What Happened

The National Renewable Energy Laboratory (NREL) recently advanced research on the manufacturing and additive design of electric machines by 3D printing. This development integrates additive manufacturing techniques into the production of electric motors and generators, components critical for renewable energy technologies like wind turbines. By leveraging 3D printing, NREL aims to enable more flexible, localized, and efficient manufacturing processes that align with the principles of distributed manufacturing and digital inventory management.

Why It Matters

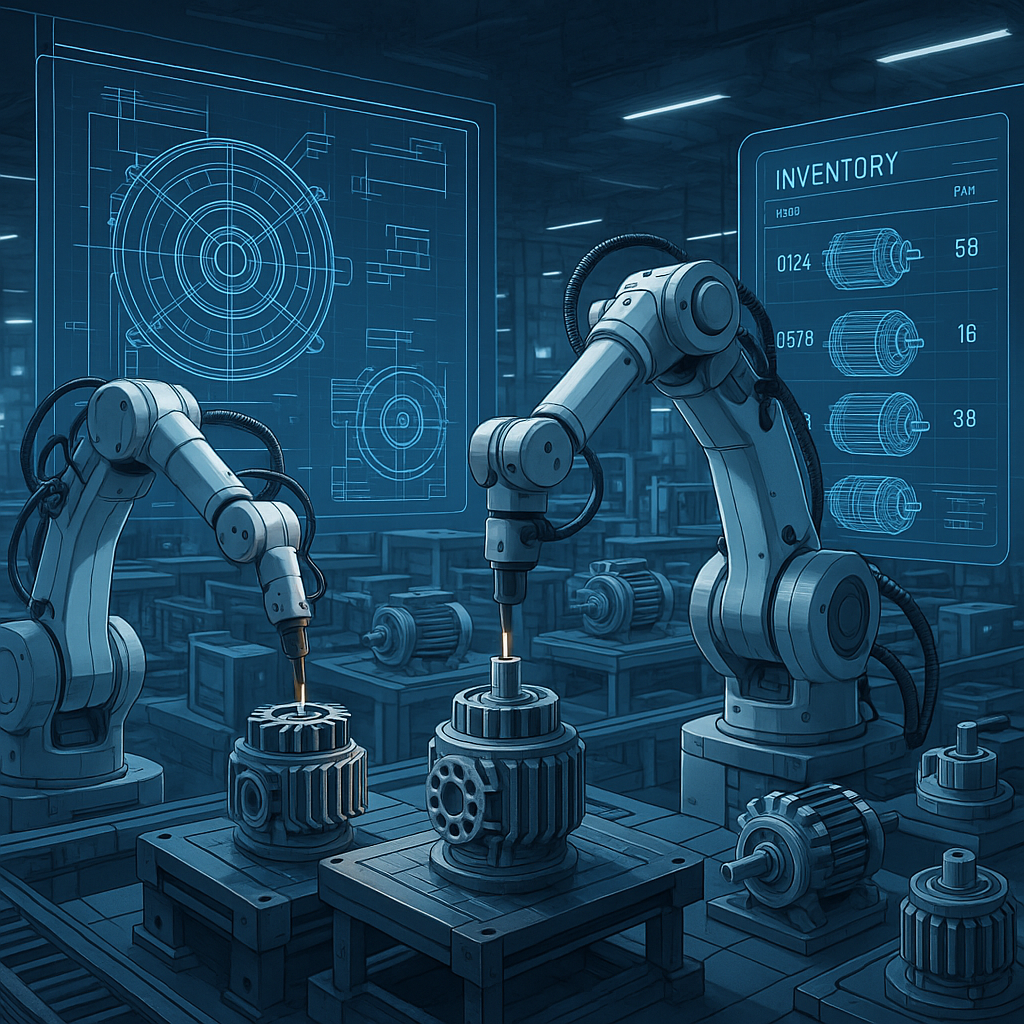

The integration of 3D printing in electric machine manufacturing signals a paradigm shift toward distributed manufacturing. Traditional supply chains for electric motors often rely on centralized factories with complex logistics and inventory management challenges. Transitioning to additive manufacturing allows components to be produced on-demand, closer to the point of use, reducing lead times, inventory costs, and transportation emissions.

This approach dovetails with the concept of digital inventory, where digital designs replace physical stockpiles, enabling rapid response to demand fluctuations and customization. For renewable energy systems, which require specialized parts that may not be mass-produced, this capability could significantly improve maintenance turnaround and system scalability.

Technical Context

Electric machines are complex assemblies involving precise magnetic, electrical, and mechanical components. Additive manufacturing introduces new design freedoms such as topology optimization, integrated cooling channels, and consolidated assembly, which are difficult or impossible with conventional manufacturing. NREL’s research focuses on adapting 3D printing materials and processes to meet the stringent performance and durability requirements of electric machines.

Key technical challenges include ensuring the magnetic properties of 3D printed materials meet or exceed those of traditional laminations, achieving mechanical robustness under operational stresses, and integrating conductive paths with minimal resistance. While some details about the specific materials and printer types used by NREL remain undisclosed, the research likely explores metal additive manufacturing techniques such as selective laser melting or binder jetting combined with post-processing treatments.

Near-Term Prediction Model

Within the next 12 to 24 months, pilot projects and prototypes of 3D printed electric machines will likely emerge in controlled industrial or research environments. These pilots will focus on demonstrating reliability, performance parity with traditional machines, and cost-effectiveness at small production scales. Initial applications may appear in niche renewable energy installations or specialized industrial equipment requiring rapid customization.

Wider commercial adoption will depend on overcoming current material and process limitations, scaling production speed, and establishing standards for qualification and certification. However, the trajectory suggests that by 2027, distributed manufacturing of electric machines via 3D printing could transition from pilot to early commercial stages, especially in sectors prioritizing supply chain resilience and sustainability.

What to Watch

- Material innovations enhancing magnetic and mechanical properties of 3D printed components.

- Development of hybrid manufacturing processes combining additive and subtractive methods for precision.

- Case studies demonstrating cost and time savings in maintenance and replacement of electric machines.

- Regulatory and certification frameworks adapting to additive manufacturing of critical electric components.

- Collaborations between renewable energy firms and additive manufacturing specialists to integrate digital inventory strategies.

Overall, NREL’s work exemplifies the emerging frontier where 3D printing intersects with distributed manufacturing and digital inventory, promising transformative impacts on how electric machines are designed, produced, and deployed.