What Happened

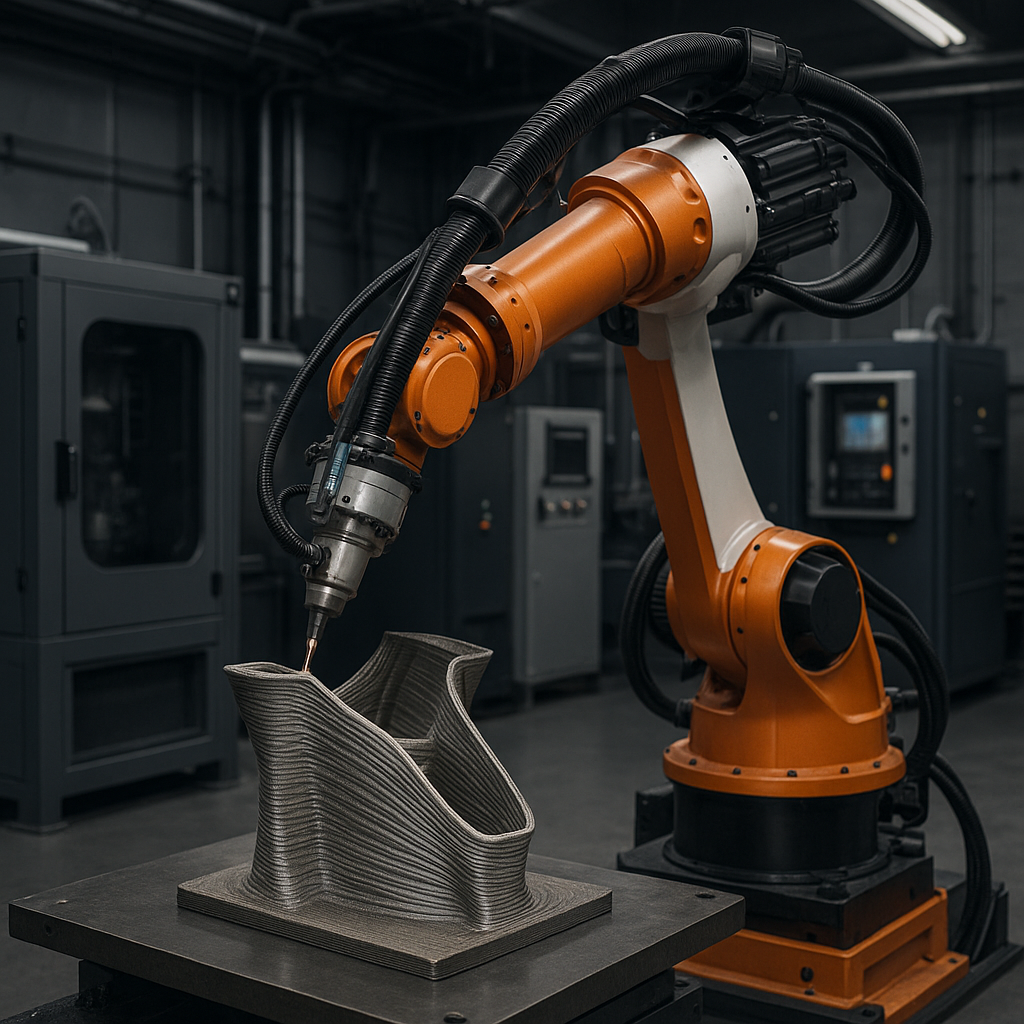

The Robins Air Force Base (AFB) Additive Manufacturing Lab recently made significant strides in advancing the use of robotic arm 3D printing technologies to support Air Force readiness. According to a report from eglin.af.mil, the lab is integrating robotic arms equipped with additive manufacturing capabilities to produce complex aerospace components with enhanced precision and speed.

Why It Matters

This development is a critical step in modernizing military manufacturing processes. Robotic arm 3D printing enables non-planar and multi-axis printing, which allows for the creation of parts that are difficult or impossible to fabricate using traditional layer-by-layer planar methods. For the Air Force, this means faster turnaround times for replacement parts, reduced dependency on external supply chains, and the ability to produce mission-critical components on-demand directly at maintenance hubs like Robins AFB.

Moreover, the flexibility of robotic arms in additive manufacturing opens new possibilities for repairing and customizing parts, which can extend the life of existing equipment and reduce costs. This capability directly enhances operational readiness by minimizing downtime and improving the resilience of logistics and maintenance operations.

Technical Context

Robotic arm 3D printing leverages multi-axis kinematics, typically six degrees of freedom, allowing the print head to move and deposit material along complex trajectories. Unlike conventional 3D printers that rely on planar, layer-by-layer deposition, these robotic systems can print on curved surfaces and build parts with continuous, non-planar layers. This approach reduces the need for support structures, improves mechanical properties by aligning print paths with stress directions, and enables the fabrication of geometries with undercuts and intricate features.

The Robins AFB lab is likely utilizing advanced materials compatible with robotic arm extrusion or directed energy deposition processes, although specific material systems and printer models have not been disclosed. Integration with in-situ monitoring and adaptive control systems is also a probable focus, ensuring consistent quality despite the complexity of multi-axis printing.

Near-term Prediction Model

Given the current trajectory, within 12 to 24 months Robins AFB’s robotic arm 3D printing capabilities will transition from pilot demonstrations to more routine operational use for producing select aerospace components. The maturity stage is currently at the Pilot level, with ongoing validation and process optimization underway.

We anticipate a high impact score around 80 due to the strategic value of additive manufacturing in defense logistics and maintenance. Confidence in this prediction is moderate (around 70) because of the technical challenges inherent in scaling multi-axis printing for critical aerospace applications and the need to comply with stringent military standards.

What to Watch

- Announcements of specific parts or assemblies successfully produced and certified using robotic arm 3D printing at Robins AFB.

- Development of new materials tailored for multi-axis additive manufacturing processes in defense applications.

- Integration of real-time monitoring and closed-loop control systems to improve print reliability and part quality.

- Collaborations between military labs and industry partners to commercialize robotic arm 3D printing technologies.

- Regulatory and certification milestones for additive manufactured aerospace components printed via robotic arms.

While the exact details of the robotic arm systems and materials used remain undisclosed, the Robins AFB initiative clearly positions multi-axis 3D printing as a transformative technology for military readiness. Continued advancements and successful demonstrations will likely accelerate adoption across other defense branches and high-performance manufacturing sectors.