What Happened

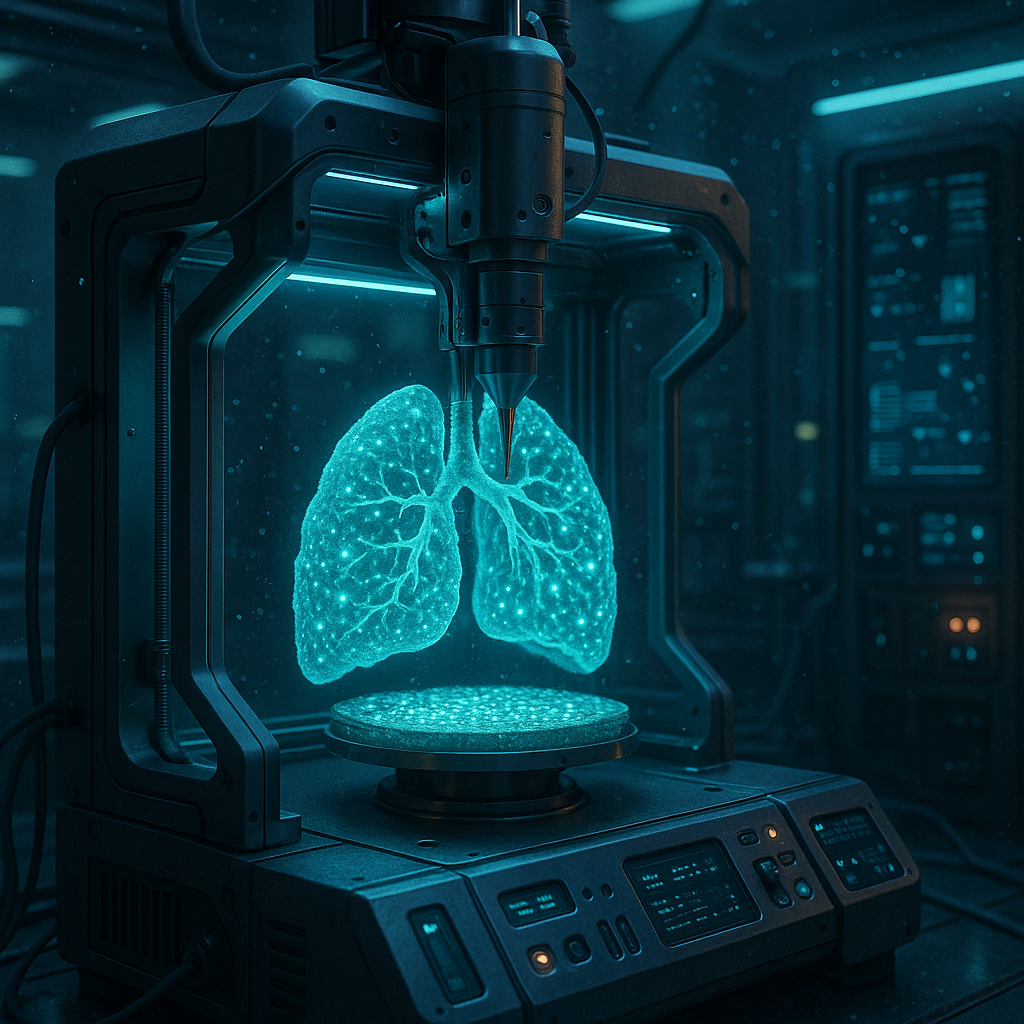

Researchers have recently demonstrated a groundbreaking advancement in bioprinting by successfully 3D printing living lung cells layer by layer under extreme environmental conditions. This innovative work, reported by EurekAlert!, marks a significant step forward in the realm of smart and bio-embedded materials, particularly in the fabrication of living tissue structures through 3D printing technology.

Why It Matters

The ability to 3D print living lung cells in harsh environments is a vital breakthrough with far-reaching implications. Lung tissue is notoriously complex due to its delicate cellular architecture and the necessity for precise oxygen exchange functionality. Successfully printing viable lung cells layer by layer opens new pathways for regenerative medicine, personalized organ repair, and even the development of biohybrid devices capable of functioning in adverse conditions.

Moreover, this technology pushes the boundaries of bio-embedded materials by integrating living cells directly into 3D printed constructs that can potentially respond to environmental stimuli, self-repair, or even adapt dynamically. This aligns with the growing demand for smart materials that not only perform structural roles but also possess biological functionality.

Technical Context

3D bioprinting has long been challenged by the need to maintain cell viability and function during and after printing. Achieving this in extreme environments—such as low oxygen, temperature fluctuations, or mechanical stress—adds another layer of complexity. The reported advancement suggests the development of specialized bioinks and printing protocols that protect living lung cells throughout the fabrication process.

Details on the exact bioink composition, printing parameters, and environmental controls remain limited from the source. However, it is likely that the approach involves hydrogels or biomaterials optimized for lung cell adhesion and growth, combined with bioreactor conditions that mimic physiological environments post-printing. The layer-by-layer technique ensures precise spatial organization, critical for replicating the lung’s alveolar structures.

Near-term Prediction Model

This technology currently resides in the Research & Development phase. Over the next 18 to 24 months, we anticipate pilot studies focusing on functional testing of printed lung tissues in controlled laboratory settings. Key milestones will include demonstrating sustained cell viability, gas exchange functionality, and integration with host tissue in animal models.

Commercialization remains several years away, pending advances in scalability, reproducibility, and regulatory approvals. However, the impact score is high given the potential to revolutionize respiratory medicine and bio-embedded smart materials.

What to Watch

- Publication of detailed methodologies and bioink formulations enabling printing in extreme conditions.

- Advances in bioreactor and environmental control technologies that support post-printing tissue maturation.

- Preclinical studies demonstrating functional lung tissue integration and repair capabilities.

- Cross-disciplinary collaborations combining materials science, cell biology, and 3D printing engineering.

- Regulatory developments and ethical considerations around implanted bio-printed living tissues.

While the current report highlights a promising frontier, additional data is needed to fully assess the robustness and reproducibility of this approach. Continued monitoring of research outputs and translational efforts will be crucial to understanding the trajectory and real-world applications of bio-embedded 3D printed lung tissue.