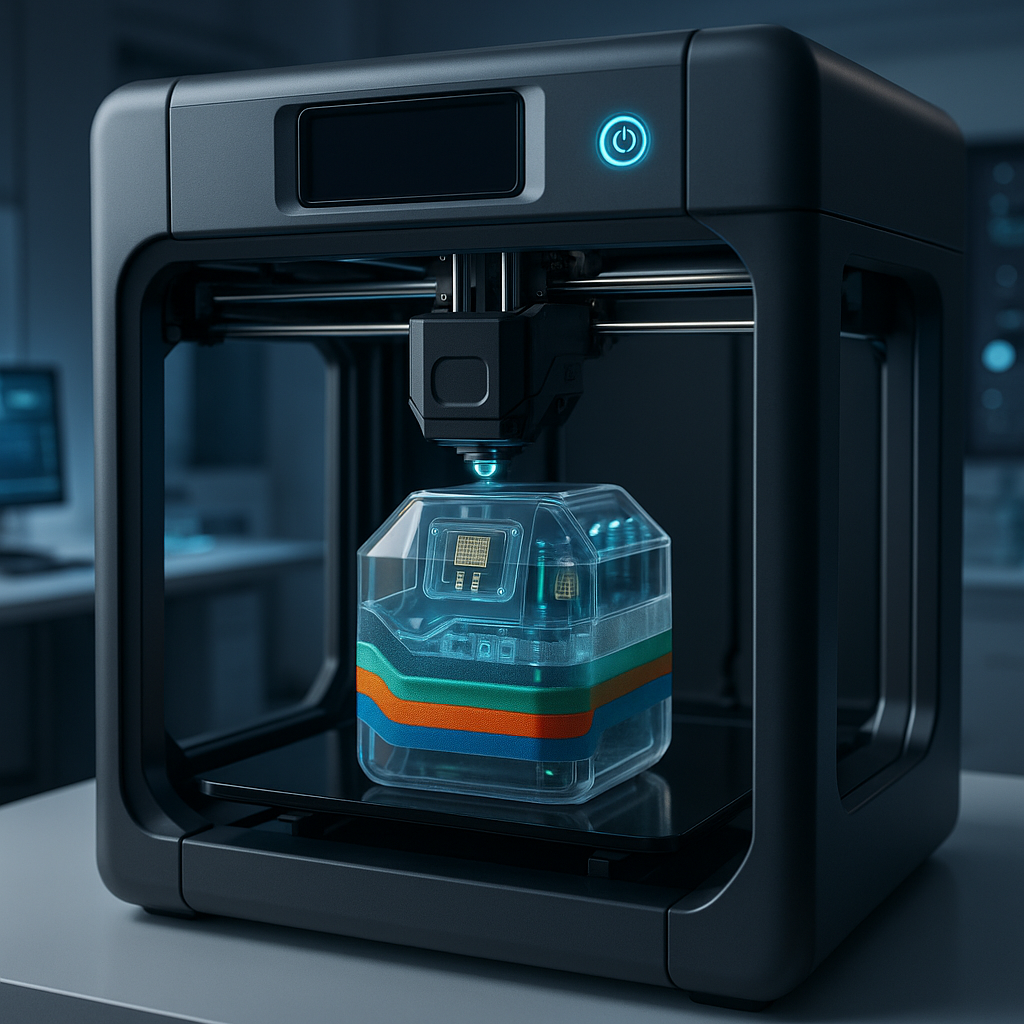

In a significant development for the field of 3D printing, a novel technique that streamlines multi-material prototyping has been reported, promising to accelerate the integration of embedded sensors within smart and bio-embedded materials. This advancement, detailed in a recent Photonics Spectra article from October 2024, marks a pivotal step toward more efficient, flexible manufacturing of complex prototypes that embed sensing capabilities directly into the material matrix.

What Happened

The reported 3D-printing technique enables the simultaneous fabrication of multiple materials within a single build process, allowing for the seamless embedding of sensors into prototypes without the need for subsequent assembly or post-processing. While the article does not specify the exact materials or sensor types used, the implication is that this approach can integrate functional elements such as pressure, temperature, or strain sensors directly within structural components during printing.

This multi-material strategy simplifies prototyping workflows by reducing complexity, time, and potential points of failure associated with manually embedding sensors after printing. The technology appears to leverage advances in printer hardware and material science to precisely deposit diverse materials with compatible interfaces, ensuring sensor functionality and structural integrity.

Why It Matters

The ability to embed sensors directly during 3D printing is transformative for the development of smart and bio-embedded materials. These materials are increasingly important in applications ranging from wearable health monitors and biofeedback devices to adaptive robotics and aerospace components with real-time condition monitoring.

Traditional prototyping methods often require separate sensor placement and complex wiring, limiting design flexibility and increasing manufacturing costs. By streamlining multi-material printing with embedded sensors, designers and engineers can rapidly iterate on intelligent devices that are lighter, more compact, and better integrated.

This breakthrough also has implications for bio-embedded systems, where sensors must be biocompatible and embedded within soft or flexible matrices. The technique could enable new classes of medical implants or tissue engineering scaffolds that monitor physiological parameters in situ, enhancing patient outcomes and personalized medicine.

Technical Context

Multi-material 3D printing has been an area of active research but faces challenges such as material compatibility, interfacial adhesion, and the preservation of sensor function during the printing process. Embedding sensors requires precise control over deposition parameters and material properties to avoid damage to delicate sensing elements.

The reported technique likely involves advanced printer architectures capable of handling multiple printheads or material delivery systems, coupled with software that orchestrates the complex print paths for different materials. The materials themselves must be engineered to maintain electrical conductivity, flexibility, or biocompatibility as needed, depending on sensor type and application.

However, specific technical details such as the types of sensors integrated, the materials used, or the resolution and scale of printing remain undisclosed in the source. This gap limits a full understanding but highlights the novelty and potential of the approach.

Near-Term Prediction Model

Given the current status, this multi-material 3D-printing technique with embedded sensors is likely in the pilot stage, transitioning from research prototypes toward commercial viability within the next 12 to 24 months. Early adopters in aerospace, healthcare, and wearable technology sectors may begin integrating this approach to accelerate product development cycles.

Impact is expected to be moderate to high (impact score ~75) due to the broad applicability and the growing demand for smart materials. Confidence in this prediction is moderate (~65) given the limited technical disclosure and the inherent challenges in scaling multi-material sensor integration.

What to Watch

- Publication of detailed technical specifications and case studies demonstrating sensor types, material compatibility, and performance metrics.

- Commercial announcements from 3D printer manufacturers adopting or licensing this multi-material embedded sensor technology.

- Regulatory developments affecting bio-embedded sensor devices, which could influence adoption timelines in medical applications.

- Emerging partnerships between material scientists, sensor manufacturers, and 3D printing firms focused on integrated smart material solutions.

- Advances in software tools for multi-material print path optimization and sensor calibration during printing.

In conclusion, the technique highlighted by Photonics Spectra points to an exciting evolution in 3D printing, where embedded sensors become integral to prototypes from the outset. This capability promises to accelerate innovation in smart and bio-embedded materials, fostering new applications and enhancing device intelligence across industries.