What Happened

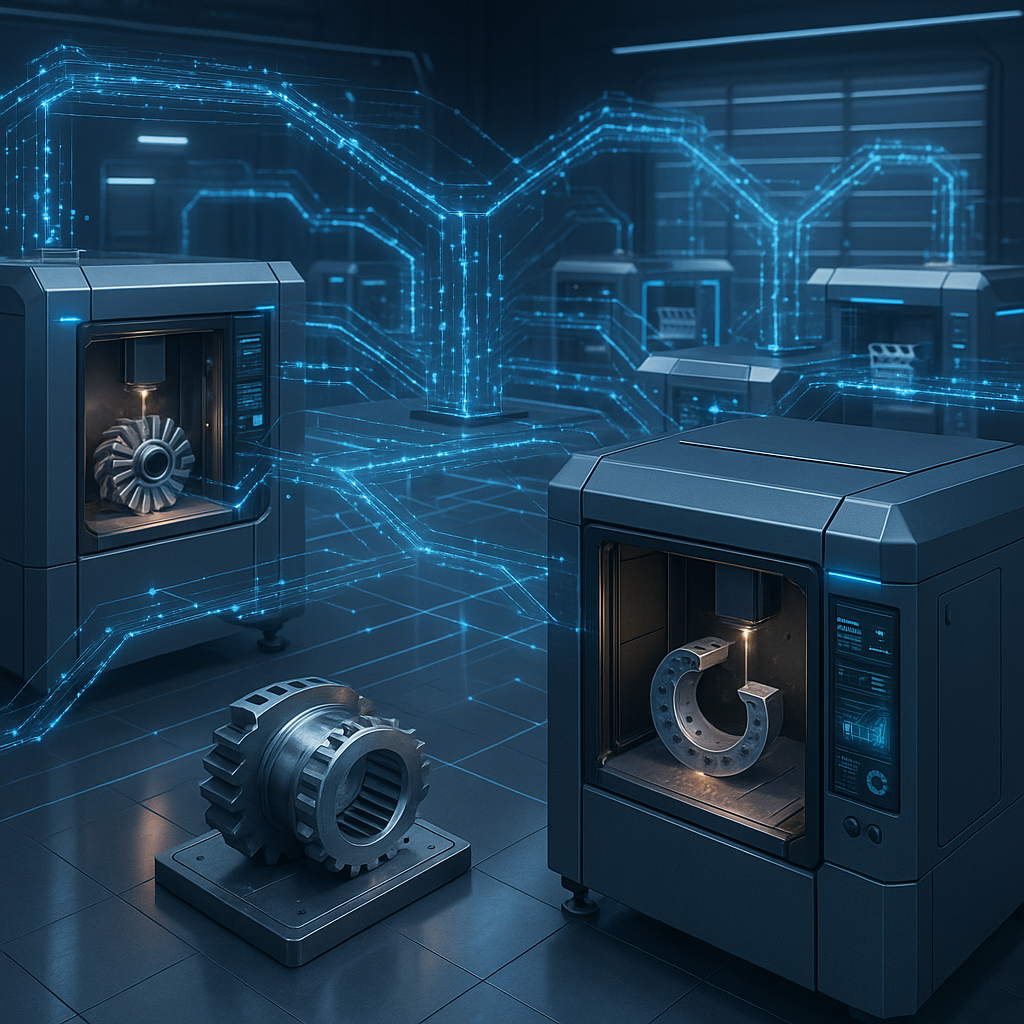

According to a recent article from The News Journal, a leading metal 3D printing manufacturer has recently expanded its technological capabilities. This development marks a significant step forward in advanced manufacturing, particularly in metal additive manufacturing, which is increasingly integral to distributed manufacturing and digital inventory strategies.

Why It Matters

This expansion is not just a company milestone but a signal of broader trends transforming supply chains and production models. Metal 3D printing’s enhanced capabilities enable on-demand production closer to the point of use, reducing reliance on centralized inventories and lengthy logistics. This shift supports the rise of distributed manufacturing, where digital inventory files replace physical stock, and parts are printed locally as needed.

Such a model offers agility and responsiveness, crucial in sectors like aerospace, automotive, and defense, where part availability and customization are critical. It also promises environmental benefits by cutting transportation emissions and reducing waste through precise additive processes.

Technical Context

Metal 3D printing technologies, such as selective laser melting (SLM) and electron beam melting (EBM), have matured significantly, but challenges remain in speed, material properties, and scale. The manufacturer’s recent advancements likely address these areas, improving throughput and the range of printable alloys, though specific technical details are not disclosed in the source.

Integrating these improvements into distributed manufacturing requires robust digital workflows, including secure digital inventory management, standardized design files, and quality assurance protocols to ensure consistent part performance across decentralized sites.

Near-term Prediction Model

Over the next 12 to 24 months, the expanded metal 3D printing capabilities are expected to accelerate adoption of distributed manufacturing models in industries with complex supply chains. Early adopters will likely focus on high-value, low-volume parts where customization and rapid turnaround are advantageous.

However, widespread deployment depends on overcoming remaining technical and operational hurdles, such as certification standards for printed metal parts and integration with existing manufacturing systems.

What to Watch

- Announcements of new partnerships or pilot projects leveraging the expanded metal 3D printing technology for distributed manufacturing applications.

- Development of industry standards and certification frameworks for metal additive manufacturing in critical sectors.

- Advances in digital inventory platforms that enable secure, efficient file distribution and production tracking across multiple sites.

- Material science breakthroughs that expand the range of alloys suitable for additive processes while enhancing mechanical properties.

- Regulatory changes or incentives supporting localized, on-demand manufacturing to reduce supply chain vulnerabilities.

While the source article highlights the technological expansion, details such as the specific new capabilities, targeted industries, and deployment timelines remain undisclosed. Continued monitoring of industry announcements and pilot outcomes will provide clearer insights into the impact of these advancements.