What Happened

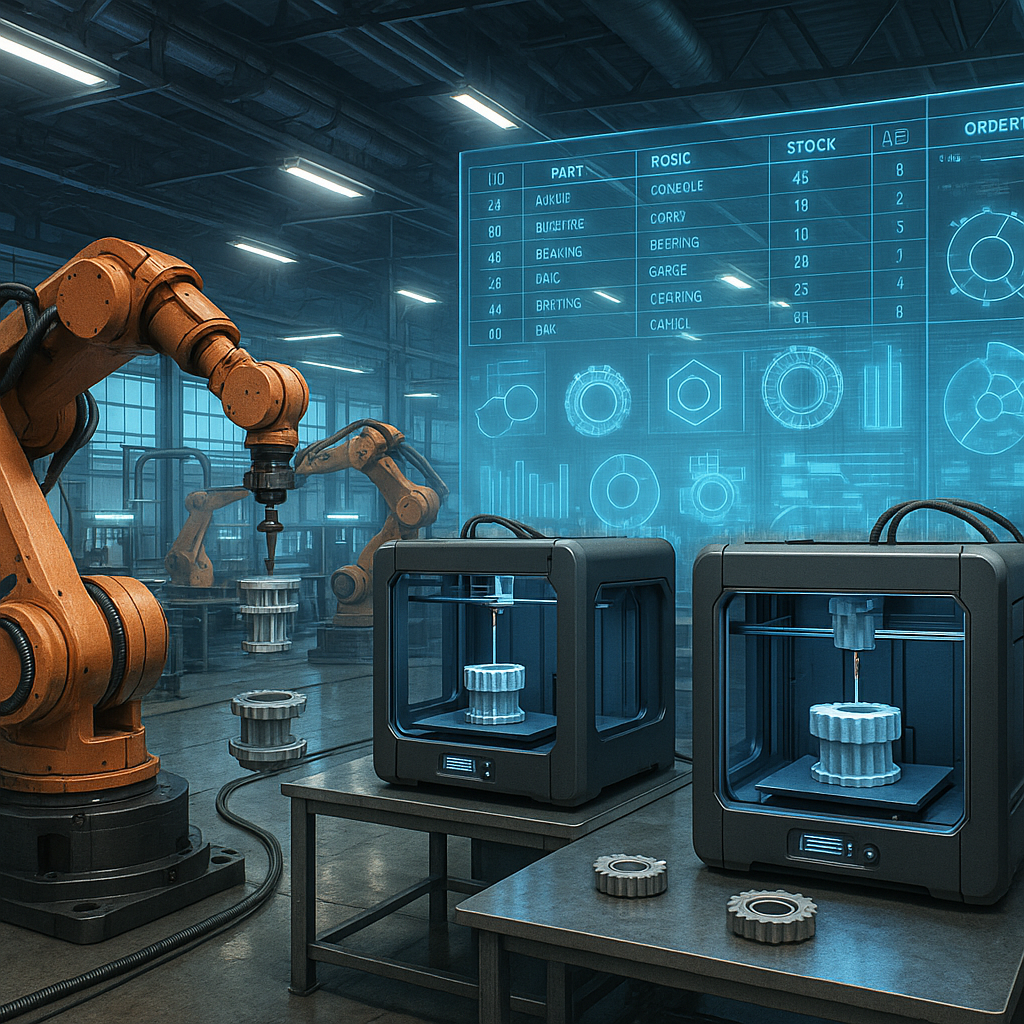

Formlabs, a leading player in the 3D printing industry, is set to launch Form Now, its own 3D printing service, according to a recent report by VoxelMatters published on September 18, 2025. This new service aims to provide customers with on-demand manufacturing capabilities, particularly focusing on producing spare parts and components rapidly when and where needed, effectively supporting digital inventory strategies.

Why It Matters

The launch of Form Now is significant because it directly addresses persistent challenges in supply chains and inventory management. Traditional inventory systems require maintaining large stocks of spare parts, which is costly and often inefficient, especially for low-volume or legacy components. By leveraging on-demand 3D printing, Formlabs is enabling businesses to reduce physical inventory, cut lead times, and respond more flexibly to maintenance and repair needs.

This shift is particularly relevant for industries reliant on spare parts with long life cycles or complex supply chains, such as aerospace, automotive, and industrial equipment. Form Now could reduce downtime by providing faster access to parts, while also lowering warehousing costs and minimizing waste from obsolete inventory.

Technical Context

Formlabs is known for its high-resolution stereolithography (SLA) and selective laser sintering (SLS) 3D printers, which are capable of producing parts with fine detail and functional properties suitable for end-use applications. The Form Now service likely leverages this technology backbone, combined with digital workflow software, to enable customers to upload digital part files and order printed spares on demand.

However, specific technical details about Form Now remain undisclosed at this time, including the range of materials supported, part size limits, turnaround times, and quality assurance processes. It is also unclear how Formlabs plans to integrate this service with existing enterprise resource planning (ERP) or inventory management systems, which would be critical for seamless digital inventory adoption.

Near-term Prediction Model

In the next 12 to 18 months, Form Now is expected to enter the commercial stage, initially targeting early adopters in industries with acute spare parts challenges. Adoption rates will depend on Formlabs’ ability to demonstrate consistent part quality, competitive pricing, and integration capabilities.

The impact of Form Now on the broader digital inventory and on-demand spares landscape could be substantial, accelerating the shift away from traditional stockpiling. However, challenges such as material certification, part qualification, and intellectual property management will influence the pace and scale of adoption.

What to Watch

- Service Capabilities: Monitor announcements regarding supported materials, part size, and quality standards to assess Form Now’s suitability for critical spare parts.

- Integration Features: Look for developments on software integration with enterprise systems to streamline ordering and inventory management workflows.

- Customer Case Studies: Early success stories or pilot programs will provide insight into real-world performance and ROI.

- Competitive Responses: Observe how other 3D printing service providers and traditional spare parts suppliers react to Formlabs’ move.

- Regulatory and Certification Developments: Watch for progress in industry-specific part certifications that could enable wider adoption.

While Form Now’s precise operational details remain to be fully revealed, its launch signals a growing maturity in on-demand 3D printing services that could redefine digital inventory management and spare parts logistics.