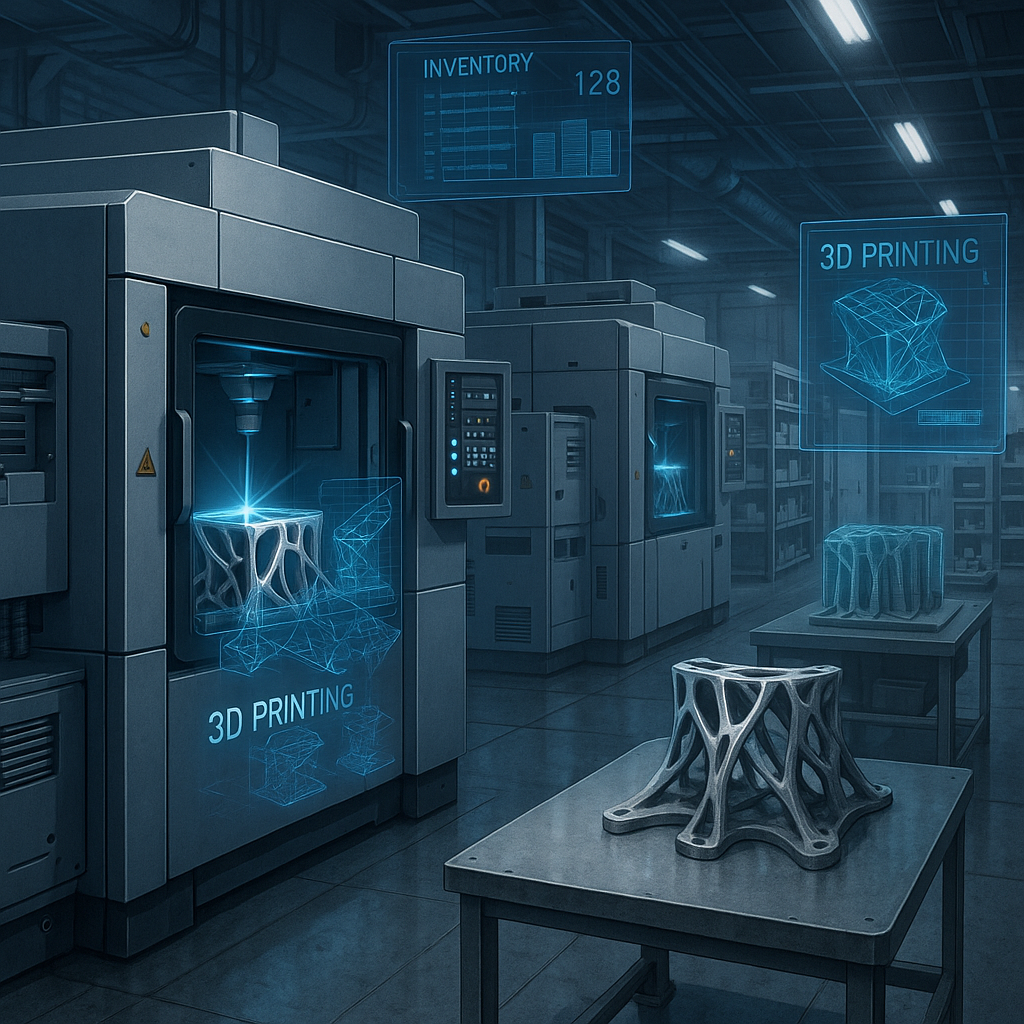

A recent expansion by a metal 3D printing manufacturer, reported by the Knoxville News Sentinel, highlights a pivotal shift in advanced manufacturing. This development underscores the growing role of metal additive manufacturing technologies in enabling distributed manufacturing and digital inventory management.

What Happened

The manufacturer has expanded its technological capabilities in metal 3D printing, moving beyond traditional production constraints. While specific details about the new technologies or processes have not been fully disclosed, this expansion suggests enhanced production capacity, material versatility, or precision improvements. The company’s strategic move positions it to better serve industries requiring complex metal components with rapid turnaround times.

Why It Matters

This expansion is significant because it directly supports the evolution of distributed manufacturing models. Metal 3D printing enables production closer to the point of use, reducing dependence on centralized factories and complex supply chains. This transformation is critical for digital inventory strategies, where physical stock is minimized by producing parts on demand. The ability to manufacture metal parts additively allows for quicker response to market demands, reduced inventory costs, and customization options previously unattainable with traditional manufacturing.

Technical Context

Metal additive manufacturing typically involves processes such as powder bed fusion, directed energy deposition, or binder jetting. Each technique offers trade-offs between build speed, material properties, and geometric complexity. The manufacturer’s expansion likely involves advances in one or more of these methods, possibly improving print speed, surface finish, or alloy compatibility. These technical improvements are essential to making metal 3D printing commercially viable for broader industrial applications, including aerospace, automotive, and medical sectors.

In distributed manufacturing, digital files replace physical inventory, enabling local facilities or even mobile units to produce parts as needed. Metal 3D printing’s complexity and cost have historically limited this model’s applicability for metal components. However, technological enhancements can lower barriers, making distributed production of critical metal parts more feasible.

Near-term Prediction Model

Over the next 12 to 24 months, we expect the manufacturer’s expansion to catalyze pilot projects integrating metal 3D printing into distributed manufacturing networks. Adoption will initially focus on high-value, low-volume parts where customization and lead-time reduction justify the premium. As process reliability and speed improve, broader commercial deployment will follow, especially in sectors with complex supply chains vulnerable to disruption.

Challenges remain, including ensuring consistent part quality, certification for safety-critical applications, and cost competitiveness with traditional methods. However, the trajectory points toward gradual but steady integration of metal additive manufacturing into digital inventory and on-demand production frameworks.

What to Watch

- Announcements of partnerships or pilot programs utilizing the expanded metal 3D printing capabilities in distributed manufacturing settings.

- Technological breakthroughs that reduce print times and improve material properties for metal parts.

- Regulatory developments addressing certification and standardization of additively manufactured metal components.

- Market responses from industries with critical supply chain needs, such as aerospace and defense.

- Emergence of digital inventory platforms that incorporate metal 3D printing as a core fulfillment strategy.

In summary, the reported expansion by the metal 3D printing manufacturer represents a meaningful step toward realizing the potential of distributed manufacturing and digital inventory. While some details remain unknown, the implications for supply chain resilience, cost efficiency, and customization are profound. Continued monitoring of technological, regulatory, and market developments will be essential to fully understand this evolving landscape.