What Happened

The Robins Air Force Base (AFB) Additive Manufacturing Lab has recently enhanced its capabilities by integrating robotic arm 3D printing technologies to support Air Force mission readiness. This development represents a strategic investment in advanced manufacturing techniques that go beyond traditional planar 3D printing. While specific technical details of the robotic arm systems used remain undisclosed, the lab is clearly advancing towards non-planar, multi-axis additive manufacturing to produce complex components with greater efficiency and precision.

Why It Matters

The integration of robotic arm 3D printing at Robins AFB is significant for several reasons. Firstly, it enables the production of aerospace-grade parts that are geometrically complex and difficult to manufacture using conventional methods. Multi-axis printing allows the deposition of material along curved and angled surfaces, reducing the need for support structures and post-processing. This capability directly contributes to faster turnaround times for critical parts, which is essential for maintaining Air Force readiness and operational capabilities.

Moreover, robotic arm 3D printing offers enhanced flexibility compared to fixed gantry systems. The ability to approach a part from multiple directions facilitates the creation of optimized designs that improve component performance and durability. This technological leap aligns with the broader defense sector trend towards adopting additive manufacturing to reduce supply chain vulnerabilities and enable on-demand production in diverse environments.

Technical Context

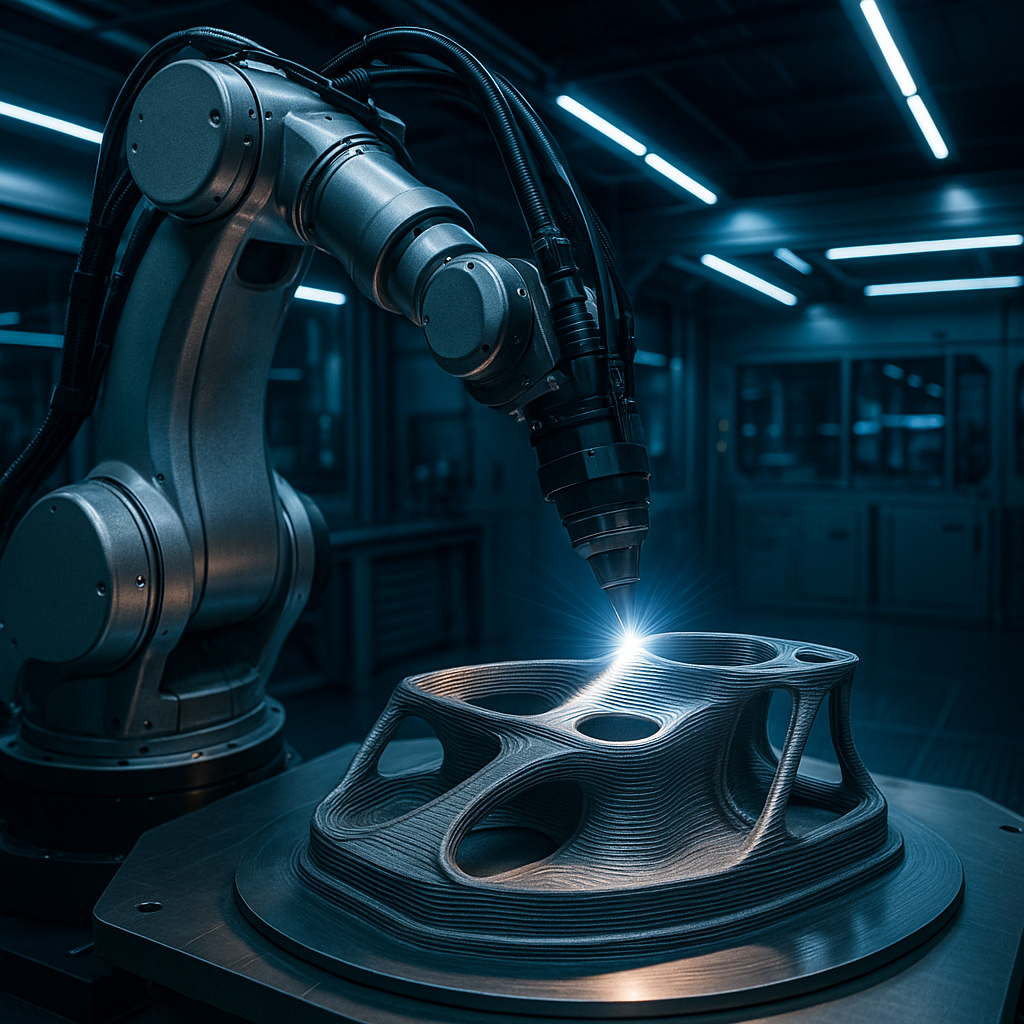

Robotic arm 3D printing is a subset of multi-axis additive manufacturing, which expands the traditional 3-axis (X, Y, Z) printing paradigm by introducing additional rotational degrees of freedom. These extra axes allow the print head to move around the part, depositing material on non-planar surfaces layer-by-layer. This approach contrasts with conventional layer-stacking methods that build parts layer upon flat layers, limiting geometric complexity and often requiring extensive support structures.

The technology typically involves industrial robotic arms equipped with extrusion or directed energy deposition print heads. This setup enables printing on curved surfaces, complex geometries, and even large-scale structures. Although the precise hardware and software stack employed at Robins AFB is not publicly detailed, the lab’s adoption of robotic arm 3D printing suggests advanced motion control, real-time path planning, and possibly in-situ monitoring to ensure part quality.

Challenges inherent to this technology include maintaining print accuracy across multiple axes, managing material properties during complex deposition paths, and integrating post-processing workflows. The defense sector’s stringent requirements for part certification and reliability add further complexity to the adoption of these emerging manufacturing methods.

Near-term Prediction Model

In the next 12 to 24 months, Robins AFB’s robotic arm 3D printing efforts are expected to transition from pilot demonstrations to more routine production of mission-critical components. We anticipate incremental improvements in process reliability, material variety, and software sophistication to handle complex toolpaths. The lab’s work will likely inform broader Air Force adoption and potentially catalyze collaboration with industry partners to scale multi-axis additive manufacturing capabilities.

As the technology matures, we expect to see expanded use cases including rapid prototyping of replacement parts, tooling fabrication, and low-volume production runs that leverage the agility of robotic arm systems. The ability to print parts with fewer supports and reduced post-processing will also drive cost and time efficiencies.

What to Watch

- Updates from Robins AFB and the Air Force on specific applications and materials used in robotic arm 3D printing.

- Advancements in multi-axis path planning software and real-time quality assurance techniques to enhance print accuracy.

- Integration of in-situ monitoring and adaptive control to mitigate defects during complex multi-axis printing.

- Collaborations between defense labs and commercial additive manufacturing companies to accelerate technology transfer.

- Regulatory and certification developments addressing the qualification of multi-axis printed aerospace components.

While the current public information provides a promising glimpse into the future of robotic arm 3D printing at Robins AFB, many technical specifics remain undisclosed. Continued transparency and research dissemination will be crucial for the broader 3D printing community to fully understand and leverage these advances.