What Happened

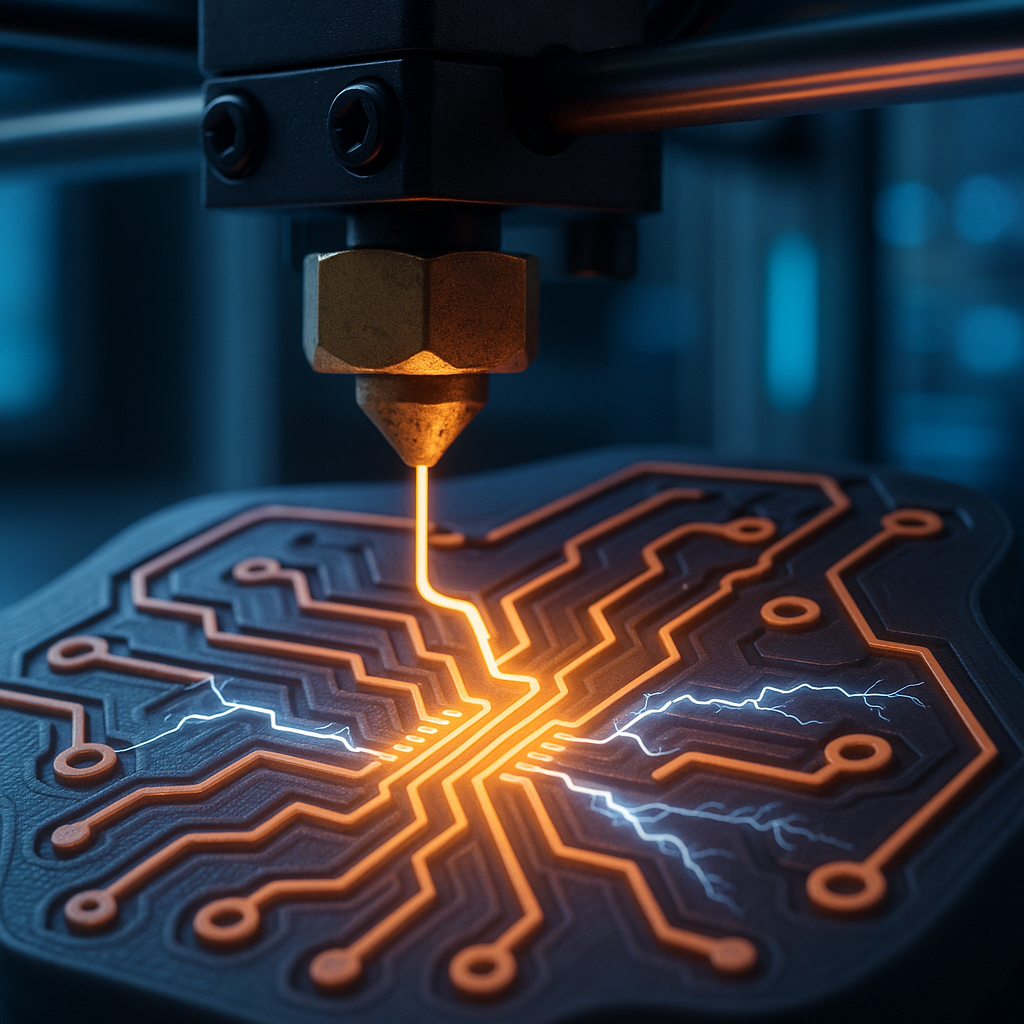

In a notable development for the 3D printing industry, Functionalize introduced a plastic conductive filament that significantly enhances the electrical conductivity of printed objects. Detailed in a 3D Printing Industry article published in 2014, this filament marks a leap forward in producing functional, electrically active 3D printed parts using standard additive manufacturing techniques.

Why It Matters

The introduction of conductive filaments opens up new frontiers for 3D printing beyond purely structural or aesthetic applications. By embedding electrical conductivity directly into printed plastics, manufacturers can create integrated circuits, sensors, antennas, and other electronic components within a single printed object. This convergence of mechanical and electrical functionality could reduce assembly complexity, lower costs, and enable highly customized smart devices.

Moreover, conductive filaments support the broader trend of smart and bio-embedded materials, where 3D printed parts interact dynamically with their environment or biological systems. This capability is especially promising for wearable electronics, medical devices, and Internet of Things (IoT) applications.

Technical Context

Traditional 3D printing filaments such as PLA or ABS are electrically insulating, limiting their use in electronics integration. Functionalize’s conductive filament incorporates conductive fillers—likely carbon-based materials such as carbon black, graphene, or carbon nanotubes—dispersed within a polymer matrix. This composition enables electrons to travel through the printed structure, imparting measurable conductivity.

Key technical challenges include maintaining printability and mechanical properties while achieving sufficient conductivity. The conductive filler loading must be balanced to avoid filament brittleness or nozzle clogging. Additionally, the conductivity levels achieved depend on filler type, dispersion quality, and printing parameters.

While the exact specifications of Functionalize’s filament remain undisclosed, the breakthrough suggests a commercially viable approach to producing conductive 3D printed parts without requiring post-processing or embedding discrete conductive elements.

Near-term Prediction Model

Over the next 12 to 24 months, conductive filaments like those from Functionalize are expected to transition from niche R&D tools to more widespread commercial adoption, particularly in prototyping and low-volume production of smart devices. Advances in material formulations will likely improve conductivity, flexibility, and compatibility with various 3D printers.

Integration with multi-material printing platforms could enable complex devices combining conductive, insulating, and structural materials in a single print job. However, challenges remain in scaling production, ensuring consistent quality, and meeting regulatory standards for electronic components.

What to Watch

- Material improvements that enhance conductivity without compromising printability or mechanical strength.

- Development of multi-material 3D printers optimized for conductive and non-conductive filaments.

- Emergence of standardized testing and certification protocols for 3D printed electronic components.

- Applications in wearable electronics, medical sensors, and IoT devices demonstrating real-world functionality.

- Collaborations between filament manufacturers and electronics companies to co-develop integrated solutions.

While the initial announcement from 2014 set the stage, continuous innovation and validation are critical to fully realize the potential of conductive filaments in smart and bio-embedded 3D printing applications.