What Happened

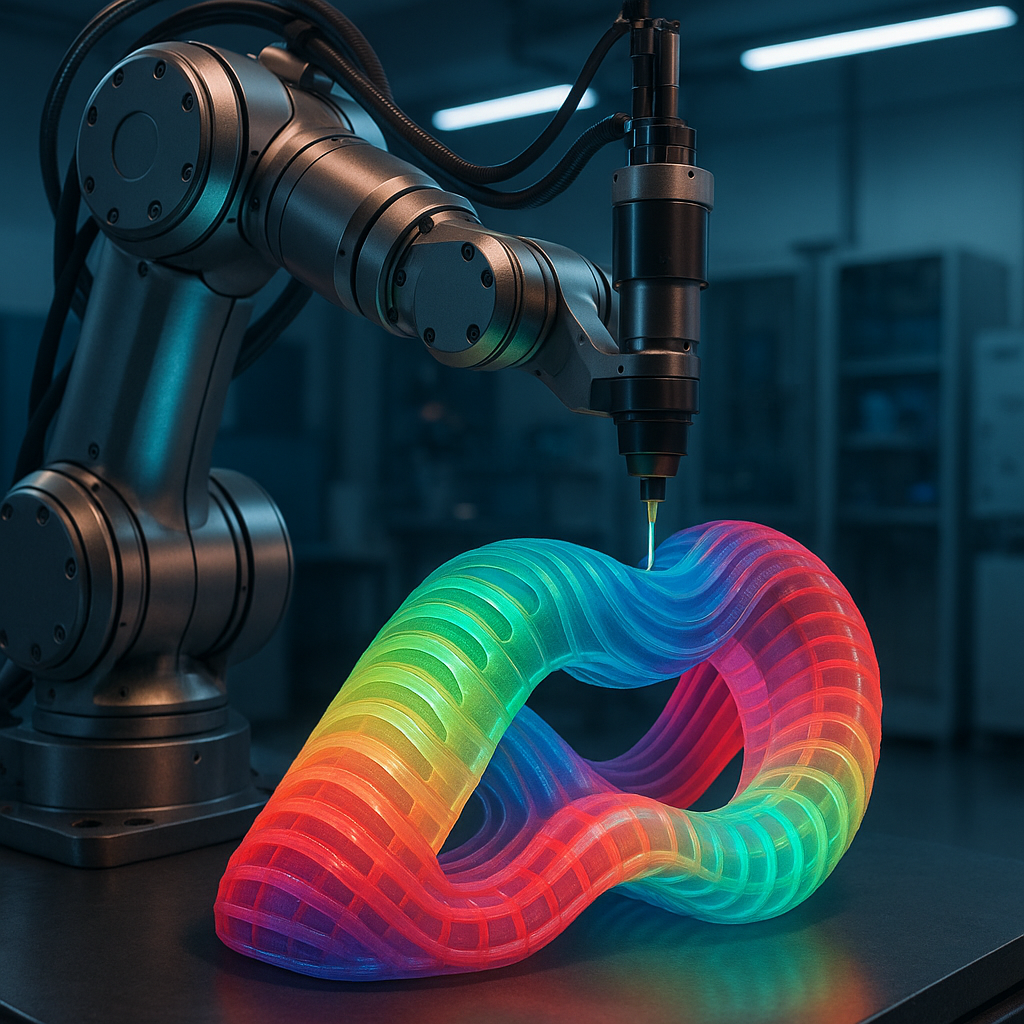

Harvard researchers have made significant progress in robotic arm 3D printing methods to fabricate programmable soft robots, as reported by VoxelMatters. This advancement leverages multi-axis, non-planar 3D printing techniques enabled by robotic arms, allowing complex geometries and material programming within soft robotic constructs.

Why It Matters

Traditional 3D printing is largely planar, limiting the complexity and functional integration of printed objects. The use of robotic arms introduces multi-axis capabilities that allow printing on curved surfaces and dynamic orientations, which is critical for soft robotics where flexibility and embedded programmability are essential. This technology can revolutionize the design and manufacturing of soft robots capable of adaptive, programmable behaviors, opening new applications in biomedical devices, wearable tech, and responsive materials.

Technical Context

Conventional fused filament fabrication and resin-based 3D printing mostly operate layer-by-layer on flat planes, restricting the mechanical properties and design freedom. Robotic arm 3D printing utilizes six or more degrees of freedom, enabling non-planar deposition paths that conform to complex 3D surfaces. This approach supports the integration of multiple materials and programmable elements within a single print, essential for soft robotics that require graded stiffness, embedded sensors, and actuators.

Harvard’s work likely involves advanced toolpath planning algorithms, precise motion control, and material extrusion techniques compatible with soft, elastomeric polymers. While the exact materials and printing parameters are not detailed in the source, the focus on programmable soft robots suggests the use of stimuli-responsive materials or embedded control architectures.

Near-term Prediction Model

This technology is currently in the research and development stage, with promising pilot demonstrations expected within 12 to 24 months. Commercial adoption will depend on scalability, material development, and integration with control systems. The impact score is high due to the potential to redefine soft robotics manufacturing, but confidence remains moderate given the complexity of multi-material printing and programmability challenges.

What to Watch

- Development of robust multi-material feedstocks suitable for robotic arm extrusion.

- Advances in real-time path planning and feedback control for non-planar, multi-axis printing.

- Integration of embedded sensors and actuators within printed soft robots.

- Demonstrations of programmable soft robots performing complex tasks or adaptive behaviors.

- Collaborations between academia and industry to transition the technology from lab to commercial applications.

Overall, Harvard’s progress in robotic arm 3D printing for programmable soft robots signals a transformative shift in additive manufacturing, enabling new classes of intelligent, flexible machines.