Harvard researchers have made significant strides in robotic arm 3D printing techniques aimed at fabricating programmable soft robots, as reported by VoxelMatters. This development leverages the flexibility of robotic arms to perform multi-axis, non-planar 3D printing, enabling the creation of complex soft robotic structures with programmable mechanical properties.

What Happened

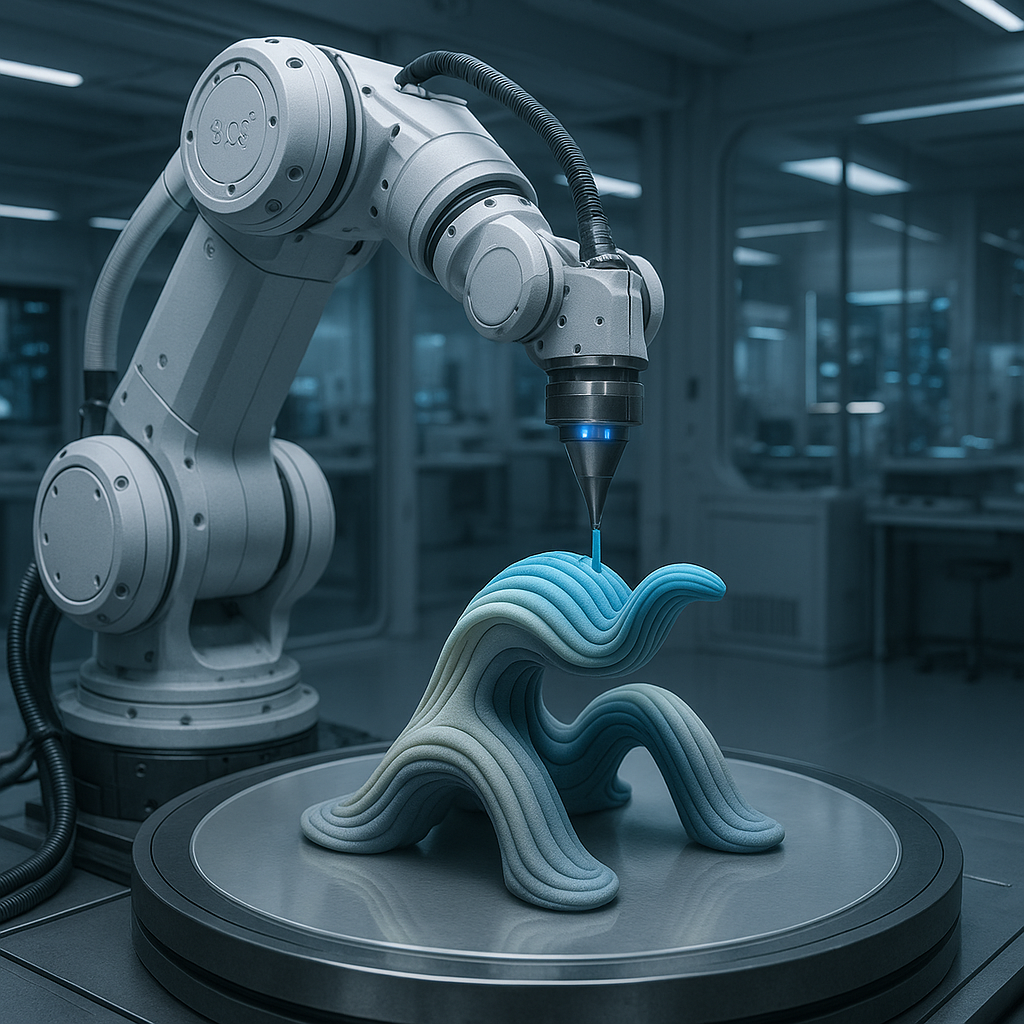

The Harvard team extended existing 3D printing methods by integrating robotic arms capable of depositing materials along curved, three-dimensional paths rather than traditional planar layers. This approach allows for the fabrication of soft robots that can be programmed to respond dynamically to stimuli through embedded mechanical gradients and anisotropies. The research focuses on overcoming the limitations of planar layer-by-layer printing by utilizing the dexterity of robotic arms to manipulate print paths in multiple axes, thus enabling more intricate geometries and functional gradations within the printed parts.

Why It Matters

This advancement is pivotal for the field of soft robotics and additive manufacturing because it addresses two key challenges: the ability to produce soft robotic components with complex, programmable behaviors, and the need for more versatile 3D printing methods beyond planar constraints. Traditional 3D printing methods are limited in creating anisotropic or gradient material properties, which are essential for soft robots to perform nuanced movements and functions. By using robotic arms for multi-axis printing, the researchers open pathways to more biomimetic, adaptable soft robots that can be customized at the material and structural level.

Technical Context

Robotic arm 3D printing represents a frontier in multi-axis additive manufacturing. Unlike conventional Cartesian 3D printers that operate primarily in three perpendicular axes (X, Y, Z), robotic arms add rotational degrees of freedom, allowing the print head to approach the build from various angles and orientations. This capability facilitates non-planar printing, where layers are not restricted to flat planes but can follow complex surfaces or curves.

In the context of programmable soft robots, this means materials can be deposited with spatial control over fiber orientation, density, and composition, directly influencing the mechanical response of the printed structure. The Harvard researchers likely employed advanced slicing algorithms and material extrusion techniques tailored for robotic arms to achieve precise deposition and curing of soft, elastomeric materials embedded with functional gradients.

While specific technical details such as the exact robotic arm model, materials used, or software frameworks remain undisclosed in the source article, the approach aligns with emerging trends in multi-axis printing and soft robotics fabrication.

Near-Term Prediction Model

This technology is currently in the R&D stage, with promising potential to transition into pilot projects within the next 12 to 24 months. The impact score is estimated at 75 out of 100, reflecting its ability to significantly enhance soft robot fabrication but acknowledging challenges in scaling and material integration. Confidence in the prediction is moderate at 70 out of 100 due to unknowns around manufacturing robustness and commercial viability.

What to Watch

- Development of standardized materials compatible with robotic arm multi-axis printing for soft robotics.

- Advancements in slicing software and path planning algorithms that optimize non-planar deposition for functional gradients.

- Demonstrations of fully functional soft robots fabricated via this method performing complex tasks.

- Integration of sensing and actuation elements during printing to further enhance programmability.

- Collaborations between academic researchers and industry players to commercialize this approach.

In summary, the Harvard research pushes the boundaries of robotic arm 3D printing by enabling programmable soft robots with complex material and structural properties. This progress marks a critical step toward more adaptable, biomimetic soft robotic systems and exemplifies the transformative potential of multi-axis, non-planar additive manufacturing.