What Happened

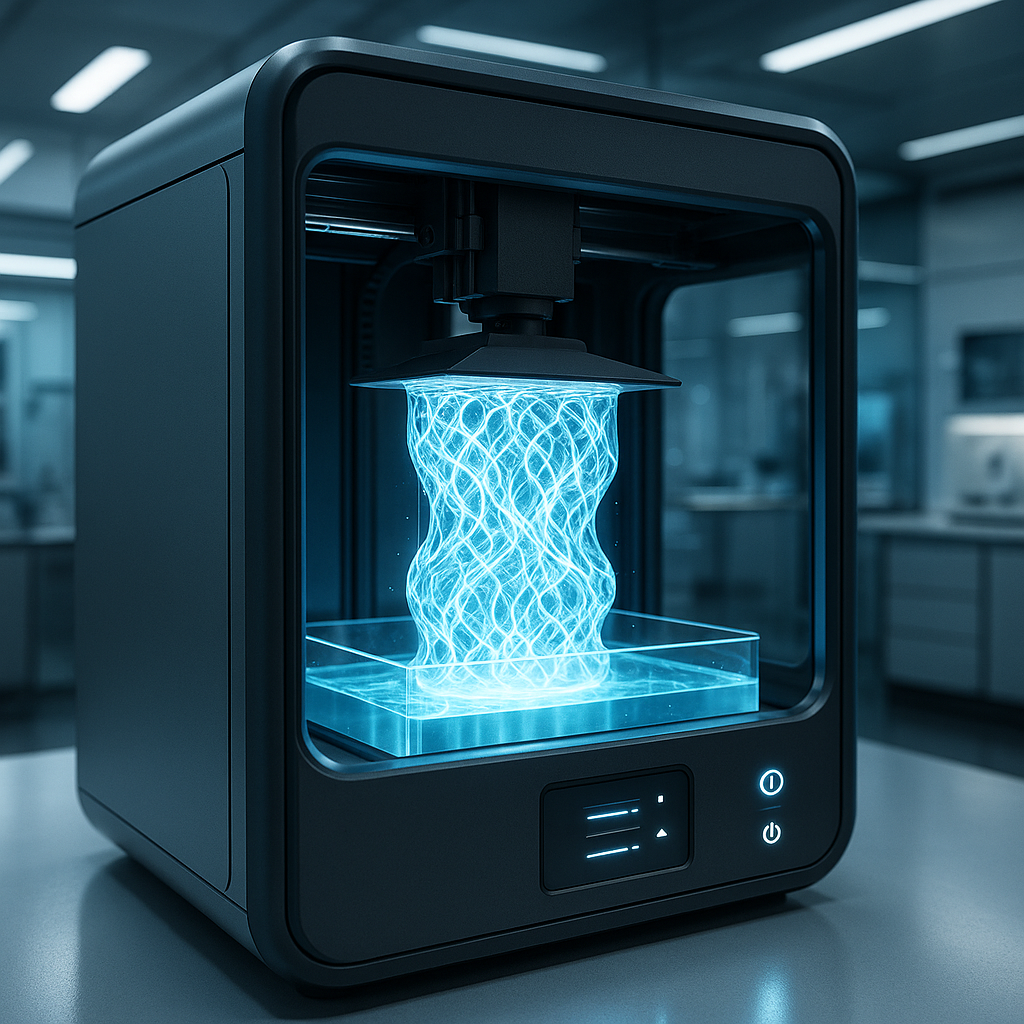

In a remarkable breakthrough reported by Interesting Engineering on February 13, 2026, Chinese researchers have shattered the speed record for 3D printing by fabricating objects in an astonishing 0.6 seconds. This milestone is especially significant because it involves volumetric 3D printing, a cutting-edge technology that constructs entire 3D objects simultaneously rather than layer-by-layer. While the report highlights the speed achievement, many technical details remain undisclosed, leaving room for further scrutiny and validation by the broader 3D printing community.

Why It Matters

The speed of 3D printing has long been a bottleneck limiting its adoption for mass production and time-sensitive applications. Traditional additive manufacturing methods—such as fused deposition modeling (FDM) or stereolithography (SLA)—build parts layer upon layer, resulting in production times ranging from minutes to hours depending on complexity and size. Achieving full object fabrication in under a second represents a paradigm shift that could dramatically expand the use cases for 3D printing.

Volumetric 3D printing’s ability to create entire objects simultaneously can enable rapid prototyping, on-demand manufacturing, and even emergency medical device production in critical situations. The Chinese breakthrough signals that volumetric printing is transitioning from a promising research concept to a viable industrial technology, potentially disrupting supply chains and manufacturing workflows worldwide.

Technical Context

Volumetric 3D printing differs fundamentally from layer-based approaches by using light patterns or other energy sources projected into a photosensitive resin or material volume. By precisely controlling the spatial and temporal distribution of energy, the entire 3D shape can be polymerized or solidified in one step. This approach eliminates the need for supports or slicing, reducing post-processing and enabling complex geometries.

Prior to this achievement, volumetric printing demonstrations typically required several seconds to minutes to complete objects, limited by the resolution and intensity of the light source, material chemistry, and computational modeling of the light paths. The new record of 0.6 seconds suggests substantial advances in optical systems, material formulations with ultra-fast curing kinetics, and real-time volumetric light modulation technologies.

However, the report does not specify the size, resolution, or mechanical properties of the printed objects, which are critical factors for assessing practical applications. It also remains unclear whether the method is scalable to larger parts or diverse materials beyond photopolymers.

Near-term Prediction Model

Given the current state of volumetric 3D printing and this new speed record, the technology is likely in a late R&D to Pilot stage with commercial deployment expected within 12 to 24 months for niche applications. Early adopters may include biomedical device manufacturers, rapid prototyping services, and specialty component producers who prioritize speed over material diversity or size constraints.

As research continues to optimize resin chemistries, optical hardware, and software control, we can expect incremental improvements in resolution, part size, and material compatibility. The speed breakthrough will drive increased investment and interest from industry players seeking to leverage ultrafast volumetric printing for competitive advantage.

What to Watch

- Material Development: Advances in photopolymer resins with faster curing times and enhanced mechanical properties will be critical for broadening volumetric printing applications.

- Resolution and Accuracy: Monitoring improvements in the precision of volumetric printing to ensure parts meet stringent dimensional and surface finish requirements.

- Scalability: Whether the technology can be adapted to produce larger or multi-material parts without compromising speed or quality.

- Commercial Launches: Announcements from manufacturers or service providers adopting this ultrafast volumetric printing technology for real-world production.

- Intellectual Property and Collaboration: Patents filed and partnerships formed around volumetric printing innovations that could accelerate or restrict technology diffusion.

In summary, China’s record-setting volumetric 3D printing speed heralds a new chapter in additive manufacturing. While many technical and commercial questions remain, the potential to fabricate complex objects in under a second is poised to reshape how industries approach design, prototyping, and production.