What Happened

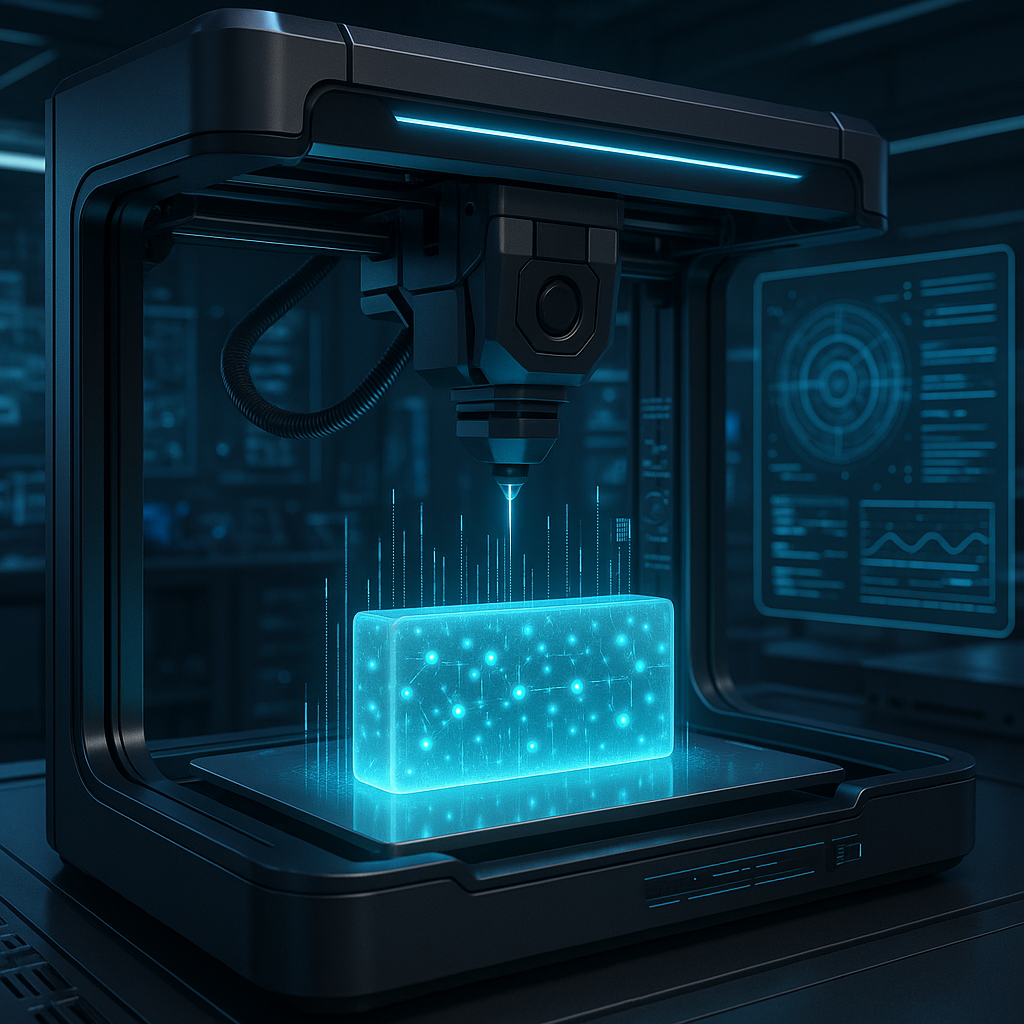

Recent developments in the 3D printing industry, highlighted in the 3D Printing News Briefs, February 25, 2023 from 3DPrint.com, underscore a growing focus on integrating embedded sensors within 3D printed materials. Although the news briefs cover a range of topics—from anatomic models to horse trailers—the underlying technological trend is the embedding of sensors directly into 3D printed structures, enabling smarter, more responsive materials.

Why It Matters

Embedding sensors into 3D printed parts represents a paradigm shift in additive manufacturing, moving beyond static components to dynamic, interactive systems. This integration enables real-time monitoring, adaptive responses, and enhanced functionality across sectors such as healthcare, automotive, aerospace, and consumer products. For example, in medical anatomic models, embedded sensors could provide feedback on stress or strain during surgical training or implant testing, improving outcomes. In transportation, sensor-embedded trailers could monitor structural integrity or environmental conditions, enhancing safety and maintenance.

Smart and bio-embedded materials with integrated sensing capabilities promise to revolutionize how objects interact with their environment and users, bridging the gap between physical objects and digital intelligence.

Technical Context

Embedding sensors within 3D printed materials involves several technical challenges and innovations. The primary technical requirement is the compatibility of sensor materials and electronics with the printing process, whether it be fused deposition modeling (FDM), stereolithography (SLA), selective laser sintering (SLS), or other methods. Sensors must withstand the thermal, mechanical, and chemical conditions of printing without degradation.

Multimaterial printing techniques are often employed, allowing conductive inks, flexible substrates, and sensor elements to be incorporated layer-by-layer. Advances in printable electronics, such as conductive polymers and nanomaterials, facilitate embedding strain gauges, temperature sensors, pressure sensors, and even biochemical sensors directly into printed parts.

Bio-embedded materials go a step further by integrating living cells or biomolecules with sensors, enabling applications in tissue engineering and wearable health monitoring. However, maintaining sensor functionality while ensuring biocompatibility and structural integrity remains an ongoing research focus.

Despite these advances, details on specific sensor types, integration methods, or performance metrics from the February 2023 briefs are limited, indicating the field is still evolving and underreported.

Near-term Prediction Model

The integration of embedded sensors in 3D printing is currently at the Pilot stage, with several prototypes and limited commercial applications emerging. Over the next 12 to 24 months, we anticipate increased adoption driven by improvements in multimaterial printers, printable electronics, and sensor miniaturization. Industries such as healthcare and aerospace are likely early adopters due to the high value of sensing-enabled parts.

Impact is expected to be moderate to high (impact score ~75) as embedded sensors enhance product functionality and enable new use cases, though widespread commercialization will require overcoming cost, reliability, and standardization challenges. Confidence in this prediction is moderate (~70) given the nascent nature of the technology and market dynamics.

What to Watch

- Advances in printable conductive materials and inks suitable for sensor fabrication.

- Development of standardized processes for embedding sensors during printing across different technologies.

- Case studies demonstrating real-world applications of sensor-embedded 3D printed parts, especially in medical and aerospace sectors.

- Collaborations between 3D printing firms and sensor manufacturers to accelerate integration.

- Regulatory developments and certification pathways for sensor-embedded bio-materials and medical devices.

In summary, embedded sensors in 3D printing represent a frontier of smart and bio-embedded materials that promises to transform additive manufacturing from producing passive objects to creating intelligent, responsive systems. While currently in early stages, continued innovation and cross-industry collaboration will be key to unlocking their full potential.