What Happened

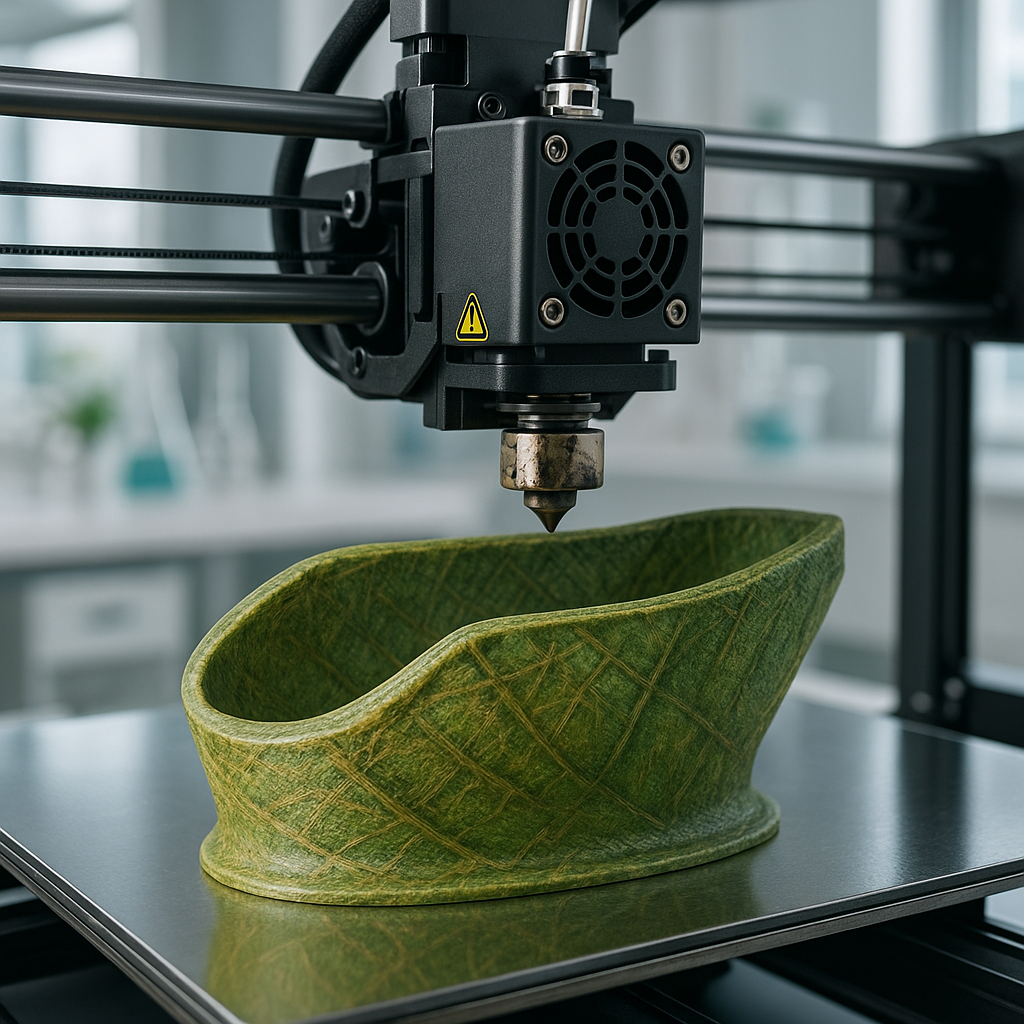

A recent development in 3D printing technology has been reported by CompositesWorld, where a novel 3D printing process has enabled the development of bio-based composite components. This advancement marks a significant step forward in the integration of bio-embedded materials within additive manufacturing, offering a new pathway for creating components that leverage natural, sustainable materials without sacrificing performance.

Why It Matters

The emergence of bio-embedded 3D printing technologies is crucial in the context of growing environmental concerns and demand for sustainable manufacturing. By utilizing bio-based composites, this new process potentially reduces reliance on petroleum-derived plastics and synthetic fibers, which are common in traditional 3D printing materials. This shift not only aligns with global sustainability goals but also opens opportunities for industries such as automotive, aerospace, and consumer goods to adopt greener manufacturing practices.

Moreover, embedding biological elements or bio-based materials directly into 3D printed components can enhance functional properties such as biodegradability, biocompatibility, and even enable smart behavior through responsive materials. This could lead to innovations in medical implants, wearable technology, and environmentally adaptive devices.

Technical Context

While the exact technical details of the new 3D printing process remain sparse in the public domain, the reported advancement involves the fabrication of composite components made from bio-based constituents. Composite materials typically combine two or more distinct materials to achieve superior mechanical or functional properties. In this case, the bio-based composites may integrate natural fibers, bio-polymers, or other biologically derived substances as reinforcement or matrix phases.

The process likely involves modifications to existing additive manufacturing techniques—such as fused filament fabrication (FFF), selective laser sintering (SLS), or stereolithography (SLA)—to accommodate the unique properties of bio-based feedstocks. Challenges that must be addressed include maintaining material homogeneity, ensuring proper bonding between bio-based fibers and polymer matrices, and controlling moisture sensitivity, which is common in biological materials.

Additionally, the process must balance printability with the mechanical and functional properties of the final parts, which is a complex task given the variability and sensitivity of biological materials. Achieving reproducibility and scalability are key hurdles still to be fully overcome.

Near-Term Prediction Model

This innovation can be classified as being in the Pilot stage of maturity, as it represents a novel process with demonstrated feasibility but limited publicly available data on commercial deployment. Given the current state of bio-based composite research and additive manufacturing trends, widespread adoption of such bio-embedded components is likely within 24 to 36 months.

The impact score is estimated at 75 out of 100, reflecting strong potential to influence sustainable manufacturing and smart material applications, tempered by uncertainties in scalability and material performance consistency. Confidence in this prediction stands at 65 out of 100, due to limited technical disclosures and unknowns about integration into existing manufacturing ecosystems.

What to Watch

- Publication of detailed technical papers or patents outlining the specific bio-based materials and printing methods used.

- Demonstrations of mechanical performance benchmarks and long-term durability of bio-based composite components.

- Partnerships between material suppliers, 3D printer manufacturers, and end-user industries to pilot or commercialize the technology.

- Regulatory developments concerning bio-based materials, especially for medical or consumer applications where biocompatibility and safety are critical.

- Advances in hybrid printing techniques that combine bio-embedded materials with conventional polymers or electronics to create multifunctional smart devices.

In summary, this novel 3D printing process for bio-based composite components represents a promising frontier in smart and bio-embedded materials. While many technical and commercial questions remain, the trajectory points toward a more sustainable and functionally advanced future for additive manufacturing.