In a notable development covered by the Detroit Free Press, a leading metal 3D printing manufacturer has expanded its technological capabilities, signaling a shift that could significantly impact distributed manufacturing and digital inventory management.

What Happened

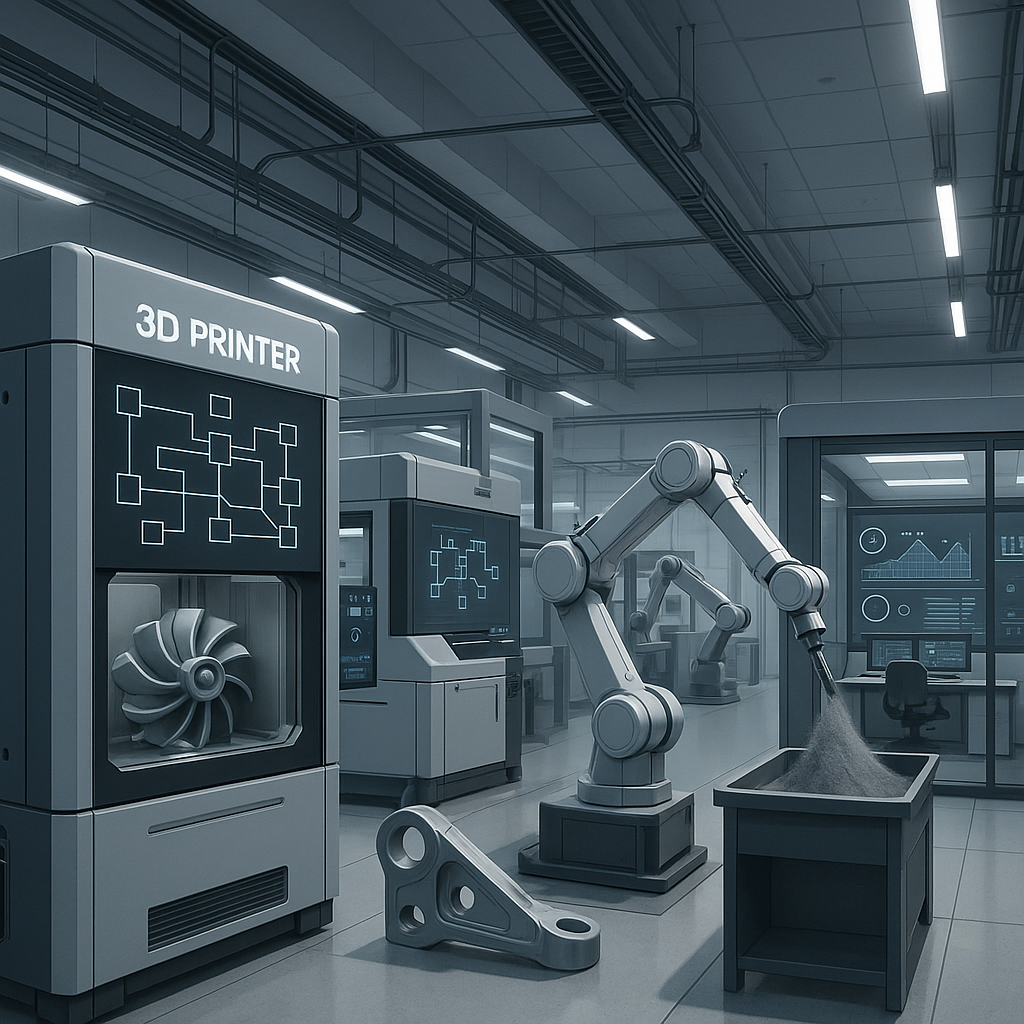

The manufacturer, whose name and specific technologies remain undisclosed in the article, has broadened its reach in metal additive manufacturing. This expansion likely involves enhancements in machine performance, material options, and software integration, though exact details are not fully disclosed. The move indicates a strategic push to leverage metal 3D printing for more flexible, on-demand production models.

Why It Matters

Metal 3D printing is a cornerstone technology for enabling distributed manufacturing — a production paradigm where manufacturing capabilities are decentralized and located closer to end-users or demand points. By expanding its technological reach, this manufacturer is positioning itself to better support digital inventory and on-demand manufacturing strategies. This can reduce reliance on large, centralized warehouses by enabling parts and components to be printed as needed, closer to the point of use.

Such capabilities are transformative for industries like aerospace, automotive, and defense, where complex metal parts are critical and supply chain disruptions can be costly. Digital inventory reduces inventory holding costs and mitigates risks associated with overproduction or obsolescence.

Technical Context

Metal 3D printing, or metal additive manufacturing, uses techniques such as selective laser melting (SLM), electron beam melting (EBM), and direct energy deposition (DED) to build parts layer-by-layer from metal powders or wires. Advancements often focus on improving build speed, part quality, material properties, and post-processing efficiency.

The expansion referenced likely includes improvements in one or more of these areas. For example, enhanced laser control, better powder handling, or integration with advanced software platforms for digital inventory management and production scheduling could be part of the new capabilities. These advances help bridge the gap between prototyping and full-scale production, making metal 3D printing more viable for on-demand manufacturing.

Near-term Prediction Model

Over the next 12 to 24 months, expect to see increased adoption of metal 3D printing solutions tailored for distributed manufacturing networks. Manufacturers will increasingly integrate these technologies into digital inventory systems, enabling real-time production of spare parts and custom components on demand.

Challenges remain, including ensuring consistent part quality across distributed sites, managing intellectual property and data security for digital inventory files, and scaling production speeds to meet industrial demand. However, continuous technological improvements and growing industry acceptance will drive steady progress.

What to Watch

- Announcements from metal 3D printing firms regarding new machine capabilities, materials, or software that support distributed manufacturing.

- Case studies or pilot programs deploying metal additive manufacturing within digital inventory frameworks across sectors such as aerospace or automotive.

- Development of standards and certifications for quality assurance in distributed metal 3D printing production.

- Collaborations between manufacturers, software providers, and supply chain partners to create integrated on-demand manufacturing ecosystems.

- Regulatory and intellectual property policies impacting digital inventory and distributed manufacturing models.

While specifics about this manufacturer’s new technologies are limited, the reported expansion underscores the growing role of metal 3D printing in reshaping manufacturing supply chains toward more agile, digital, and distributed paradigms.