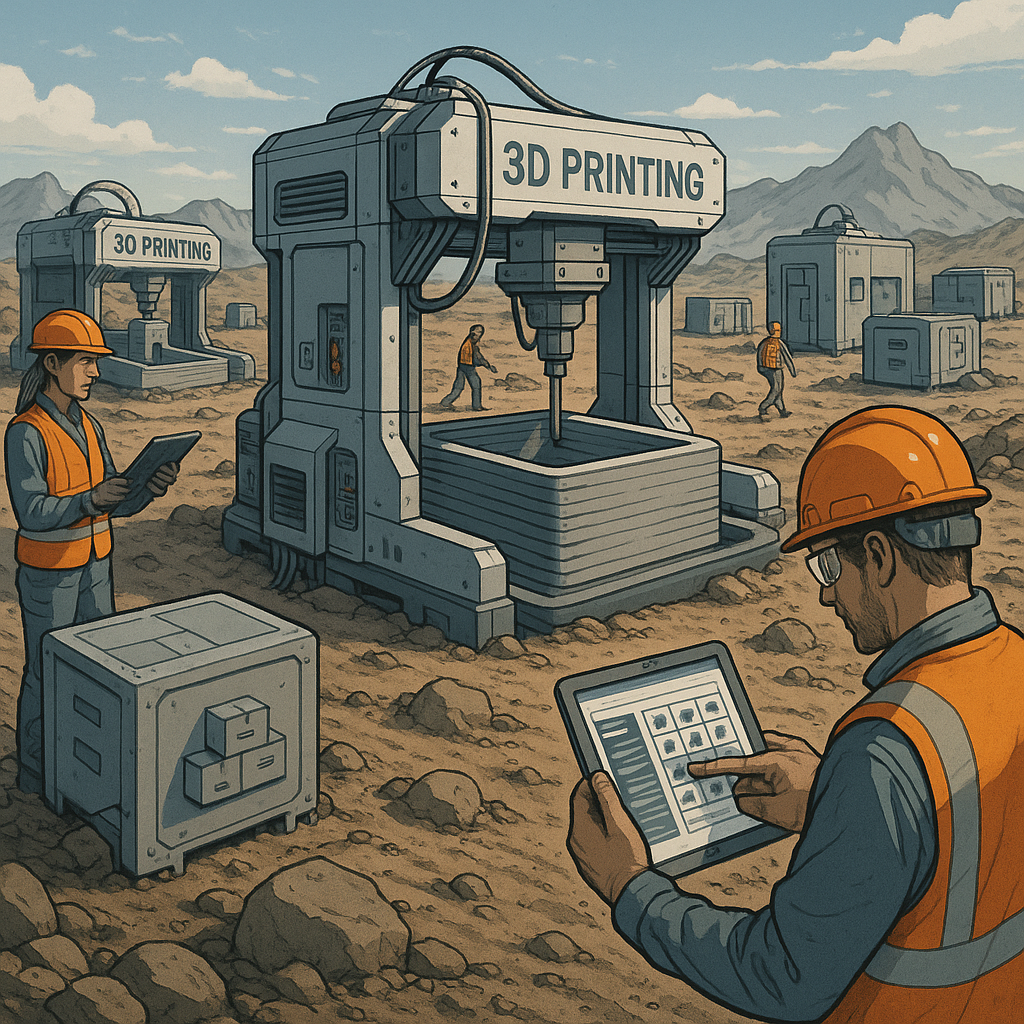

In a recent development covered by 3D Printing Industry, ForgeX has introduced a new approach to additive manufacturing by enabling on-site 3D printing directly in the field. This innovation marks a significant step in distributed manufacturing, where production capabilities are decentralized and brought closer to the point of demand.

What Happened

ForgeX has launched an on-site additive manufacturing platform designed to operate in field environments. Although specific technical details and deployment scale remain under wraps, the platform reportedly supports rapid production of parts and components without the need for centralized factories or extensive logistics chains. This approach leverages advanced 3D printing technologies to produce parts on demand, addressing supply chain delays and inventory challenges.

Why It Matters

The introduction of ForgeX’s field-ready additive manufacturing system is poised to disrupt traditional supply chain and inventory management models. By shifting production closer to the point of use, companies can reduce reliance on large physical inventories and long lead times. This aligns with the broader trend of distributed manufacturing, which emphasizes agility, customization, and resilience in production networks.

For industries such as aerospace, defense, energy, and remote infrastructure maintenance, the ability to manufacture parts on-site can drastically improve operational uptime and reduce costs associated with storage and transportation. It also supports sustainability goals by minimizing waste and lowering emissions linked to shipping.

Technical Context

While the exact hardware and software specifications of ForgeX’s solution are not fully disclosed, the platform likely integrates robust, industrial-grade 3D printers capable of handling diverse materials suitable for field conditions. The system may include modular units with environmental controls to ensure print quality in variable settings.

Software integration is another critical component. Effective on-site manufacturing requires seamless digital inventory management, remote monitoring, and secure file transfer protocols to ensure the right parts are produced with traceability and quality assurance. ForgeX’s solution presumably incorporates these elements to support end-to-end production workflows.

This approach builds upon existing trends in additive manufacturing such as advanced materials development, improved printer reliability, and enhanced digital thread connectivity, enabling manufacturers to confidently move production out of centralized factories.

Near-Term Prediction Model

Over the next 12 to 24 months, ForgeX’s on-site additive manufacturing platform is expected to progress through pilot deployments and early commercial adoption. Initial use cases will likely focus on industries with critical uptime needs and remote operations, such as oil & gas, military logistics, and emergency services.

As operational data accumulates, ForgeX and its partners will refine the technology’s robustness, material capabilities, and integration with enterprise resource planning (ERP) and digital inventory systems. Broader adoption will depend on demonstrating cost-effectiveness, print quality consistency, and ease of use in challenging environments.

We anticipate incremental expansion of distributed manufacturing networks leveraging ForgeX’s technology, catalyzing a shift from traditional inventory stocking toward more dynamic, on-demand production models.

What to Watch

- Material Compatibility: Expansion of printable materials suitable for diverse field applications will be key to broadening ForgeX’s market reach.

- Software Ecosystem: Development of secure, user-friendly digital inventory and production management tools will influence adoption rates.

- Use Case Validation: Early success stories in sectors with stringent operational demands will build confidence in the technology.

- Regulatory and Quality Standards: Compliance with industry-specific standards for additive manufacturing parts will be critical for deployment in regulated environments.

- Partnerships and Ecosystem Growth: Collaborations with material suppliers, software developers, and end users will accelerate innovation and scale.

In summary, ForgeX’s initiative to bring additive manufacturing directly to the field represents a pivotal advancement in distributed manufacturing and digital inventory strategies. While some technical and commercial details remain to be disclosed, the potential impact on supply chain agility and operational resilience is substantial. Stakeholders should monitor the evolution of this platform closely as it moves from pilot to broader commercialization.