What Happened

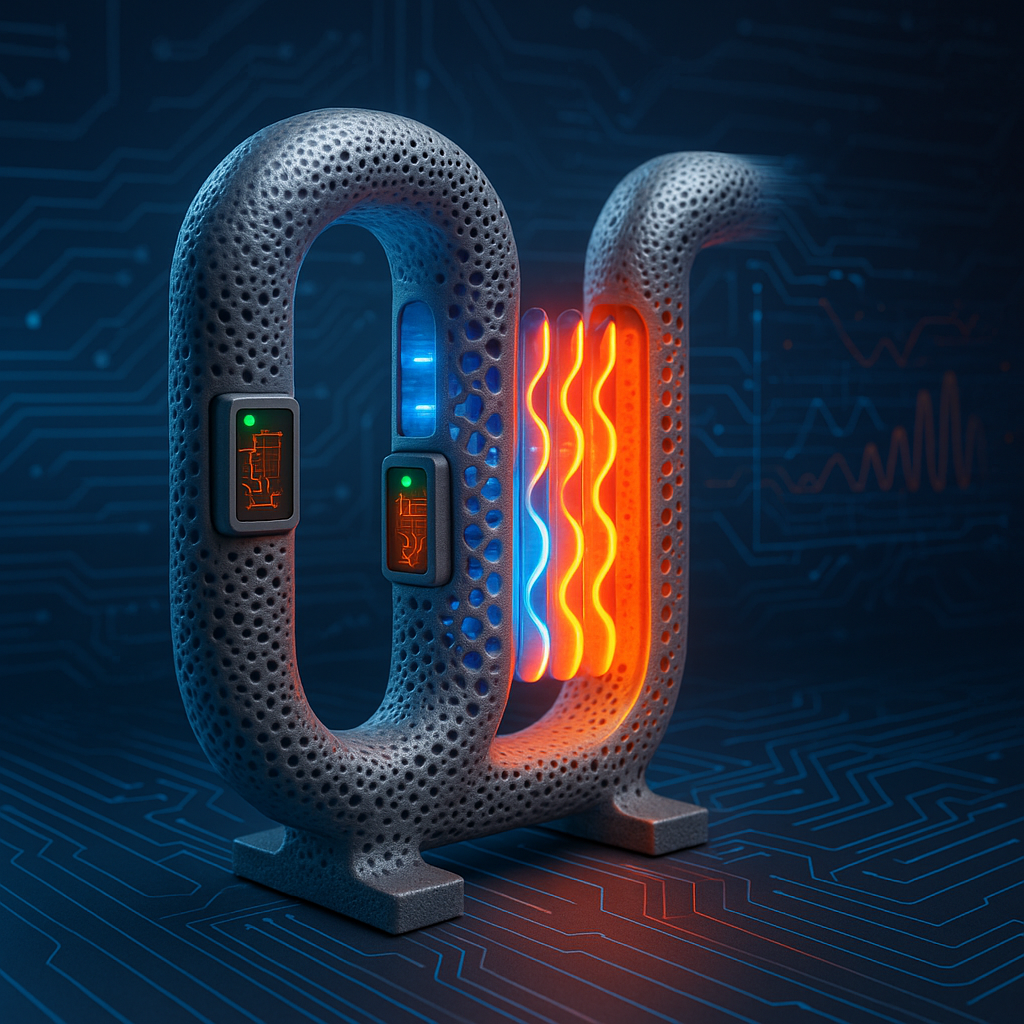

Recent developments in additive manufacturing have led to the creation of 3D printed smart heat pipes embedded with sensors and energy harvesting capabilities. This innovation, reported by eeNews Europe in September 2022, integrates sensing elements directly within heat pipes during the printing process, enabling real-time monitoring of thermal performance and harvesting energy from temperature gradients. This represents a significant step toward multifunctional thermal management systems that are both intelligent and self-sustaining.

Why It Matters

Heat pipes are critical components in managing heat dissipation for electronics, aerospace, and industrial applications. Traditional heat pipes, however, lack embedded intelligence to provide feedback on their operational status or efficiency. Embedding sensors directly within these pipes allows for continuous, in-situ monitoring of temperature, fluid flow, and potential faults, enabling predictive maintenance and improved system reliability.

Moreover, the addition of energy harvesting elements means these smart heat pipes could power their own sensors or other low-power devices, reducing the need for external power sources and wiring complexity. This convergence of thermal management, sensing, and energy harvesting in a single 3D printed component could transform design paradigms across multiple industries.

Technical Context

The reported technology utilizes advanced 3D printing techniques capable of embedding sensors during the manufacturing process without compromising the structural integrity or thermal conductivity of the heat pipes. While details on the specific sensor types and energy harvesting mechanisms remain limited, it is likely that thermoelectric generators or piezoelectric materials are integrated to convert temperature differentials into usable electrical energy.

The integration of sensors within a heat pipe is challenging due to the need for maintaining unobstructed fluid flow and heat transfer efficiency. The manufacturing process must ensure that sensor placement does not introduce thermal bottlenecks or mechanical weaknesses. The use of additive manufacturing offers a unique advantage here, enabling complex internal geometries and precise placement of functional materials that traditional manufacturing cannot achieve.

Currently, the technology appears to be at an experimental or pilot stage, with ongoing research required to optimize sensor durability, energy harvesting efficiency, and integration with external monitoring systems.

Near-Term Prediction Model

Over the next 12 to 24 months, we can expect incremental advancements in sensor integration techniques and energy harvesting efficiency within 3D printed heat pipes. Early pilot projects will likely emerge in high-value sectors such as aerospace, telecommunications, and high-performance computing where thermal management is critical and cost justification for smart components is strong.

Commercial adoption may initially focus on niche applications requiring enhanced monitoring capabilities, with broader industrial uptake following as manufacturing costs decrease and reliability improves. Partnerships between additive manufacturing firms, sensor technology providers, and end-users will be essential to accelerate development and integration.

What to Watch

- Advances in sensor miniaturization and durability compatible with 3D printing processes.

- Breakthroughs in embedded energy harvesting materials that can reliably power onboard sensors.

- Development of standardized interfaces and communication protocols for embedded sensor data extraction.

- Case studies demonstrating improved system reliability and maintenance cost reductions through smart heat pipe deployment.

- Regulatory and certification progress for smart components in safety-critical industries.

While the concept of 3D printed smart heat pipes with embedded sensors and energy harvesting is promising, many technical details and long-term performance data remain unknown. Continued research and pilot implementations will be pivotal in validating the technology’s practical value and guiding its path to commercialization.