According to a recent MarketsandMarkets report, the global 3D printing industry is projected to reach a valuation of $35.79 billion by 2030. While much of the market growth is driven by traditional layer-by-layer additive manufacturing methods, an under-covered yet promising technology known as volumetric 3D printing is poised to disrupt the sector with its unique capabilities.

What Happened

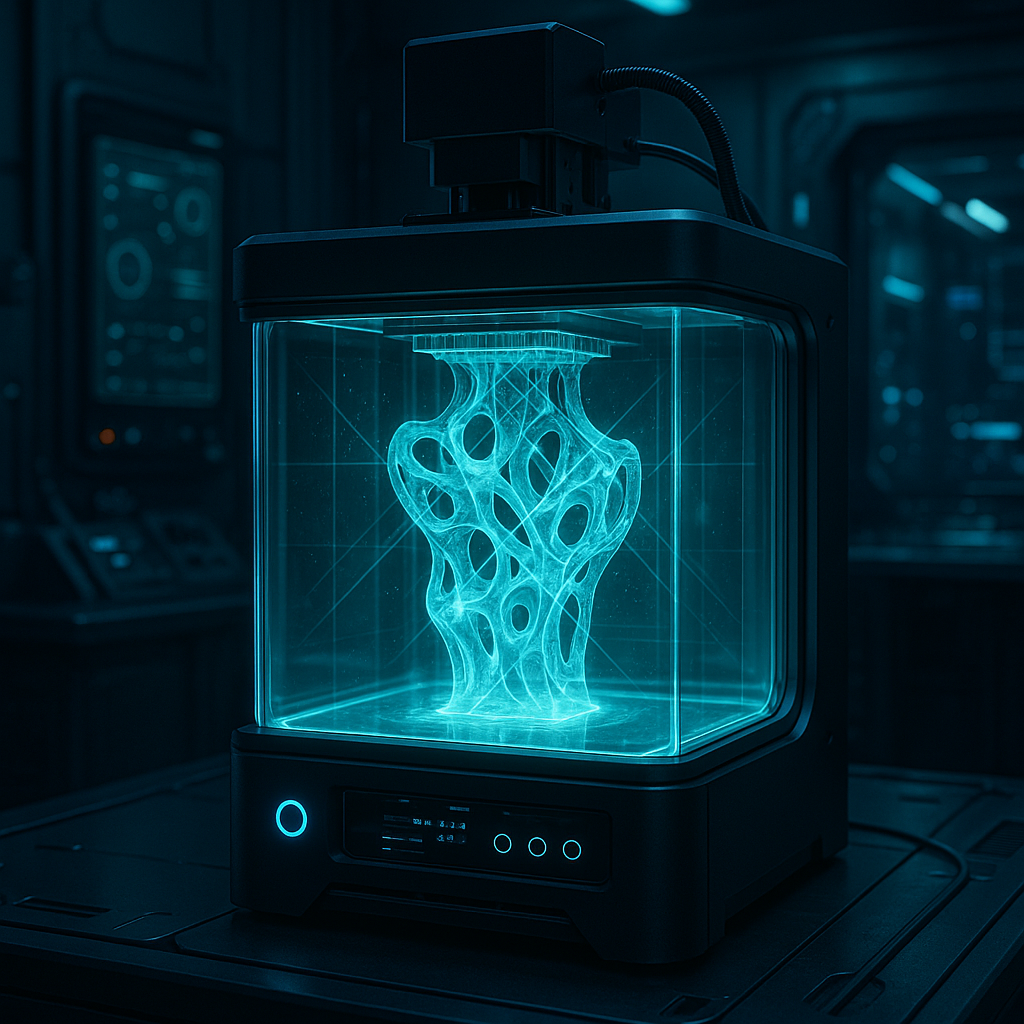

The 3D printing industry continues to expand rapidly, fueled by innovations in materials, hardware, and software. Volumetric 3D printing, which builds objects in a single step by projecting light patterns into a photosensitive resin volume, has gained attention for its potential to overcome speed and complexity limitations inherent to conventional 3D printing. Despite limited mainstream coverage, volumetric 3D printing is advancing through research and pilot-phase commercialization, aligning with the broader industry’s growth trajectory described in the MarketsandMarkets forecast.

Why It Matters

Volumetric 3D printing offers transformative advantages that could redefine manufacturing and prototyping. Unlike traditional 3D printing methods that create parts layer-by-layer, volumetric printing cures an entire 3D object simultaneously within a resin bath, drastically reducing print times from hours to minutes or even seconds. This speed advantage can accelerate product development cycles and enable new applications requiring complex geometries or delicate internal structures that are difficult or impossible to fabricate with standard methods.

Moreover, volumetric printing’s approach reduces mechanical stresses and anisotropy issues common in layered prints, potentially improving the mechanical properties and surface finish of printed parts. These benefits could open doors in industries such as biomedical devices, microfluidics, and aerospace components where precision and material performance are critical.

Technical Context

Volumetric 3D printing typically employs tomographic reconstruction techniques, where multiple 2D light projections are rotated around a resin-filled volume to polymerize the desired 3D shape in a single step. This contrasts with stereolithography (SLA) or digital light processing (DLP), which build objects slice-by-slice.

Key technical challenges remain, including controlling light dose distribution to ensure accurate curing, developing resins with appropriate optical and mechanical properties, and scaling the technology for larger build volumes. Current systems are mostly limited to small parts due to optical penetration depths and resin characteristics. Additionally, post-processing steps such as cleaning and curing still add time to the overall workflow.

Near-Term Prediction Model

Volumetric 3D printing is currently in a pilot to early commercial stage. Over the next 24 to 36 months, we expect incremental improvements in hardware precision, resin formulations, and software algorithms to enhance print resolution and part size. Adoption will likely begin in niche sectors where speed and complex geometries are paramount, such as biomedical research and microfabrication.

Mass-market penetration remains uncertain due to cost, material limitations, and integration challenges with existing manufacturing workflows. However, as the broader 3D printing market approaches $35.79 billion by 2030, volumetric printing could capture a meaningful share by offering complementary capabilities rather than replacing established methods.

What to Watch

- Advances in resin chemistry to improve optical clarity, cure speed, and mechanical properties.

- Development of larger-scale volumetric printers capable of producing bigger parts without sacrificing resolution.

- Integration of volumetric printing with hybrid manufacturing systems combining additive and subtractive techniques.

- Emergence of new applications uniquely enabled by volumetric printing’s speed and complexity advantages.

- Intellectual property activity and partnerships between volumetric printing startups and established 3D printing companies.

While volumetric 3D printing remains a frontier technology, its potential to accelerate and diversify additive manufacturing is significant. Continued R&D, coupled with market growth highlighted in the MarketsandMarkets report, suggests volumetric printing could become a vital pillar of the additive manufacturing ecosystem by the end of this decade.