In a significant move for the additive manufacturing sector, ASTM International has announced a collaboration with the UK Ministry of Defence (MoD) on a project under America Makes, the United States’ national additive manufacturing innovation institute. This partnership aims to leverage distributed manufacturing and digital inventory concepts to enhance supply chain resilience and agility, particularly in defense applications.

What Happened

ASTM International, a globally recognized standards organization, is working alongside the UK MoD as part of an America Makes initiative. The project focuses on developing standards and frameworks that enable efficient distributed manufacturing networks supported by digital inventory systems. While details remain limited, the collaboration signals a strategic alignment between US and UK defense sectors to adopt additive manufacturing technologies more deeply, particularly in contexts requiring rapid, on-demand production of parts and components.

Why It Matters

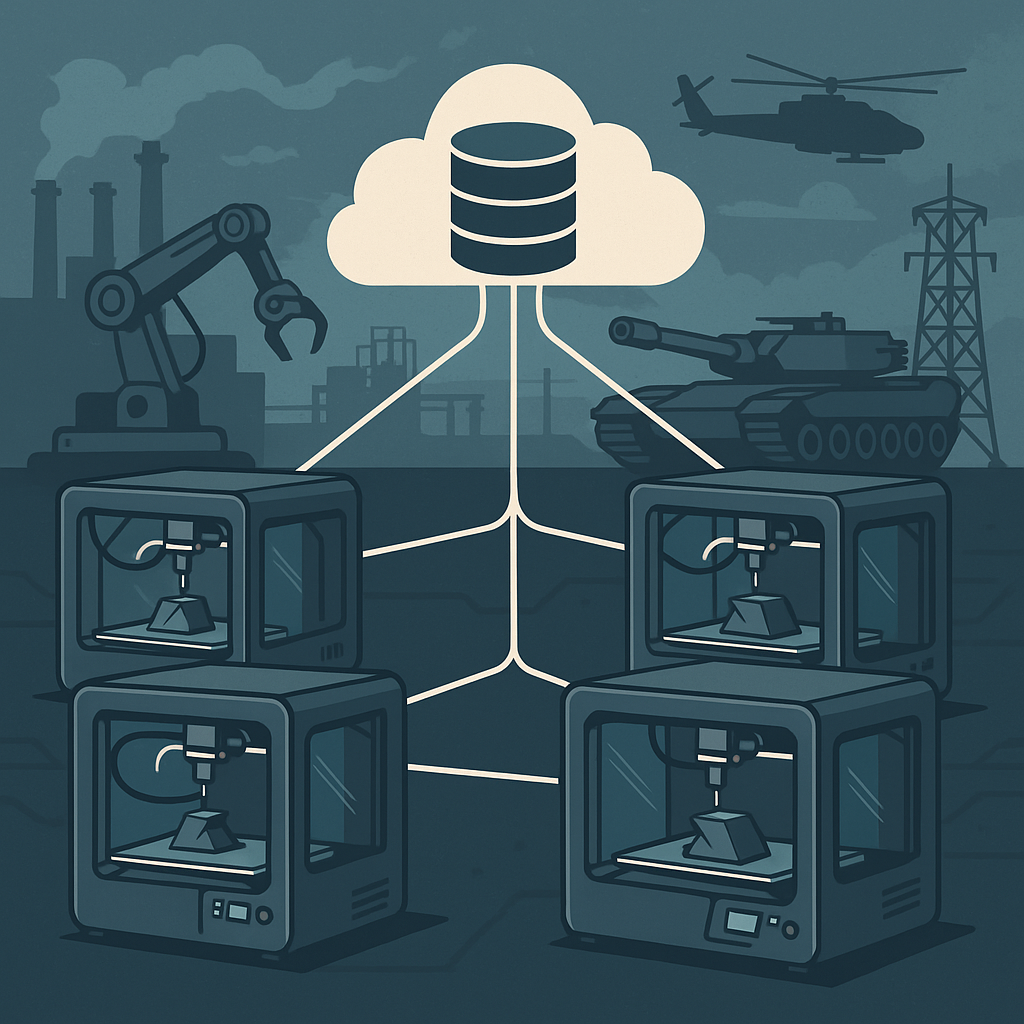

This partnership underscores the growing importance of distributed manufacturing within defense supply chains. Traditional manufacturing and inventory models rely on centralized production and large physical stockpiles, which can be vulnerable to disruption. By contrast, digital inventory combined with distributed manufacturing allows for digital files of parts to be stored and securely transmitted to geographically dispersed 3D printing facilities, enabling rapid local production as needed.

For defense organizations, this capability translates into enhanced readiness, reduced logistics burdens, and the ability to respond swiftly to emergent operational needs. The collaboration between ASTM International and the UK MoD within the America Makes framework also suggests a concerted effort to establish interoperable standards that can facilitate cross-national cooperation and technology sharing in additive manufacturing.

Technical Context

Distributed manufacturing in the context of 3D printing involves a network of production nodes capable of fabricating parts on-demand based on digital designs. Digital inventory refers to the secure storage and management of these design files, often incorporating encryption and blockchain technologies to ensure authenticity and traceability.

Standards development is critical to this ecosystem, addressing challenges such as part qualification, data security, interoperability of machines and software, and quality assurance across distributed sites. ASTM International has been at the forefront of developing additive manufacturing standards, and this project likely aims to extend those efforts to cover the unique requirements of distributed manufacturing for defense use.

Key technical challenges include ensuring consistent part quality across diverse printing locations, managing intellectual property rights for digital assets, and integrating digital inventory systems with existing logistics and supply chain infrastructures.

Near-term Prediction Model

Given the maturity of additive manufacturing technologies and the strategic interest from defense agencies, this project is expected to progress from pilot phases into early commercial deployments within the next 12 to 24 months. Initial applications will likely focus on non-critical or legacy parts, where rapid prototyping and supply chain resilience offer immediate benefits without compromising operational safety.

As standards and frameworks mature, broader adoption could follow, potentially transforming how military logistics and maintenance are conducted. However, widespread implementation will depend on overcoming technical, regulatory, and cybersecurity challenges inherent in distributed manufacturing networks.

What to Watch

- Publication of new ASTM standards specifically addressing distributed manufacturing and digital inventory security.

- Demonstrations or pilot programs by the UK MoD and America Makes showcasing on-demand production capabilities in operational environments.

- Advancements in digital rights management and blockchain integration for secure handling of digital inventory files.

- Collaborations or partnerships expanding beyond the UK and US, indicating international adoption of interoperable distributed manufacturing standards.

- Development of certification processes to ensure consistent quality and safety of parts produced across distributed networks.

While many specifics remain undisclosed, this collaboration marks a pivotal step toward integrating distributed manufacturing into critical defense supply chains, potentially reshaping logistics and inventory management paradigms in the near future.