What Happened

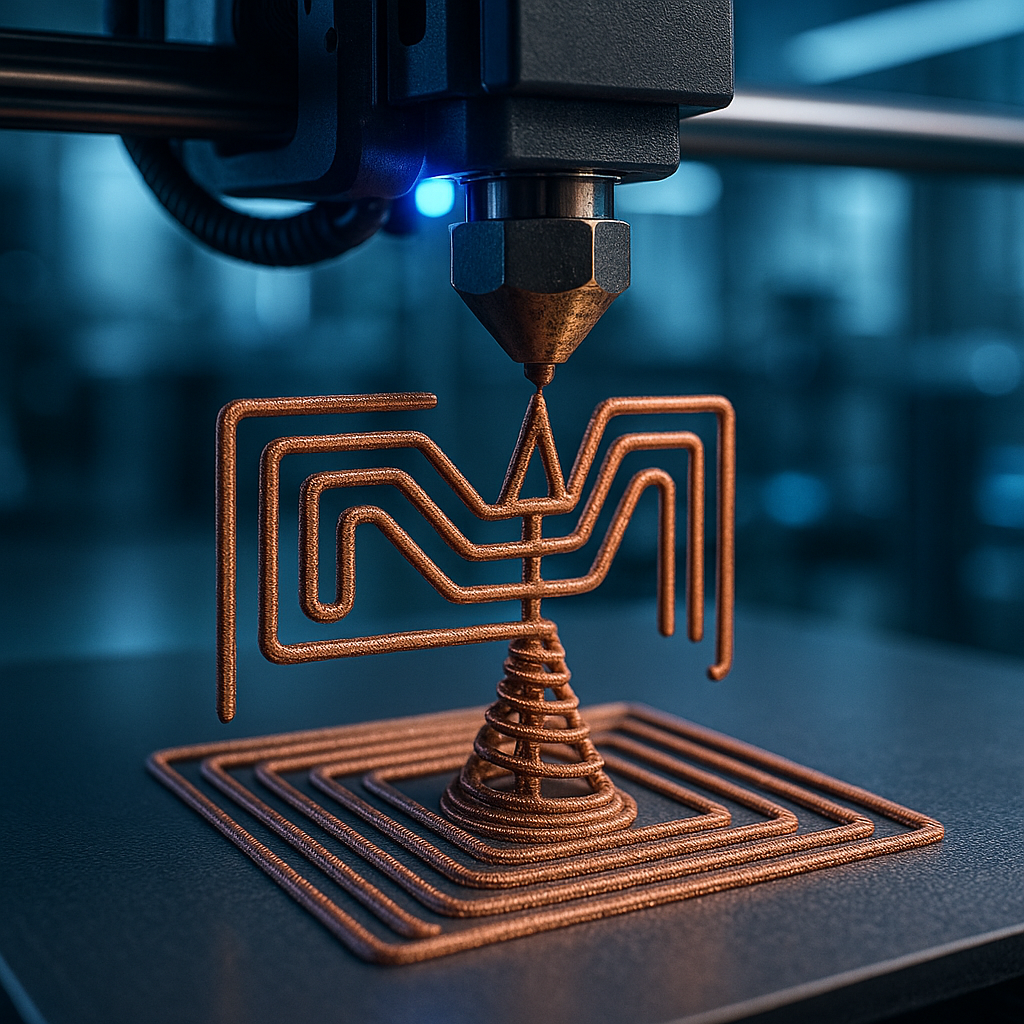

Recent developments in the use of conductive filament for 3D printing have been showcased through the fabrication of functional antennas, as reported by 3DPrint.com. This work explores how conductive filament can be effectively utilized to print antennas, simultaneously serving as a testbed for both the material’s electrical properties and the optimization of 3D printing parameters. The approach represents a practical intersection of material science and additive manufacturing process engineering.

Why It Matters

The ability to 3D print antennas with conductive filament is significant because it demonstrates a functional application of smart, bio-embedded materials in additive manufacturing. Antennas are integral to wireless communication devices, and fabricating them with 3D printing introduces unprecedented design flexibility, cost efficiency, and rapid prototyping capabilities. This development could accelerate the integration of conductive materials into smart devices, wearable technology, and embedded sensors, which rely heavily on customized antenna geometries for optimized performance.

Moreover, testing conductive filaments through antenna fabrication provides valuable feedback on conductivity, print resolution, and layer adhesion—critical factors that influence the reliability and efficiency of printed electronics. This aligns with the broader industry trend toward embedding electronic functionalities directly into 3D printed objects, thereby advancing the frontier of multifunctional materials.

Technical Context

Conductive filaments typically consist of polymer matrices infused with conductive fillers such as carbon black, graphene, or metal particles. Printing antennas requires balancing electrical conductivity with mechanical printability. The challenge lies in achieving sufficient conductivity without compromising filament extrusion and layer bonding during printing.

The reported testing involves varying 3D printing parameters such as nozzle temperature, print speed, layer height, and infill density to optimize the conductive filament’s performance in antenna structures. These parameters influence the microstructure of printed layers, affecting the continuity of conductive pathways and ultimately the antenna’s signal transmission capabilities.

While the exact filament composition and printing parameters used in the study are not detailed in the source, the methodology underscores the need for systematic experimentation to tailor conductive filament properties and printing settings for specific electronic applications.

Near-term Prediction Model

In the near term, conductive filament 3D printing for antennas and similar electronic components is transitioning from research and pilot phases toward commercial viability. The technology maturity remains in the Pilot stage, with expected broader adoption within 12 to 24 months as material formulations improve and printing protocols become standardized.

The impact score is estimated at 75 out of 100, reflecting substantial potential to disrupt traditional antenna manufacturing by enabling customization and rapid iteration. Confidence in this prediction is moderate at 65 out of 100, acknowledging ongoing challenges in filament consistency and print quality.

What to Watch

- Development of new conductive filament composites with enhanced conductivity and mechanical properties.

- Refinement of 3D printing parameters specifically optimized for electronic functionality rather than just mechanical form.

- Integration of multi-material printing that combines conductive and insulating materials in a single print job.

- Emergence of standards and testing protocols for printed electronic components to ensure reliability and safety.

- Applications expanding beyond antennas to include sensors, wearable electronics, and embedded bioelectronics.

Overall, 3D printing antennas using conductive filament represents a promising convergence of smart materials and additive manufacturing. Continued innovation and cross-disciplinary collaboration will be essential to overcome current limitations and unlock the full potential of bio-embedded and conductive 3D printed materials.