What Happened

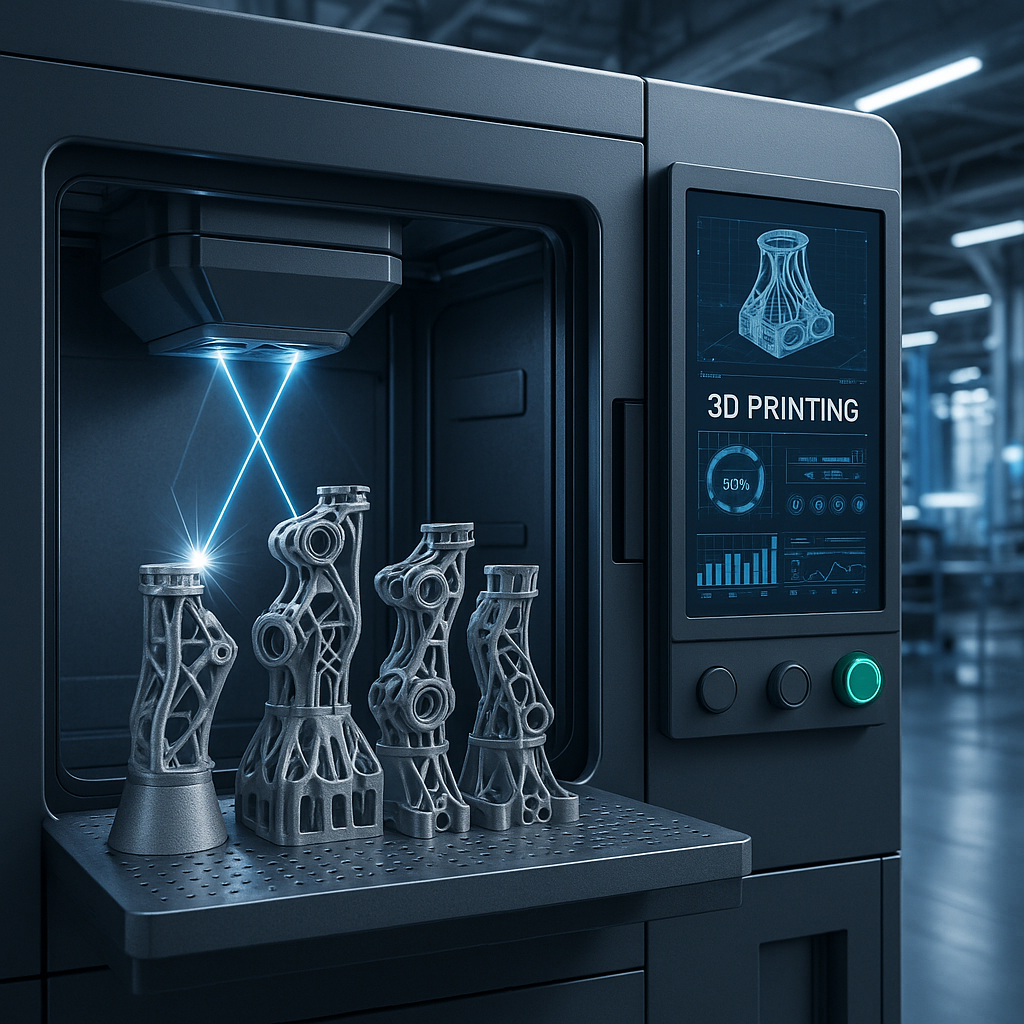

IN3DTEC has launched a comprehensive metal 3D printing service promising up to 80% cost savings and a rapid 3-day turnaround, according to a recent report by 3D Printing Industry. This service targets industrial clients needing metal parts with fast turnaround and cost efficiency, positioning itself as a game changer for on-demand spares and digital inventory management.

Why It Matters

The ability to produce metal components quickly and affordably addresses a critical bottleneck in supply chains, especially for spare parts. Traditional manufacturing often involves long lead times and high inventory costs. IN3DTEC’s solution enables companies to reduce physical stock and produce parts only when needed, slashing storage costs and mitigating risks of obsolescence. This aligns with the growing trend of digital inventory and on-demand manufacturing, which promises greater operational agility and resilience.

Technical Context

Metal 3D printing technologies, such as selective laser melting (SLM) and direct metal laser sintering (DMLS), have matured significantly but still face challenges including high costs, limited throughput, and post-processing requirements. IN3DTEC’s service claims to overcome some of these barriers by optimizing the entire workflow—from design to finished part—allowing for significant cost reductions and a 3-day turnaround. However, specific technical details such as the range of metals supported, part size limitations, and surface finish quality remain undisclosed in the source.

The integration of digital inventory systems with such on-demand manufacturing services is critical. It requires seamless digital part libraries, advanced design-for-additive-manufacturing (DfAM) capabilities, and robust quality assurance processes. While IN3DTEC’s offering addresses the manufacturing speed and cost, the broader ecosystem readiness—including digital catalog management and supply chain integration—is a factor that will influence adoption.

Near-term Prediction Model

Given the commercial availability of IN3DTEC’s service and its promising performance metrics, adoption in sectors with high-value metal spare parts is expected to accelerate within 12 to 18 months. Early adopters will likely be industries such as aerospace, automotive, and heavy machinery maintenance, where downtime costs are significant and part customization is common. The cost savings and speed advantage will drive pilot projects evolving into scaled deployments.

However, the full transition from traditional inventory to digital on-demand spares will depend on overcoming challenges related to certification, part qualification, and integration with existing supply chains. The service’s impact score is high due to the potential disruption in spare parts logistics, but confidence is moderate until more detailed performance data and case studies emerge.

What to Watch

- Expansion of IN3DTEC’s metal material portfolio and part size capabilities.

- Development of digital inventory management platforms that integrate directly with IN3DTEC’s service.

- Case studies demonstrating reliability, repeatability, and certification of printed metal spares in critical industries.

- Competitive responses from traditional manufacturing and other metal 3D printing service providers.

- Regulatory and quality assurance frameworks adapting to on-demand metal part production.

In summary, IN3DTEC’s metal 3D printing service offers a tangible leap forward in enabling cost-effective, rapid production of on-demand spares. This development exemplifies the shift toward digital inventory and on-demand manufacturing, promising to reshape spare parts supply chains and reduce operational costs across multiple industries.