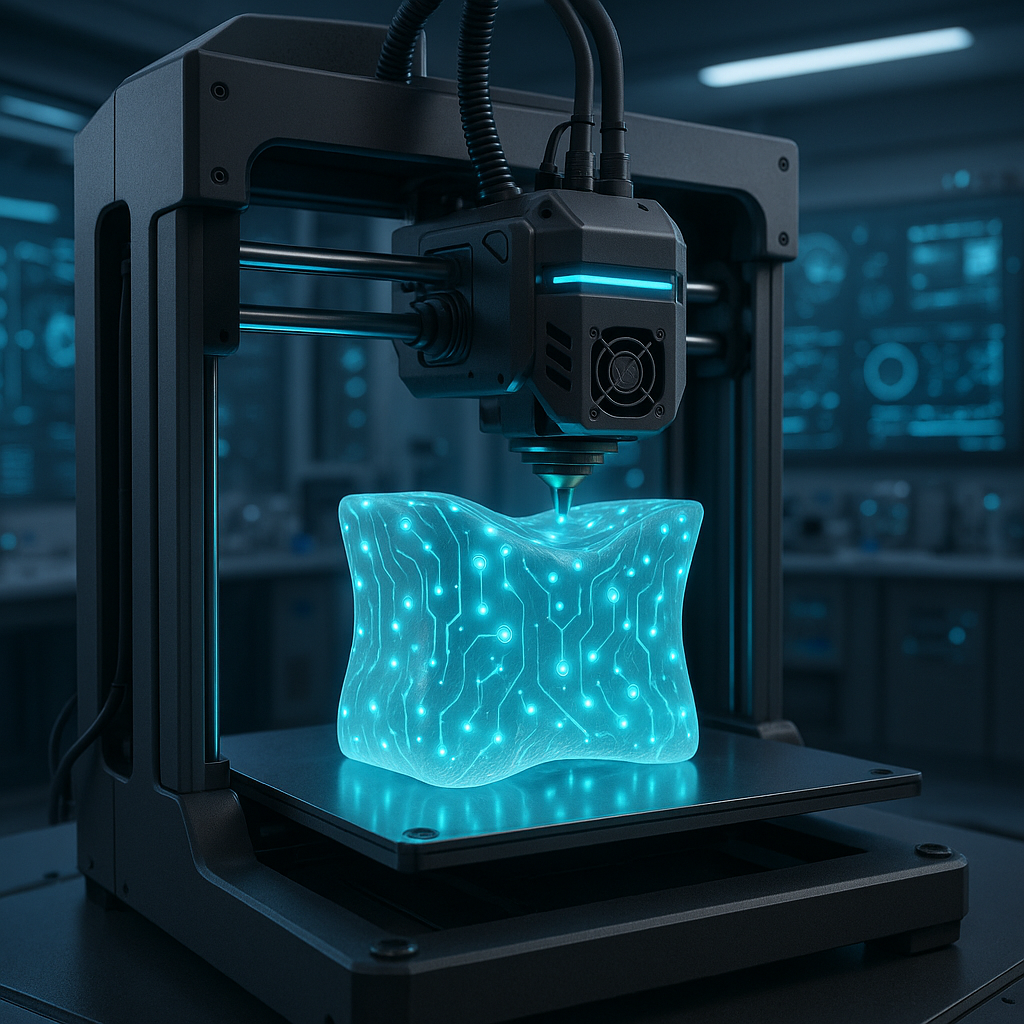

In a significant leap for additive manufacturing, Purdue University researchers have pioneered methods to add a ‘fourth dimension’ to traditional 3D printing by embedding sensors directly into printed materials. This advancement marks a critical step toward smart and bio-embedded materials that can sense, respond, and adapt to their environment.

What Happened

Purdue’s research team has developed a novel 3D printing approach that integrates embedded sensors within printed structures, effectively introducing a dynamic element—referred to as the ‘fourth dimension’—to static 3D printed objects. These embedded sensors enable the materials to monitor environmental changes or internal states, potentially leading to self-aware and adaptive printed components.

While the specific sensor types and printing materials used were not exhaustively detailed, the initiative focuses on combining traditional additive manufacturing with sensor technology to produce multifunctional materials that extend beyond shape and form.

Why It Matters

This development could revolutionize multiple industries by enabling the creation of smart materials that provide real-time data and adaptive capabilities. For example, in healthcare, bio-embedded sensors could monitor physiological conditions within implants or prosthetics, offering continuous health insights. In aerospace or automotive sectors, embedded sensors could track structural integrity or environmental stress, enhancing safety and maintenance efficiency.

Furthermore, embedding sensors during the printing process reduces the need for post-production assembly or retrofitting, streamlining manufacturing workflows and lowering costs. This integration paves the way for more complex, multifunctional devices with enhanced durability and performance.

Technical Context

Traditional 3D printing fabricates objects layer-by-layer, primarily focusing on static geometries and materials. The concept of 4D printing introduces time or responsiveness as an additional dimension, where printed objects can change shape or function in response to stimuli.

Purdue’s approach harnesses embedded sensors—likely micro-scale electronic components or responsive materials—integrated within the print layers. This requires precise control over print parameters and material compatibility to maintain sensor functionality and structural integrity.

Challenges in this domain include ensuring sensor durability during the printing process, maintaining connectivity and power supply to embedded components, and integrating sensor data transmission capabilities. The research from Purdue signals progress in overcoming these hurdles but leaves open questions about sensor types, data interfaces, and scalability.

Near-term Prediction Model

Given the current R&D status, Purdue’s embedded sensor 4D printing technology is expected to reach pilot-stage applications within 12 to 24 months. Early adopters may come from specialized sectors such as biomedical devices or aerospace components where smart materials provide distinct advantages.

Commercial scalability will depend on advances in compatible sensor materials, miniaturization, and integration with existing manufacturing systems. Within 3 to 5 years, this technology could become more widespread, influencing product designs that require embedded sensing and adaptive capabilities.

What to Watch

- Further technical disclosures from Purdue regarding sensor types, materials used, and integration methods.

- Demonstrations of functional prototypes showcasing real-world applications, especially in healthcare and industrial monitoring.

- Partnerships or collaborations between Purdue and industry leaders to transition from R&D to pilot production.

- Advancements in power solutions for embedded sensors, including wireless energy transfer or energy harvesting within printed materials.

- Regulatory and standardization efforts addressing embedded electronics in additive manufacturing.

As the field of smart and bio-embedded materials evolves, Purdue University’s contribution represents a pivotal step toward embedding intelligence directly into the fabric of 3D printed objects, unlocking new frontiers for responsive, adaptive, and multifunctional materials.