What Happened

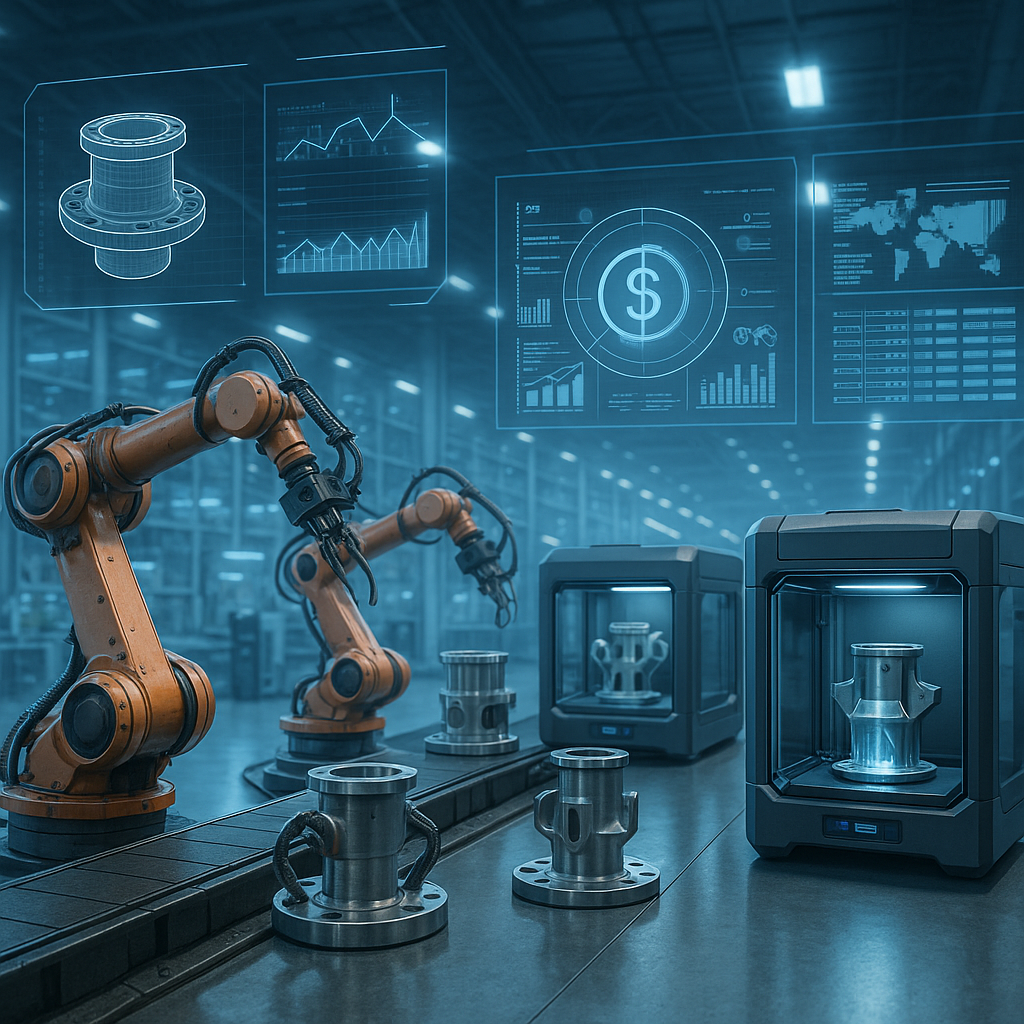

Siemens recently announced a significant development in the realm of digital inventory and on-demand manufacturing through its Xcelerator Marketplace. This platform enables the direct production of 3D-printed parts within factory settings, effectively transforming traditional supply chains and inventory management models by embedding additive manufacturing capabilities on-site.

Why It Matters

The integration of 3D printing directly into factories represents a pivotal shift from centralized warehousing to a decentralized digital warehouse model. This approach reduces the need for physical stockpiles of spare parts and components by enabling on-demand production, which can dramatically cut lead times and inventory costs. For industries reliant on complex supply chains, this innovation promises enhanced responsiveness and resilience, particularly in mitigating disruptions caused by logistics delays or sudden demand spikes.

Moreover, the Siemens Xcelerator Marketplace acts as a digital hub, connecting design data, manufacturing resources, and supply chain logistics. This digital warehouse concept aligns with Industry 4.0 trends, where data-driven agility and flexible production are essential for competitive advantage.

Technical Context

The Siemens Xcelerator Marketplace leverages advanced additive manufacturing technologies integrated with digital twin simulations, AI-driven production planning, and cloud-based design repositories. Factories equipped with compatible 3D printers can access a catalog of validated digital part files and produce components on demand, eliminating the traditional manufacturing bottlenecks related to tooling and batch production.

While specific technical details such as supported materials, printer models, and software interoperability remain undisclosed, the platform likely utilizes Siemens’ extensive expertise in industrial automation and digitalization to ensure seamless integration with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) software.

Near-term Prediction Model

In the next 12 to 24 months, the adoption of factory-direct 3D printing via the Siemens Xcelerator Marketplace is expected to progress from pilot implementations to broader commercial deployment, particularly in sectors such as automotive, aerospace, and industrial machinery where spare parts availability is critical.

Initial impacts will include reduced inventory carrying costs and improved service levels due to rapid part availability. As the ecosystem matures, we anticipate enhanced AI-driven production optimization and expanded material capabilities, further embedding digital warehouses into mainstream manufacturing operations.

What to Watch

- Material and Process Validation: Monitoring how Siemens ensures quality and certification standards for on-demand printed parts will be crucial, especially for safety-critical applications.

- Integration with Supply Chains: The extent to which the Xcelerator Marketplace can synchronize with global supply networks and logistics providers will determine its scalability and impact.

- Expansion of Part Catalogs: Growth in the variety and complexity of parts available for on-demand printing will signal market acceptance and technical progress.

- Competitive Responses: How other industrial software and manufacturing firms respond with similar digital warehouse solutions could accelerate innovation and adoption.

While many implementation specifics remain to be disclosed, Siemens’ initiative marks a clear step toward digitally empowered, flexible manufacturing that could redefine inventory paradigms across industries.