Recent developments in 3D printing have expanded beyond traditional single-machine setups into realms of coordinated, multi-unit operations known as swarm and collaborative printing. This emerging approach is gaining traction as a critical aspect of print farm automation, promising to revolutionize how additive manufacturing scales and adapts to complex production demands.

What Happened

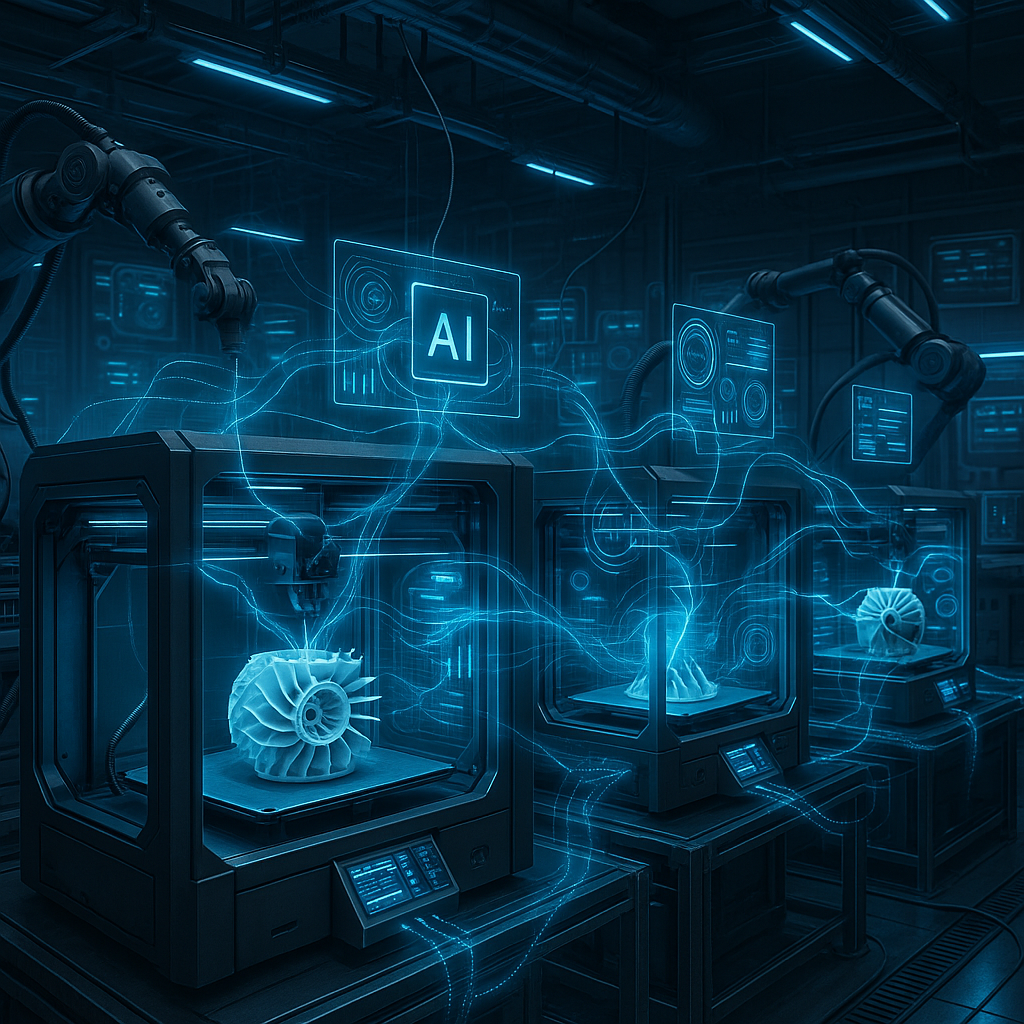

While 3D-printed food and other novel applications have captured headlines recently, the underlying technologies enabling efficient mass production remain under-covered. Swarm and collaborative printing refer to systems where multiple 3D printers operate in a coordinated fashion, sharing tasks, optimizing workflow, and often communicating in real-time to increase throughput and reduce downtime. This concept extends the idea of print farms—groups of printers running independently—by introducing intelligent orchestration and cooperation between units.

Unlike traditional print farms where each printer functions as a silo, swarm printing integrates hardware and software to create a networked ecosystem. This allows printers to dynamically allocate jobs, balance workloads, and even assist one another with complex assemblies that require multiple simultaneous processes.

Why It Matters

The significance of swarm and collaborative printing lies in its potential to address key bottlenecks in additive manufacturing. Print farms today face challenges such as inefficient job scheduling, underutilized capacity, and high operational costs due to manual oversight. By automating coordination across machines, swarm systems can dramatically improve productivity, consistency, and scalability.

Moreover, as industries demand faster turnaround times and greater customization, the ability to run multiple printers harmoniously becomes a competitive advantage. Swarm printing also opens doors to innovative manufacturing approaches like distributed production, where geographically dispersed printers collaborate virtually, reducing shipping costs and lead times.

Technical Context

Swarm and collaborative printing rely on several technological pillars:

- Networked Communication: Printers are connected via robust communication protocols, enabling real-time data exchange about job status, printer health, and environmental conditions.

- Centralized or Distributed Control Software: Advanced software platforms manage job queues, prioritize tasks, and optimize resource allocation across the printer network.

- Machine Learning and AI: Algorithms analyze performance metrics to predict maintenance needs, optimize print parameters, and dynamically adapt workflows.

- Standardized Hardware Interfaces: Uniform machine interfaces facilitate interoperability, allowing printers from different manufacturers to collaborate within the same swarm.

Despite these advances, many aspects remain in development. For example, seamless interoperability across diverse printer models is still limited, and comprehensive standards for swarm communication have yet to be widely adopted.

Near-term Prediction Model

Over the next 12 to 24 months, swarm and collaborative printing are expected to transition from pilot projects to early commercial deployments, primarily within specialized industrial sectors such as aerospace, automotive, and medical devices. Companies investing in print farm automation will increasingly integrate swarm capabilities to enhance efficiency and reduce labor costs.

However, widespread adoption in smaller-scale or consumer markets may lag due to complexity and upfront investment requirements. The maturation of user-friendly software interfaces and standardized protocols will be key enablers.

What to Watch

- Development of open standards for printer communication and interoperability to accelerate ecosystem growth.

- Advances in AI-driven print scheduling and predictive maintenance that improve swarm reliability.

- Integration of swarm printing with other Industry 4.0 technologies, including IoT sensors and digital twins.

- Emergence of hybrid print farms combining different additive technologies collaboratively.

- Case studies demonstrating cost savings and quality improvements from swarm implementations.

In summary, while still emerging, swarm and collaborative 3D printing represent a transformative evolution in print farm automation. Their ability to orchestrate multiple machines intelligently promises to unlock new levels of productivity and flexibility in additive manufacturing. Staying informed on these developments is essential for stakeholders aiming to harness the full potential of 3D printing’s next frontier.