What Happened

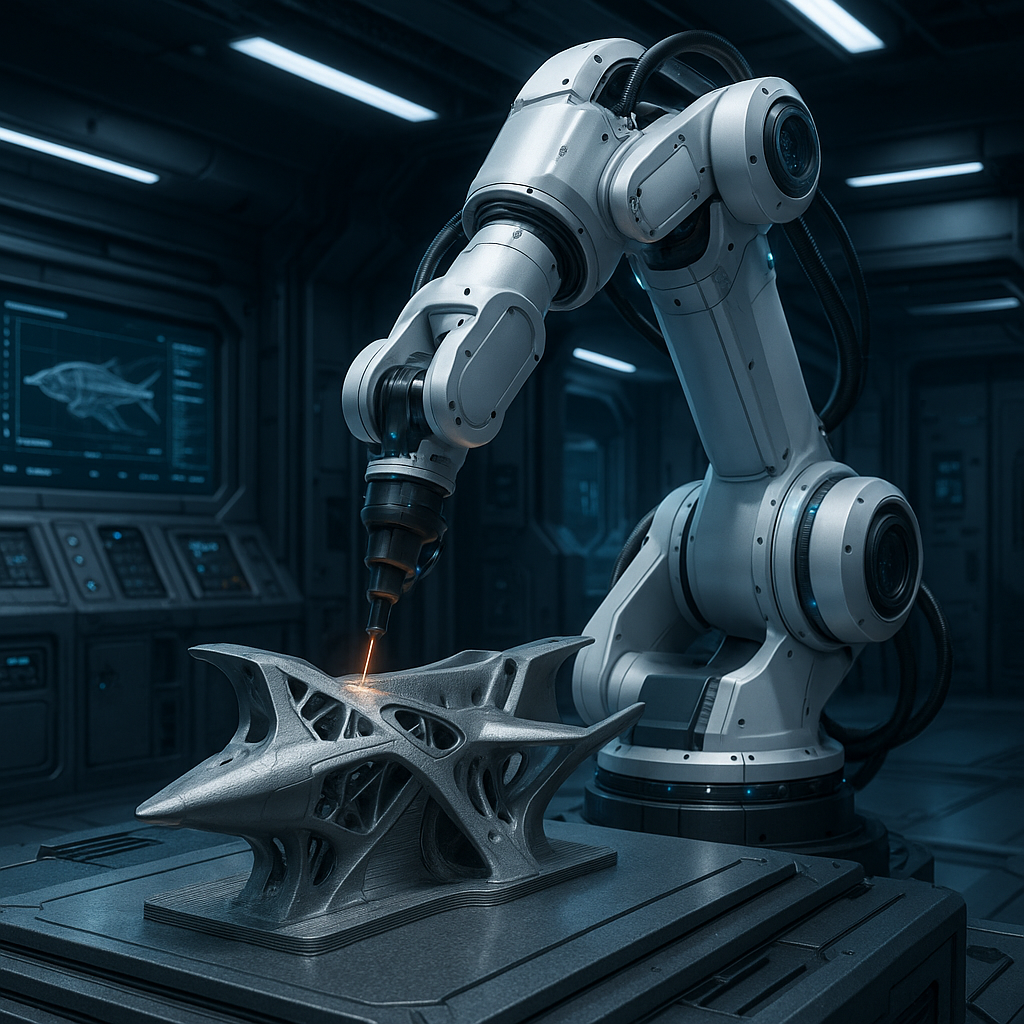

The Robins Air Force Base (AFB) additive manufacturing lab has recently made significant strides in advancing the United States Air Force’s readiness by integrating robotic arm 3D printing technologies. According to a report on robins.af.mil, the lab is leveraging robotic arms equipped with advanced additive manufacturing capabilities to produce complex aerospace components. While specific technical details remain limited in the public domain, this development marks a pivotal step towards employing non-planar and multi-axis 3D printing methods in military manufacturing contexts.

Why It Matters

Robotic arm 3D printing represents a transformative shift from traditional planar, layer-by-layer additive manufacturing. By enabling multi-axis and non-planar deposition paths, robotic arms can fabricate parts with superior mechanical properties, reduced support structures, and intricate geometries that are otherwise impossible or inefficient to produce. For the Air Force, this means faster production cycles, enhanced part performance, and the ability to rapidly prototype or replace critical components in operational settings.

Moreover, integrating these technologies within a military base’s manufacturing infrastructure underscores a strategic move towards decentralized, on-demand production capabilities. This enhances resilience and readiness by reducing dependency on external supply chains and enabling tailored manufacturing solutions directly at the point of need.

Technical Context

Robotic arm 3D printing utilizes articulated robotic manipulators capable of moving a print head or extrusion nozzle along multiple axes—commonly six or more degrees of freedom. This flexibility allows the print head to maintain optimal orientation relative to the build surface, enabling non-planar layer deposition. Compared to conventional 3D printers that build layer by layer on a fixed Z-axis, multi-axis robotic systems can print on curved surfaces, create smoother transitions between layers, and orient fibers or materials in directions that enhance strength.

These capabilities are especially valuable in aerospace manufacturing, where parts often require complex geometries and directional strength properties. The Robins AFB lab’s adoption of these systems likely involves advanced path planning algorithms, real-time monitoring, and possibly multi-material or metal additive manufacturing processes, although these specifics are not publicly disclosed.

Near-Term Prediction Model

Given the current state of robotic arm 3D printing and the military’s investment in additive manufacturing, it is expected that within the next 12 to 24 months, Robins AFB will transition from pilot-scale demonstrations to more routine production of mission-critical components using multi-axis printing. This timeline aligns with the broader aerospace industry’s gradual adoption of non-planar additive manufacturing for structural and functional parts.

Challenges remain in process standardization, quality assurance, and certification for flight-ready parts, but ongoing research and collaboration with industry partners will likely accelerate these developments. The impact on Air Force readiness scores could be significant, with improved turnaround times for spare parts and enhanced capability to innovate on-demand.

What to Watch

- Technical disclosures: Look for detailed technical papers or presentations from Robins AFB or affiliated contractors that reveal the specific robotic arm configurations, materials, and process control strategies being employed.

- Certification milestones: Monitor progress toward qualifying multi-axis 3D printed parts for flight use, including testing regimes and regulatory approvals.

- Expansion of applications: Observe whether the technology extends beyond prototyping to full-scale manufacturing of engine components, airframe parts, or tooling.

- Integration with digital manufacturing: Watch for advances in software integration, including AI-driven path planning and in-situ monitoring, which are critical for scaling multi-axis printing.

- Collaborations and funding: Track partnerships between military labs, universities, and industry leaders that may accelerate innovation and deployment.

In summary, Robins AFB’s additive manufacturing lab is at the forefront of implementing robotic arm 3D printing technology to enhance Air Force operational readiness. While many technical specifics remain undisclosed, the strategic implications for aerospace manufacturing and military logistics are profound, heralding a new era of flexible, high-performance additive manufacturing.