What Happened

In a pioneering development reported by the MIT Media Lab, researchers have advanced the concept of hybrid living materials. These materials integrate living cells with synthetic scaffolds to create constructs that are not only structurally functional but also biologically active. This breakthrough represents a significant step toward embedding living systems within 3D printed objects, enabling materials that can sense, respond, and adapt to their environment.

Why It Matters

The fusion of living cells with 3D printed substrates opens a new paradigm in material science and manufacturing. Unlike traditional inert materials, hybrid living materials have the potential to self-heal, grow, and perform complex biological functions. This capability could revolutionize multiple sectors including healthcare, environmental sensing, construction, and wearable technology. For instance, living materials could be engineered to detect toxins, repair structural damage autonomously, or interface seamlessly with human tissues in biomedical implants.

By harnessing biological processes, these materials promise sustainability advantages as well, potentially reducing reliance on energy-intensive manufacturing and synthetic chemicals. They could usher in a new era where manufactured objects are dynamic participants rather than static tools.

Technical Context

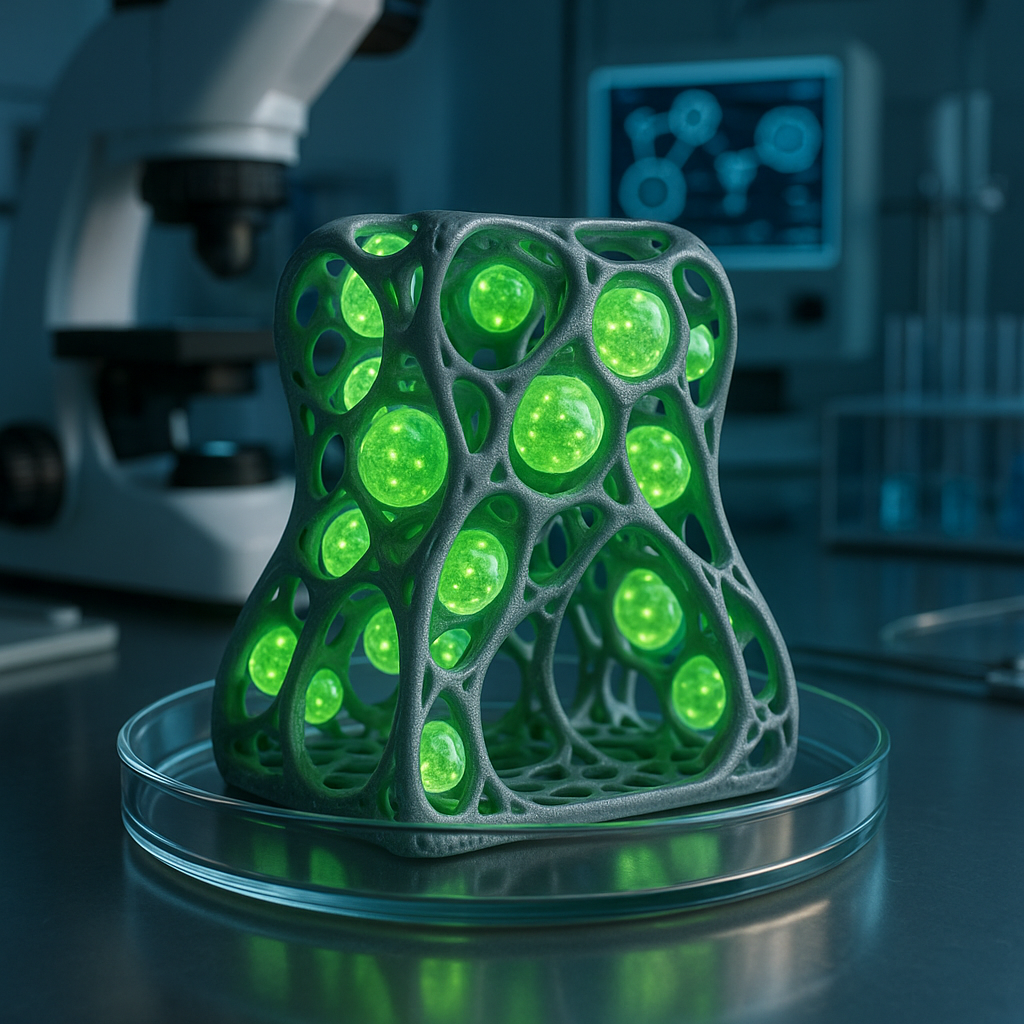

At the core of hybrid living materials is the integration of living cells—such as bacteria, fungi, or mammalian cells—within a non-living matrix that provides mechanical support and shape. The MIT Media Lab team has been developing methods to embed genetically engineered microbes into 3D printed scaffolds, allowing the living components to perform specific functions like sensing environmental cues or producing useful compounds.

Technically, this requires overcoming challenges related to cell viability during and after printing, ensuring nutrient and gas exchange, and maintaining stable interfaces between biological and synthetic components. Advances in bioinks—materials that can encapsulate living cells and be printed—are critical. These bioinks must balance printability, mechanical strength, and biocompatibility.

Furthermore, genetic engineering enables programming cells with desired behaviors, making the living materials programmable at the cellular level. This synthesis of synthetic biology and additive manufacturing is a frontier area requiring multidisciplinary expertise.

Near-term Prediction Model

Hybrid living materials are currently in the R&D stage, with pilot demonstrations validating feasibility but not yet ready for broad commercial deployment. Over the next 24 to 36 months, we can expect incremental advances in bioink formulations, improved cell survival rates, and more complex functional demonstrations such as environmental sensing patches or self-healing coatings.

Commercial applications will initially focus on niche areas where the unique advantages of living materials outweigh the challenges of regulatory approval and manufacturing complexity. These may include bioremediation devices, smart wound dressings, or adaptive architectural elements.

As the technology matures, integration with IoT and AI could enable living materials to act as autonomous agents within larger systems.

What to Watch

- Advances in bioink technology that improve cell viability and mechanical properties.

- New synthetic biology tools enabling more sophisticated cellular behaviors embedded in materials.

- Demonstrations of hybrid living materials in real-world pilot projects, especially in healthcare and environmental monitoring.

- Regulatory developments concerning the safety and environmental impact of deploying living materials.

- Collaborations between materials scientists, biologists, and engineers accelerating commercialization pathways.

While many technical details remain proprietary or under development, the trajectory set by MIT Media Lab’s work signals a transformative direction for 3D printing and materials science. The integration of living systems into manufactured objects could redefine how we design, use, and interact with the material world.