What Happened?

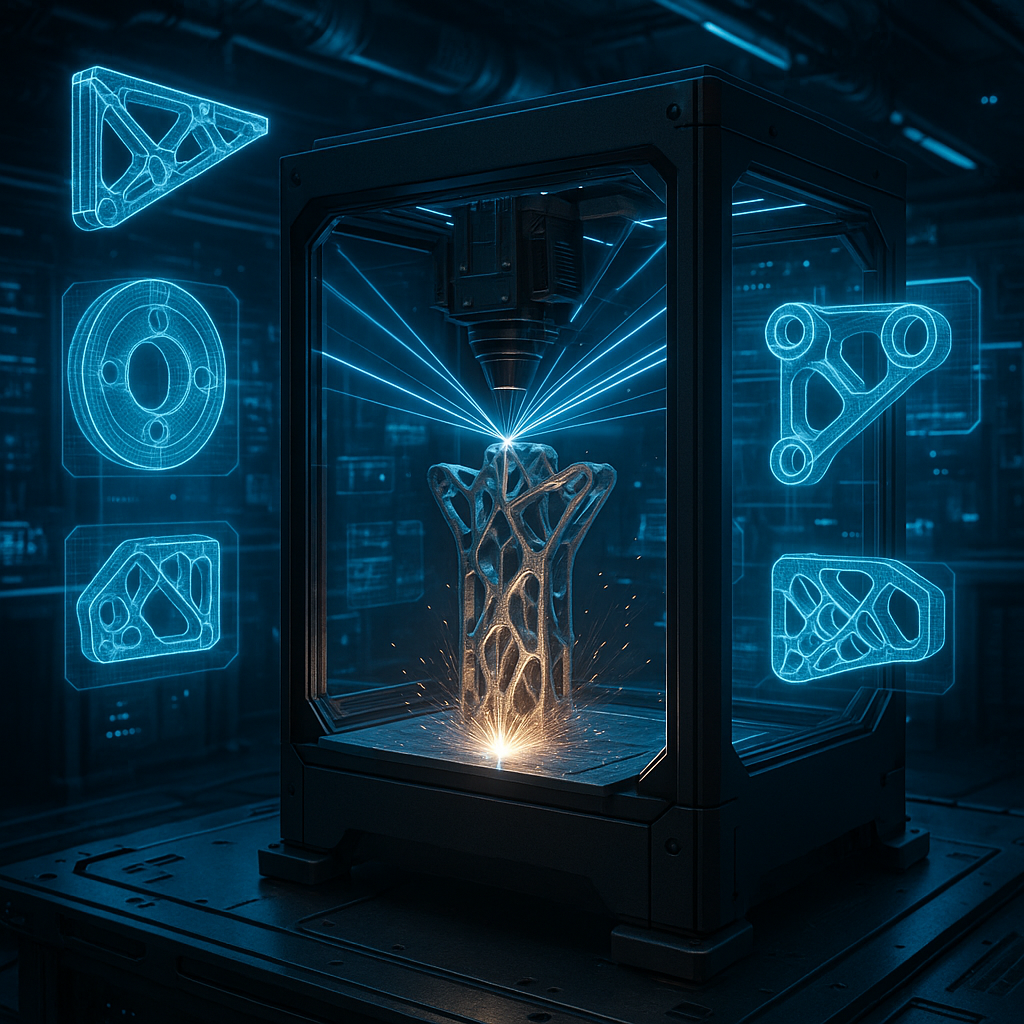

A U.S.-based start-up has recently announced its development of what it claims to be the world’s fastest metal 3D printer, as reported by All3DP on January 31, 2026. Although the start-up’s name and detailed specifications remain undisclosed publicly, the announcement has stirred interest in the additive manufacturing community due to its implications for volumetric 3D printing technology.

Why It Matters

The claim of achieving the fastest metal 3D printing speed is significant because metal additive manufacturing traditionally faces speed and scalability bottlenecks. Volumetric 3D printing, which builds objects layer-free by curing entire volumes simultaneously, could revolutionize how quickly and efficiently metal parts are produced. If the start-up’s technology truly leverages volumetric principles and achieves unprecedented build rates without compromising part quality, it could disrupt industries reliant on metal components, such as aerospace, automotive, and medical sectors.

Faster metal printing translates directly to reduced lead times, lower production costs, and opens new possibilities for complex geometries and on-demand manufacturing. This could accelerate adoption of volumetric 3D printing methods in metal, which have lagged behind polymer-based volumetric printing due to material and process challenges.

Technical Context

Volumetric 3D printing is an emerging additive manufacturing approach that differs fundamentally from traditional layer-by-layer methods. Instead of sequentially building thin layers, volumetric printing cures or solidifies the entire part volume simultaneously using intersecting light fields or other energy sources. This results in dramatically faster build times and smoother surface finishes.

While volumetric printing has seen success with photopolymers, applying it to metals involves overcoming substantial hurdles: metal powders require precise melting or sintering, managing thermal gradients is complex, and ensuring structural integrity is challenging. The start-up’s announcement suggests they may have developed a novel process or adapted volumetric principles to metal printing, possibly integrating advanced laser systems, optimized energy delivery, or innovative powder handling.

However, key technical details such as print resolution, material compatibility, mechanical properties of printed parts, and scalability remain unknown. Without independent validation or published data, the extent of the breakthrough remains speculative.

Near-term Prediction Model

Given the current information, the technology appears to be in the late R&D or pilot stage, with commercial deployment likely 12 to 24 months away if development proceeds smoothly. The impact score is high due to the potential to transform metal additive manufacturing, but confidence remains moderate because of the lack of detailed technical disclosures and third-party verification.

The start-up’s ability to scale the technology, ensure consistent part quality, and integrate into existing manufacturing workflows will be critical to success. Regulatory approvals and certification for critical industries may also influence time to market.

What to Watch

- Official technical releases or white papers from the start-up detailing their volumetric metal printing process.

- Demonstrations or case studies showcasing printed metal parts with performance metrics.

- Third-party testing or industry partnerships validating the speed and quality claims.

- Development of volumetric printing hardware capable of handling metal powders safely and reliably.

- Emerging competitors or complementary technologies in volumetric and metal 3D printing sectors.

In summary, while the announcement heralds an exciting potential leap in volumetric metal 3D printing speed, the additive manufacturing community awaits more concrete evidence and technical transparency to fully assess its impact.