What Happened

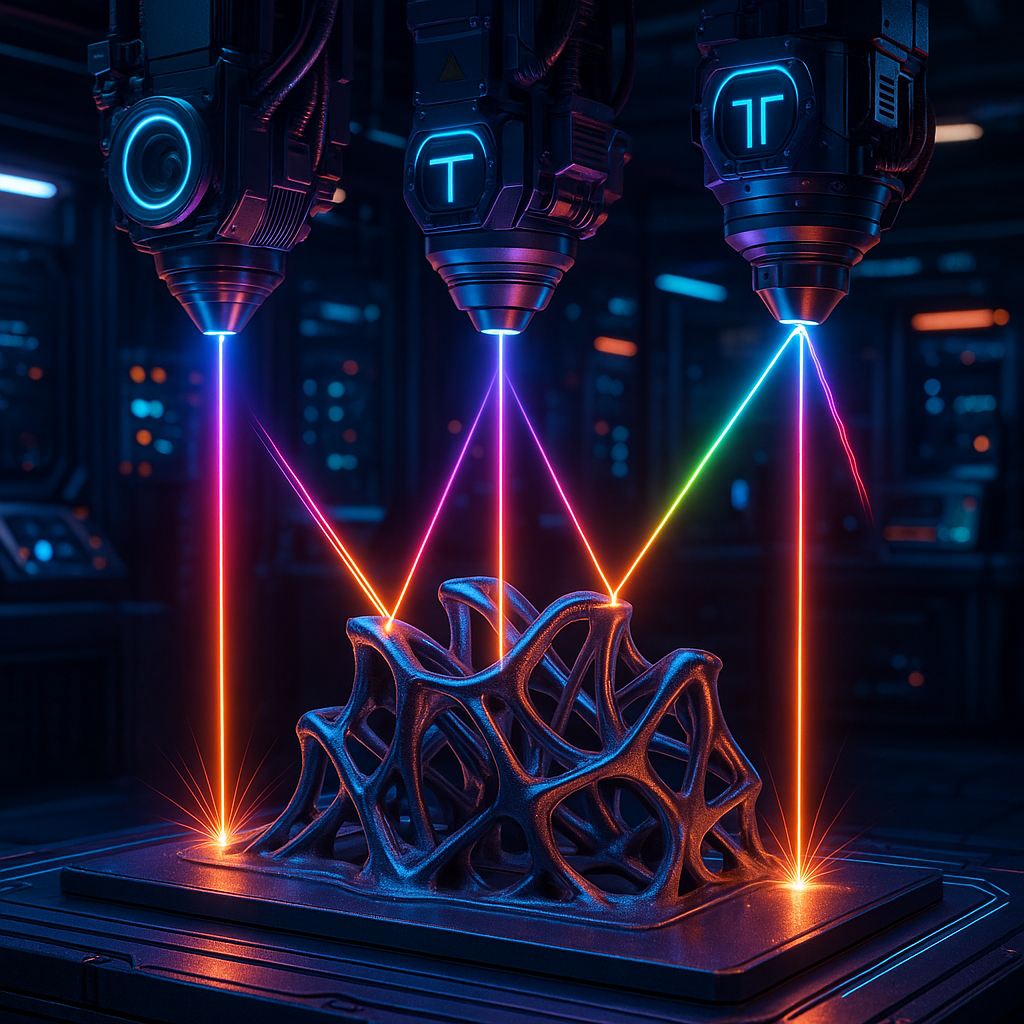

In a recent development reported by Photonics.com in February 2025, a novel beam-shaping method has been introduced that optimizes the 3D printing process. This technological advancement refines how laser beams are manipulated during printing, significantly improving efficiency and precision. While the report primarily focuses on the beam-shaping itself, the implications for collaborative printing and swarm manufacturing are profound, suggesting new pathways for scaling and coordinating multiple print heads or units working in tandem.

Why It Matters

Collaborative printing, often referred to as swarm 3D printing, involves multiple printers or print heads working simultaneously on a single object or a set of objects to accelerate production and improve scalability. The newly developed beam-shaping technique enhances the control over laser energy distribution, which directly impacts print speed, resolution, and material properties. This means that in a collaborative printing environment, where synchronization and uniformity are critical, such beam control can reduce defects and increase throughput.

Moreover, as industries demand faster prototyping and on-demand manufacturing, the ability to orchestrate multiple printers with optimized beam profiles could lead to breakthroughs in large-scale additive manufacturing. This technology could be a key enabler for decentralized manufacturing models, where swarms of smaller printers collectively produce complex parts more efficiently than a single large machine.

Technical Context

Beam-shaping involves modifying the spatial intensity profile of a laser beam to achieve desired effects on the material being processed. Traditional 3D printing lasers often use Gaussian beams, which have peak intensity at the center and taper off towards the edges, potentially causing uneven energy distribution and suboptimal melting or curing.

The new method reported enhances beam uniformity or customizes intensity patterns, allowing better control over the thermal gradients and solidification rates during printing. This is crucial in collaborative printing scenarios where multiple beams may interact or overlap, requiring precise energy management to avoid defects such as warping, incomplete fusion, or residual stresses.

While the exact technical specifications and implementation details of the beam-shaping method remain undisclosed in the source, the advancement likely involves adaptive optics or diffractive optical elements integrated into the laser delivery system. These technologies can dynamically adjust beam profiles in real-time, which is essential for the complex, multi-head coordination in swarm printing setups.

Near-term Prediction Model

Given the current state of beam-shaping R&D and the growing interest in collaborative 3D printing, this innovation is positioned at the Pilot stage. Within the next 12 to 18 months, we can expect prototype systems incorporating advanced beam-shaping to emerge, particularly in research labs and specialized industrial settings focused on swarm manufacturing.

The impact score is estimated at 75, reflecting substantial potential to enhance print quality and speed but tempered by integration challenges and the need for robust control algorithms for multi-unit coordination. Confidence is moderate at 65 due to limited public technical details and the nascent stage of commercial adoption.

What to Watch

- Announcements from leading 3D printer manufacturers regarding integration of beam-shaping optics in multi-head or swarm printing systems.

- Research publications or patents detailing the specific optical technologies enabling dynamic beam profile control.

- Demonstrations of collaborative printing setups that showcase improved throughput and part uniformity enabled by beam-shaping.

- Development of software and control algorithms capable of synchronizing multiple beam-shaped lasers in real time.

- Material science advancements that leverage uniform energy delivery to expand printable materials and improve mechanical properties.

While the beam-shaping innovation marks a significant step forward, its full impact on collaborative 3D printing will depend on successful system-level integration and the evolution of swarm coordination technologies. Continued monitoring of this intersection between photonics and additive manufacturing is essential for stakeholders aiming to capitalize on next-generation swarm printing capabilities.