What Happened

A recent interview with Flexam published by 3Druck.com on February 13, 2026 highlights a critical bottleneck in the advancement of multi-axis 3D printing: software. Flexam, a company specializing in multi-axis additive manufacturing, emphasized that despite hardware innovations enabling non-planar printing paths and complex orientations, software remains the biggest hurdle preventing widespread adoption and scaling of this technology.

Why It Matters

Multi-axis and non-planar 3D printing methods promise to revolutionize additive manufacturing by allowing prints with fewer supports, improved surface finish, and greater mechanical properties due to optimized layer orientations. However, the inability to efficiently plan and control these complex print paths through software limits these benefits from reaching industrial-scale production. Overcoming this software challenge could unlock significant productivity gains, reduce post-processing, and enable new design freedoms, ultimately accelerating the adoption of multi-axis printing in sectors like aerospace, automotive, and medical devices.

Technical Context

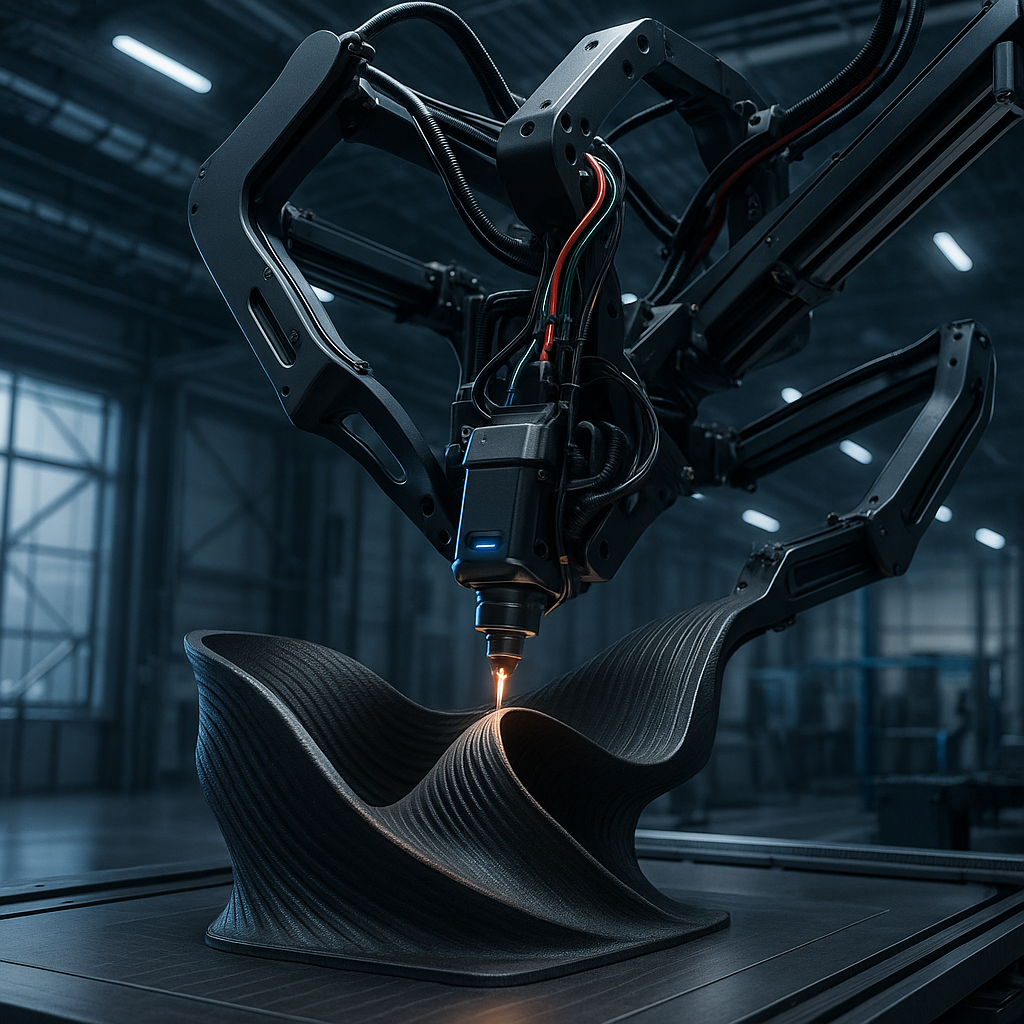

Traditional 3D printing operates in a planar, layer-by-layer fashion, typically along the XY plane with vertical Z-axis movement. Non-planar 3D printing, by contrast, involves printing along curved or angled surfaces, and multi-axis systems (such as 5-axis or 6-axis machines) can reorient the print head or part dynamically during fabrication. This complexity allows for continuous deposition on non-flat surfaces, reducing the need for support structures and enabling anisotropic material properties tailored to load directions.

However, this complexity introduces formidable challenges in software development. Slicing software must generate toolpaths that consider machine kinematics, collision avoidance, material flow, and thermal effects in three or more rotational axes. Existing slicing tools primarily target planar layers and struggle with the computational load and geometric complexity of multi-axis trajectories. Flexam’s insights indicate that current software solutions are either too simplistic, lacking robust multi-axis path planning, or too specialized and costly for widespread use.

Moreover, integrating real-time feedback and adaptive control into the software stack is necessary to handle the dynamic variables inherent in multi-axis printing, such as varying print speeds and orientations. This integration remains underdeveloped, leaving a gap between hardware capabilities and software usability.

Near-term Prediction Model

Given the current state, non-planar multi-axis 3D printing software is in the Pilot maturity stage. Over the next 12 to 24 months, incremental advances are expected as startups and research institutions develop more sophisticated algorithms and machine learning approaches for toolpath optimization. However, widespread commercial adoption will likely lag until software platforms become more user-friendly, interoperable, and cost-effective.

Impact score: 75/100 — The potential productivity and quality improvements are substantial, but software hurdles constrain near-term impact.

Confidence: 70/100 — The hardware progress is clear, but software development timelines depend heavily on breakthroughs in computational geometry and integration.

What to Watch

- Emergence of modular, open-source multi-axis slicing software that can be adapted across different hardware platforms.

- Advances in AI-driven toolpath planning that can dynamically optimize print orientation and speed in real time.

- Collaborations between hardware manufacturers and software developers to produce integrated solutions.

- Case studies demonstrating cost and time savings from early adopters in aerospace or medical sectors.

- Standardization efforts for multi-axis printing protocols to enable broader ecosystem support.

In conclusion, while hardware innovations have brought multi-axis non-planar 3D printing close to practical reality, software remains the gating factor for scaling this transformative technology. Keeping a close eye on software development trends and collaborations will be essential for stakeholders aiming to leverage the full potential of non-planar additive manufacturing.