What Happened

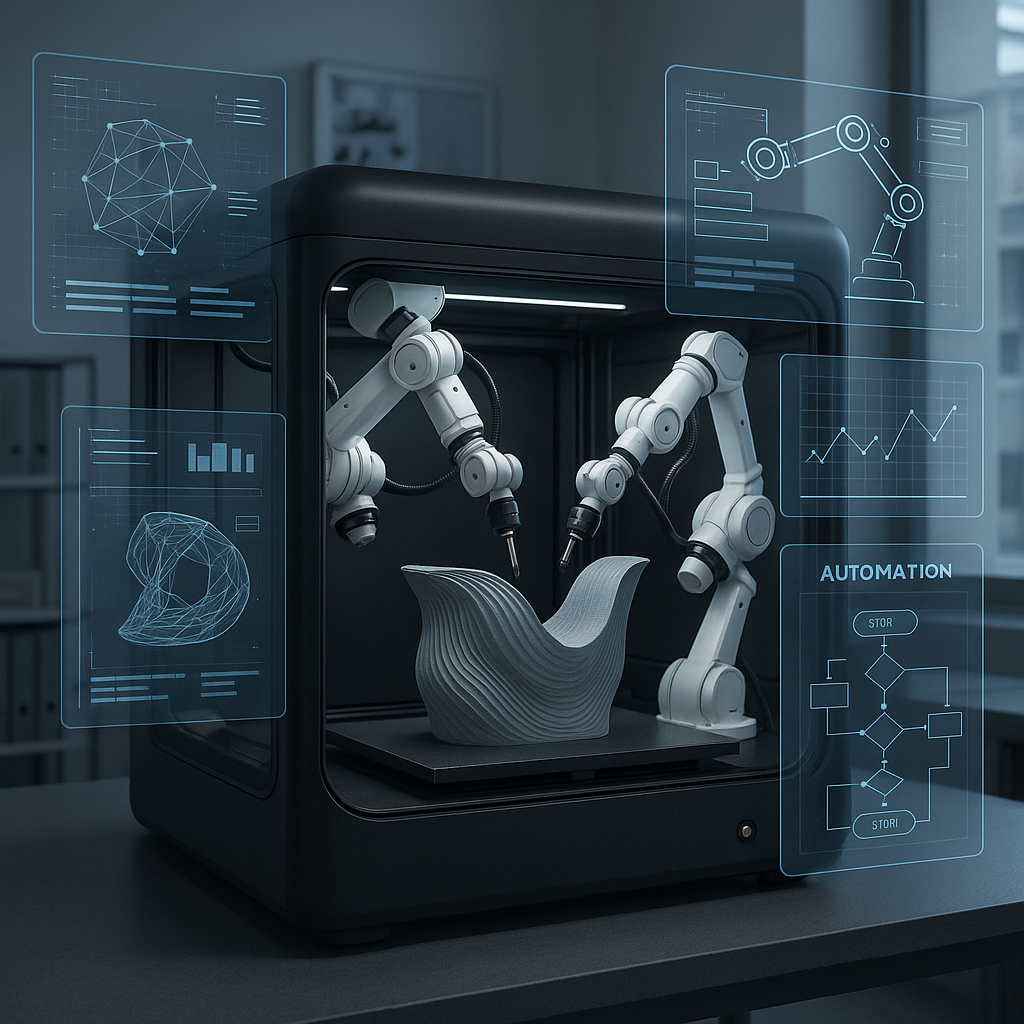

In a significant development for the non-planar and multi-axis 3D printing community, Aibuild and Generative Machine have unveiled a novel desktop 3D printing system that integrates 5-axis fused filament fabrication (FFF) with advanced automation software. This breakthrough brings multi-axis additive manufacturing—traditionally confined to large industrial machines—into the desktop segment, promising enhanced print quality and geometric freedom.

Why It Matters

FFF 3D printing has long been dominated by planar, 3-axis systems where the print head moves along X, Y, and Z axes. While effective, this approach limits the ability to print complex geometries without support structures and often results in anisotropic mechanical properties due to layer stacking. The introduction of 5-axis FFF at the desktop level addresses these challenges by allowing the print head or the build platform to rotate and tilt, enabling continuous, non-planar deposition paths.

This advancement is critical because it can reduce or eliminate the need for support structures, improve surface finish by following part contours, and enhance mechanical strength by aligning filament paths with stress directions. Moreover, the accompanying automation software developed by Generative Machine is designed to streamline the complex toolpath generation and machine control required for multi-axis printing, making this technology more accessible to end users.

Technical Context

Multi-axis additive manufacturing has been explored in industrial settings with metal powder bed fusion and large-format polymer extrusion systems, but desktop FFF implementations have been rare due to mechanical complexity and software limitations. The 5-axis system introduced by Aibuild and Generative Machine likely uses a combination of rotational and translational axes to manipulate the print head or build platform, enabling deposition from multiple angles.

The automation software is a key enabler, as generating efficient, collision-free toolpaths for 5-axis extrusion is non-trivial. Traditional slicers are designed for planar layer-by-layer printing, so this software must incorporate advanced algorithms for non-planar slicing, motion planning, and synchronization of multiple degrees of freedom. Details about the specific hardware architecture, degrees of freedom, and software algorithms remain undisclosed at this time.

Near-term Prediction Model

Given the novelty and technical complexity, the technology is likely transitioning from pilot to early commercial stages within the next 12 to 18 months. Early adopters will include research labs, advanced prototyping facilities, and specialized manufacturers seeking improved mechanical properties and design freedom. The impact score is moderate to high (around 70/100) because while the technology addresses significant limitations of planar FFF, widespread adoption will depend on cost, reliability, and ease of use.

Confidence in the technology’s potential is moderate (around 65/100) due to the challenges of multi-axis motion control, filament extrusion synchronization, and software maturity. Key risks include mechanical reliability, print speed trade-offs, and the learning curve for users transitioning from conventional 3-axis systems.

What to Watch

- Further technical disclosures from Aibuild and Generative Machine regarding hardware design and software capabilities.

- Demonstrations and case studies showcasing mechanical property improvements and geometric complexity enabled by 5-axis FFF.

- Integration of this technology with existing desktop 3D printing ecosystems and material compatibility expansions.

- Adoption trends among industrial users and feedback on usability and print quality.

- Development of open standards or third-party software support for multi-axis FFF slicing and toolpath generation.

This development marks an exciting frontier for desktop additive manufacturing, potentially bridging the gap between industrial multi-axis printing capabilities and accessible desktop platforms.