The 3D printing landscape is rapidly evolving, with an emerging focus on multi-axis additive manufacturing that transcends traditional planar layering. According to the recent StartUs Insights article on 20 Top 3D Printing Startups to Watch in 2025, a number of innovative startups are pioneering technologies that enable printing on multiple axes, moving beyond the traditional XY plane with vertical Z layering.

What Happened

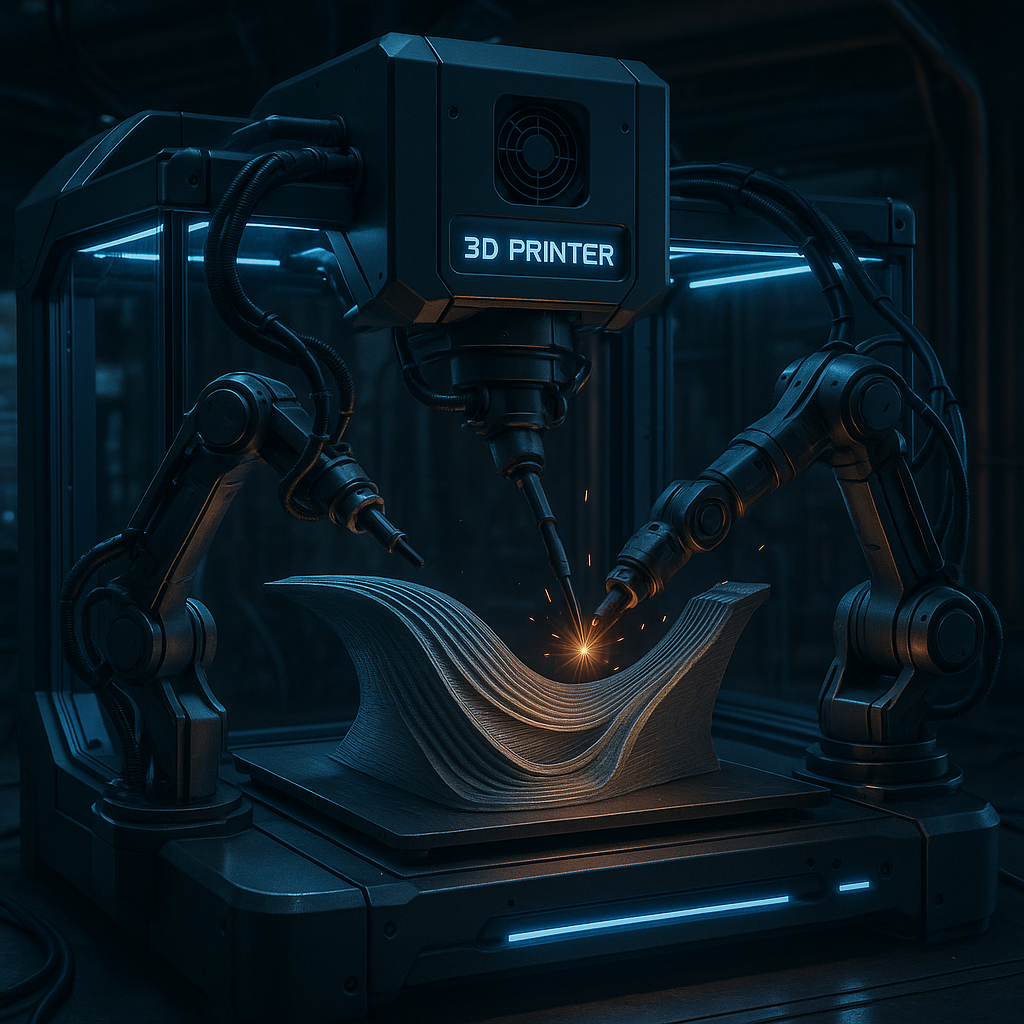

Startups highlighted in the 2025 list are pushing the boundaries of additive manufacturing by developing hardware and software solutions that incorporate multi-axis motion systems. These systems allow print heads or build platforms to rotate and tilt, enabling deposition of material on curved or angled surfaces in a continuous, non-planar fashion. This breakthrough approach is a significant departure from conventional 3D printers that build parts layer by layer in strictly horizontal slices.

While the article does not detail specific company names or proprietary technologies, it signals a clear industry trend: the maturation and commercialization of multi-axis additive manufacturing as a viable production method.

Why It Matters

Multi-axis additive manufacturing addresses several critical limitations of traditional 3D printing:

- Improved Mechanical Properties: By printing along curved paths and varying layer orientations, parts can achieve superior strength and durability through optimized fiber alignment and reduced anisotropy.

- Complex Geometry Realization: Overhangs, undercuts, and intricate internal features can be printed without support structures, reducing material waste and post-processing.

- Surface Finish and Precision: Non-planar layering can produce smoother surfaces and finer detail by conforming deposition to the part’s geometry rather than slicing it into flat layers.

These advantages open new applications in aerospace, automotive, medical implants, and tooling where performance and complexity are paramount.

Technical Context

Multi-axis additive manufacturing integrates advanced robotics and motion control with additive processes such as fused filament fabrication (FFF), directed energy deposition, or material jetting. The key technical challenges include:

- Motion Coordination: Synchronizing multiple rotational and translational axes to maintain precise nozzle positioning and consistent material flow.

- Toolpath Generation: Developing sophisticated slicing algorithms and non-planar toolpaths that adapt to complex geometries while optimizing print speed and quality.

- Material Behavior: Understanding how materials cure or solidify when deposited on angled surfaces and ensuring interlayer adhesion.

Current research and pilot projects focus on refining these aspects to achieve reliable, repeatable production capabilities.

Near-Term Prediction Model

Over the next 12 to 24 months, we anticipate the following trajectory for multi-axis additive manufacturing:

- Maturity Stage: Transitioning from pilot to early commercial deployment as startups validate their systems in niche markets.

- Adoption Drivers: Demand for lightweight, high-strength components with complex geometries will accelerate uptake, especially in aerospace and medical sectors.

- Technology Evolution: Improvements in motion control, software toolchains, and material formulations will enhance print quality and process robustness.

- Barriers: High capital costs, complexity of operation, and limited material options may slow widespread adoption.

What to Watch

- Emerging Startups: Identify companies offering turnkey multi-axis 3D printing solutions and their targeted applications.

- Software Innovations: Advances in non-planar slicing algorithms and AI-driven toolpath optimization.

- Material Development: New composites or polymers engineered for multi-axis deposition and adhesion.

- Industry Collaborations: Partnerships between startups, OEMs, and end-users to co-develop application-specific platforms.

- Standardization Efforts: Progress toward establishing process and quality standards for multi-axis additive manufacturing.

In conclusion, the spotlight on multi-axis additive manufacturing startups in 2025 underscores a pivotal shift in 3D printing technology. While still emerging, this approach promises to expand the design freedom, functional performance, and industrial relevance of additive manufacturing. Continuous monitoring of technical breakthroughs and market adoption will be crucial for stakeholders aiming to leverage this frontier technology.