What Happened

In a significant advancement for the field of embedded 3D printing, a 2023 research article published in Advanced Functional Materials by Shin et al. details a novel approach to achieve gelation of uniform interfacial diffusants within embedded 3D printing processes. This work focuses on the controlled gelation mechanisms that enable precise and stable diffusion interfaces during printing, addressing a critical challenge in creating complex bio-embedded and smart material constructs.

Why It Matters

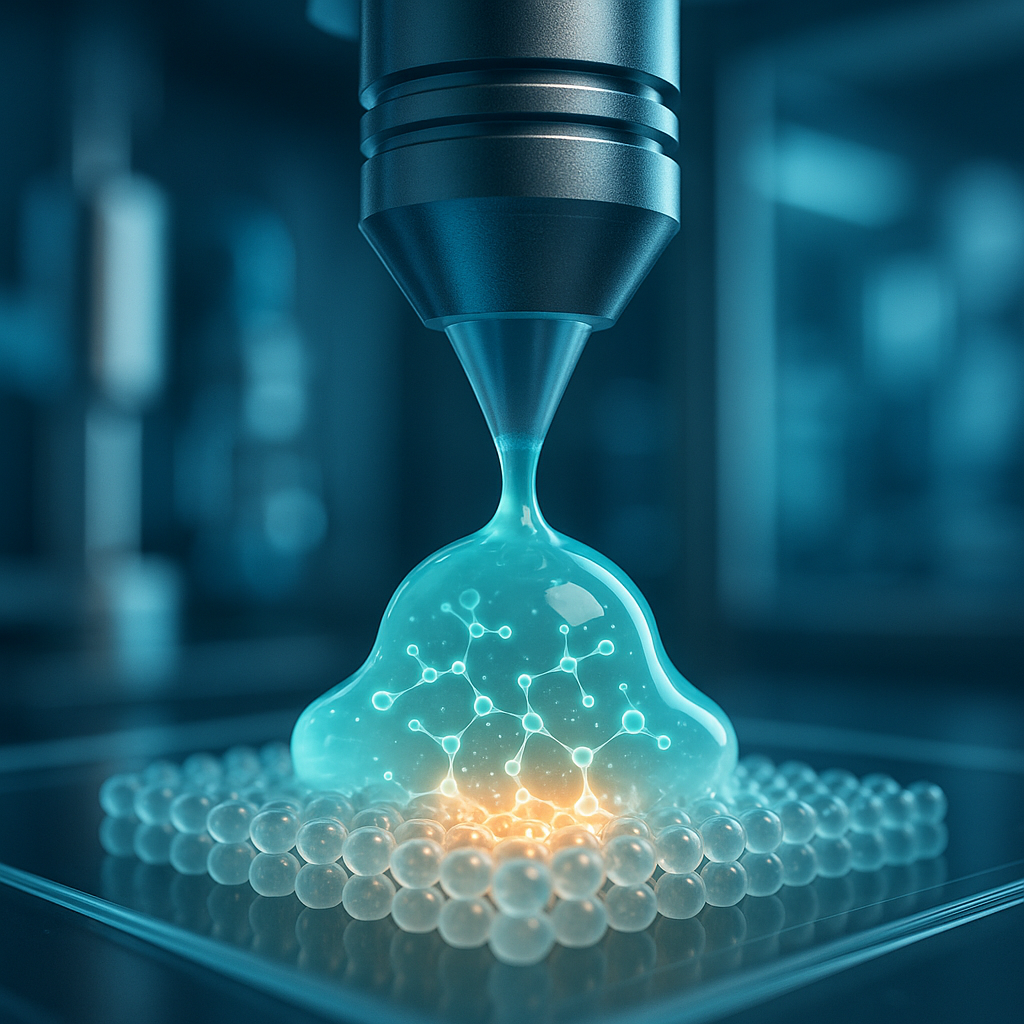

Embedded 3D printing is a transformative manufacturing technique that allows for the direct fabrication of materials within a supporting matrix, often enabling the creation of soft, bio-compatible, and multifunctional structures. However, controlling the diffusion and solidification—gelation—of materials at interfaces has remained a technical bottleneck. The uniform gelation of interfacial diffusants as demonstrated by Shin’s team is crucial because it ensures structural integrity, reproducibility, and functional performance of printed constructs, especially when dealing with sensitive biological or smart materials. This could accelerate the development of advanced tissue engineering scaffolds, wearable biosensors, and responsive soft robotics.

Technical Context

Embedded 3D printing typically involves extruding a material into a support bath or matrix that stabilizes the printed form during fabrication. The interfacial region between the extruded ink and the surrounding medium is a zone of complex chemical and physical interactions, especially when diffusants—molecules or particles that migrate across the interface—are involved. Uncontrolled diffusion can lead to irregular gelation, poor mechanical properties, and loss of functional gradients essential for bio-embedded applications.

Shin et al.’s study introduces a method to uniformly control the gelation process by manipulating the diffusant’s behavior at the interface. Although the exact chemical composition and gelation kinetics details are not fully disclosed in the summary, it is implied that the research leverages precise control over interfacial chemistry and diffusion dynamics to achieve consistent gel formation. This approach likely involves tuning parameters such as diffusant concentration, temperature, pH, and possibly crosslinking agents within the embedded printing environment.

Near-term Prediction Model

In the next 12 to 24 months, the principles demonstrated by Shin’s research are expected to transition from laboratory-scale proof-of-concept to pilot-scale implementations within specialized research and development settings. Early adopters will likely be academic and industrial labs focused on biofabrication, regenerative medicine, and smart material development. The technology maturity is currently at the R&D stage, with an impact score estimated at 75 out of 100 due to its potential to solve persistent challenges in embedded printing but tempered by the need for further validation and scalability assessment.

Confidence in this prediction is moderate (around 65%) because while the fundamental science is promising, practical deployment depends on reproducibility, material compatibility, and integration with existing 3D printing platforms. Key risks include difficulties in scaling the gelation uniformity to larger or more complex geometries, potential incompatibilities with diverse bioinks or smart materials, and the need for specialized equipment to maintain controlled diffusion environments.

What to Watch

- Further publications or patents from Shin’s group or affiliated institutions that reveal detailed chemical formulations and process parameters.

- Demonstrations of embedded 3D printing constructs with enhanced mechanical and functional properties enabled by uniform interfacial diffusant gelation.

- Collaborations between material scientists and bioengineers to apply this gelation method in tissue engineering or biosensor fabrication.

- Commercialization efforts or startup ventures incorporating this technique into next-generation 3D printers or biofabrication platforms.

- Advances in in situ monitoring technologies that can verify gelation uniformity during the printing process.

Overall, Shin’s 2023 study marks a noteworthy stride in the smart and bio-embedded materials domain of 3D printing, providing a new pathway to overcome longstanding challenges related to interfacial control and material integration.