What Happened

ÖBB-TS, the technical services division of Austria’s national railway operator, has announced a strategic partnership with 3D Spark to bolster its digital spare parts strategy. This collaboration aims to leverage 3D printing technology to create a more agile and efficient digital warehouse for on-demand production of railway components. Details of the partnership and its implications were reported by 3D Printing Industry.

Why It Matters

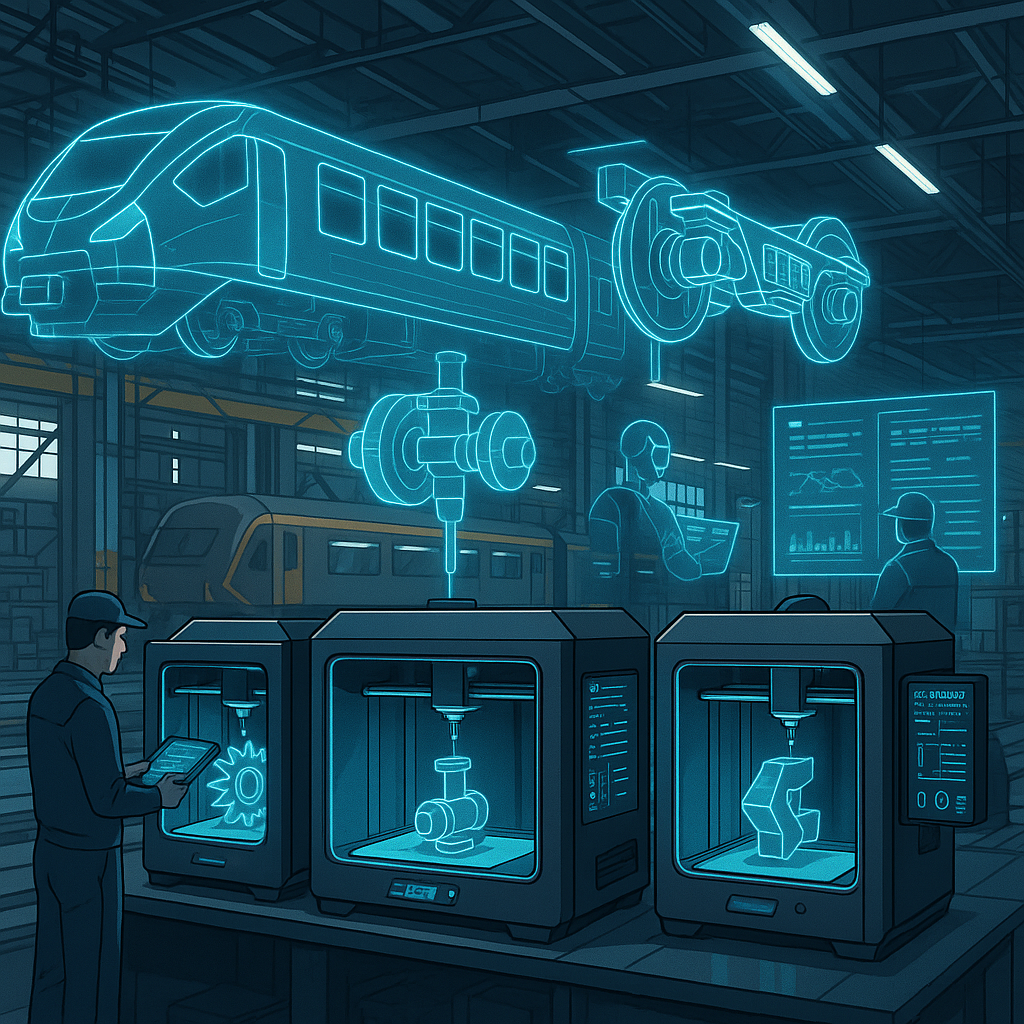

Railway operators face significant challenges in maintaining complex fleets with a vast array of spare parts, many of which are obsolete or have long lead times. Traditional warehousing of these parts is costly and inefficient. ÖBB-TS’s move to integrate 3D printing through 3D Spark’s platform creates a digital warehouse — a virtual inventory of digital part files that can be printed on demand close to the point of need.

This approach reduces physical inventory costs, shortens downtime by accelerating part availability, and enables the production of discontinued or customized components. For the railway sector, where safety and reliability are paramount, such a digital inventory strategy represents a transformative shift in supply chain management and maintenance logistics.

Technical Context

The partnership likely involves 3D Spark providing a secure, cloud-based platform to manage digital part files and coordinate distributed manufacturing. ÖBB-TS can select parts from a validated digital inventory and trigger production at local 3D printing facilities, potentially including in-house or partner workshops.

While the specific additive manufacturing technologies and materials used have not been disclosed, railway spare parts typically require metals or high-performance polymers that meet stringent mechanical and safety standards. The integration of digital inventory management with quality control and certification processes is critical to ensure that on-demand printed parts comply with regulatory requirements.

Currently, details such as the scope of parts covered, print technologies employed, and scale of deployment remain unknown. However, this initiative aligns with broader industry trends toward decentralization of manufacturing and the use of digital twins for asset lifecycle management.

Near-term Prediction Model

ÖBB-TS and 3D Spark’s digital warehouse concept is positioned at the pilot to early commercial maturity stage. Within the next 12 to 24 months, we anticipate incremental expansion of the digital spare parts portfolio and increased operational integration.

The impact score is estimated at 75/100, reflecting significant potential to reduce inventory costs and improve maintenance responsiveness, balanced with challenges around certification, part qualification, and scaling production capacity. Confidence in the initiative’s success is moderate at 70/100, given the nascent state of widespread adoption in railway maintenance.

What to Watch

- Expansion of the digital inventory catalog: which parts and components become available for on-demand printing.

- Material and process certification: how ÖBB-TS ensures printed parts meet safety and regulatory standards.

- Integration with existing maintenance workflows: adoption by technicians and impact on repair turnaround times.

- Scaling of distributed manufacturing network: growth of print facilities and geographic coverage.

- Development of digital twin and predictive maintenance tools that complement the digital warehouse strategy.

In conclusion, ÖBB-TS’s partnership with 3D Spark exemplifies the growing momentum behind digital warehouses and on-demand 3D printing in industrial supply chains. While several implementation details remain to be seen, this initiative is a promising example of how additive manufacturing can revolutionize spare parts logistics in complex, safety-critical sectors like railways.