What Happened

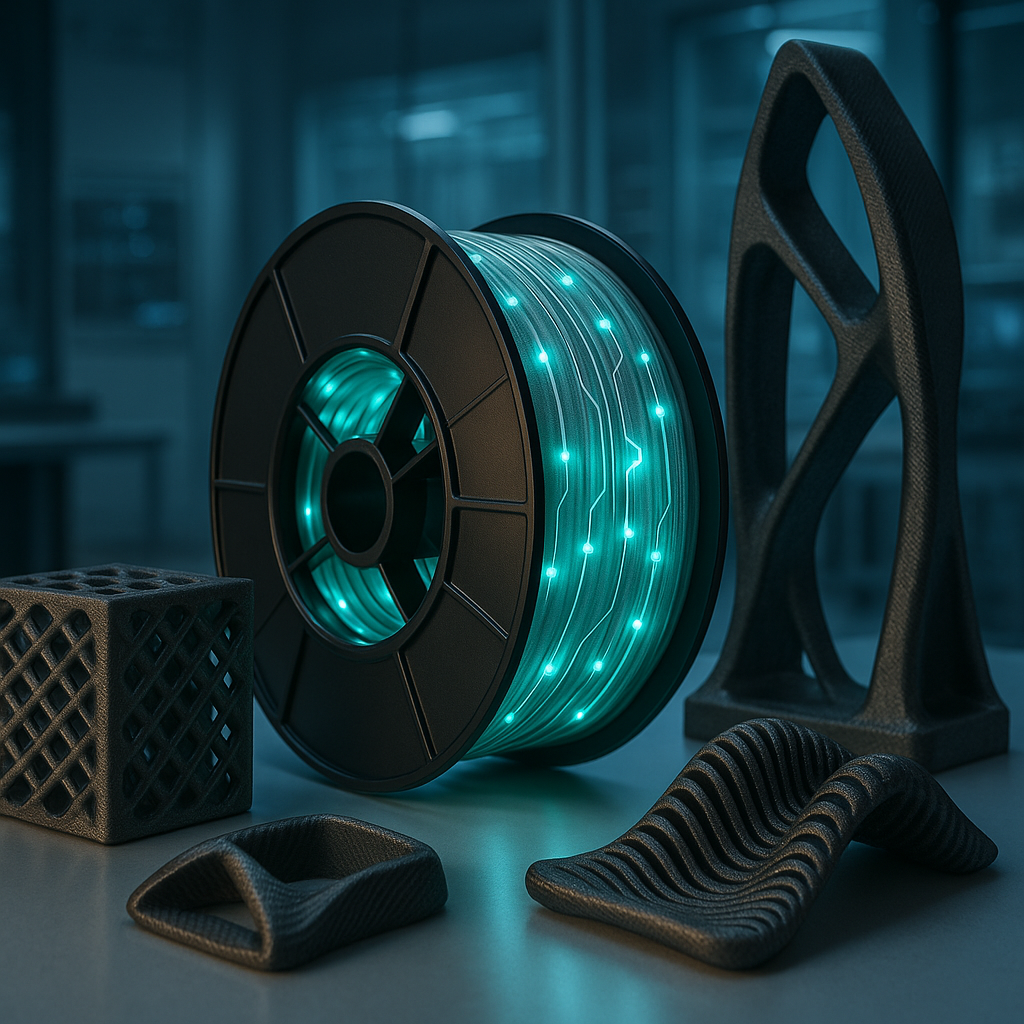

Elegoo has introduced a new series of fiber-reinforced filaments designed to enhance the strength, intelligence, and versatility of fused deposition modeling (FDM) 3D printing. This launch, reported by prnewswire.co.uk on June 24, 2025, marks a significant step forward in smart filament development by combining fiber reinforcement with embedded intelligence.

Why It Matters

The integration of fiber reinforcement into smart filaments addresses two key challenges in FDM 3D printing: mechanical performance and functional adaptability. Traditional filaments often struggle with strength and durability, limiting their use in demanding applications. Meanwhile, smart filaments—materials embedded with sensors or responsive elements—have been constrained by their mechanical limitations. Elegoo’s new filament series promises to overcome these hurdles, enabling the production of parts that are not only stronger but also capable of sensing or adapting to their environment.

This development could broaden the scope of FDM 3D printing from prototyping and hobbyist use to industrial applications requiring robust, multi-functional components. The ability to print smarter, tougher parts could impact sectors ranging from automotive and aerospace to healthcare and wearable technology.

Technical Context

Fiber-reinforced filaments typically incorporate materials such as carbon fiber, glass fiber, or aramid fibers into a polymer matrix to improve tensile strength, stiffness, and heat resistance. Elegoo’s new series enhances this approach by embedding smart functionalities, although specific details about the nature of the intelligence—whether it involves embedded sensors, conductive pathways, or responsive polymers—are currently undisclosed.

The challenge lies in balancing fiber content to maximize strength without compromising printability or the smart features. Excessive fiber can cause nozzle clogging or poor layer adhesion, while integrating sensors requires precise control over material composition and extrusion parameters. Elegoo’s achievement suggests advancements in filament formulation and manufacturing processes that maintain compatibility with standard FDM printers.

Additionally, the smart aspect implies potential integration of bio-embedded materials or responsive elements that could interact with environmental stimuli such as temperature, stress, or chemical exposure. This aligns with broader trends in 3D printing toward multifunctional materials that combine structural and sensory roles.

Near-term Prediction Model

Given the current announcement and the known challenges of fiber-reinforced and smart filaments, this technology is positioned at the early commercial stage. Elegoo, a recognized player in the 3D printing market, is likely targeting both prosumers and industrial users seeking enhanced material performance.

Within the next 12 to 18 months, we can expect:

- Expanded availability of the filament series with detailed technical datasheets and user guidelines.

- Community and industrial feedback that will refine printing parameters and reveal practical strengths and limitations.

- Early adoption in niche applications such as functional prototypes, tooling aids, and sensor-integrated parts.

However, widespread adoption may require further improvements in cost-efficiency, printer compatibility, and smart feature robustness.

What to Watch

- Material Specifications: Detailed composition and smart functionality descriptions from Elegoo or independent testing labs.

- Printer Compatibility: Reports on how well the filament performs across different FDM machines, including any required hardware modifications.

- Application Case Studies: Real-world examples demonstrating the filament’s impact on product performance and new use cases.

- Competitive Responses: Developments from other filament manufacturers pursuing fiber-reinforced smart materials.

- Standardization and Certification: Progress toward industry standards that validate mechanical and smart properties for regulated sectors.

In conclusion, Elegoo’s fiber-reinforced smart filament series represents a promising convergence of strength and embedded intelligence in FDM 3D printing. While some technical specifics remain under wraps, the launch signals a maturing market for multifunctional smart materials that could redefine the capabilities and applications of desktop and industrial 3D printers.