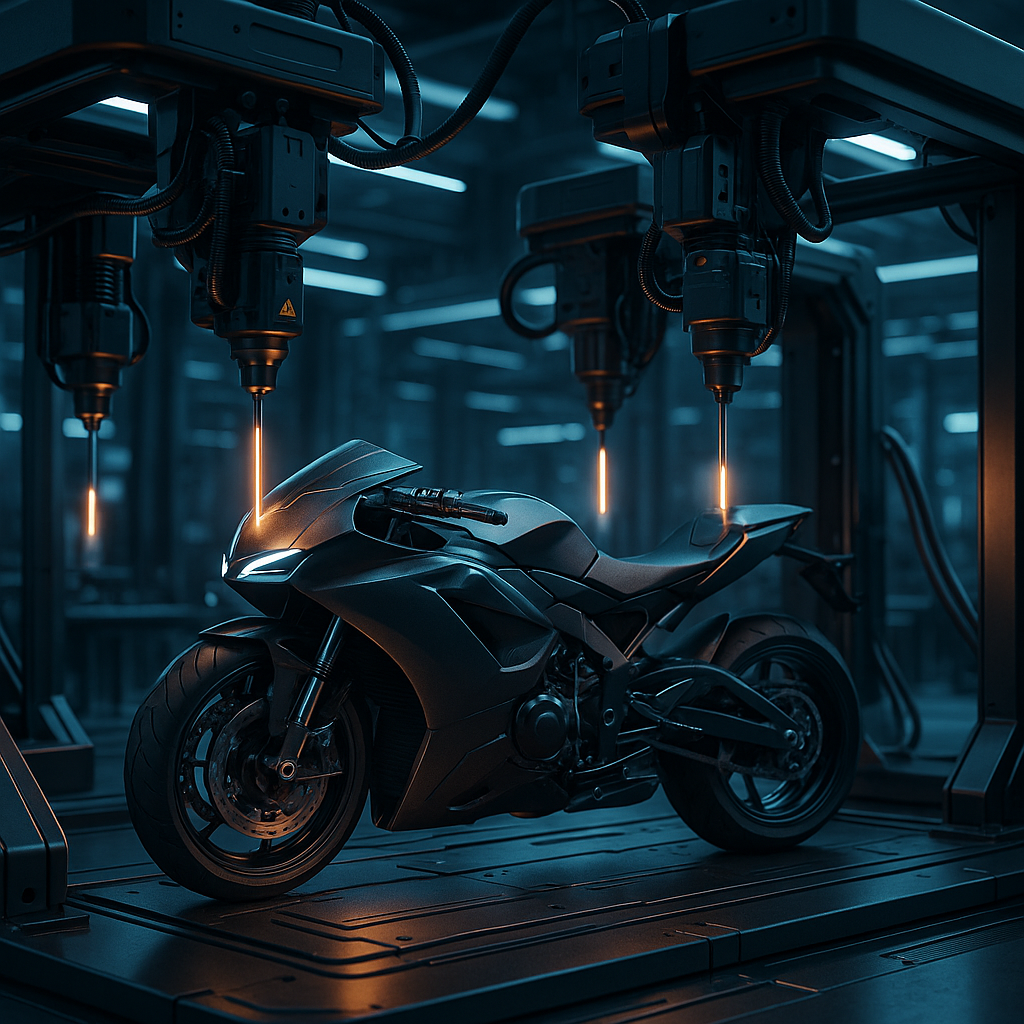

In a recent development highlighted by CSIRO, the Commonwealth Scientific and Industrial Research Organisation (CSIRO) in partnership with Singapore’s A*STAR are driving forward innovative 3D-printed solutions specifically targeting motorcycle manufacturing. This collaboration represents a significant stride in the application of collaborative printing technologies within the automotive sector, especially in the niche of motorcycles.

What Happened

CSIRO and A*STAR have jointly developed advanced 3D printing techniques that enable the production of motorcycle components through a collaborative printing approach. While the exact technical details remain limited in the public domain, the partnership focuses on leveraging additive manufacturing to create complex, lightweight, and high-performance parts that are traditionally challenging to fabricate using conventional methods. The initiative appears to integrate swarm or collaborative printing concepts, where multiple printers or print heads work in coordination to produce parts more efficiently and with enhanced design freedom.

Why It Matters

This advancement is important for several reasons. First, motorcycles benefit greatly from lightweight and structurally optimized components, which can improve fuel efficiency, performance, and safety. Collaborative 3D printing can accelerate prototyping cycles and reduce costs, enabling manufacturers to iterate designs rapidly and customize parts for specific needs. Additionally, the ability to produce parts on-demand through distributed printing networks can reduce inventory and supply chain dependencies.

Moreover, this project underscores the growing trend toward decentralized manufacturing ecosystems where multiple 3D printers operate in concert, a concept known as swarm or collaborative printing. By harnessing this approach, manufacturers can enhance throughput, scalability, and resilience against disruptions—a critical factor as global supply chains face increasing volatility.

Technical Context

Collaborative printing, often synonymous with swarm 3D printing, involves coordinating multiple printing devices or print heads to fabricate a single part or batch of parts simultaneously. This can reduce build times, enable larger or more complex geometries, and improve material utilization. The CSIRO and A*STAR effort likely incorporates advanced software algorithms for print path optimization, real-time synchronization, and quality assurance across multiple printing units.

In motorcycle manufacturing, parts such as frames, brackets, and engine components require high strength-to-weight ratios and precise tolerances. Additive manufacturing materials, including high-performance polymers and metal alloys, combined with collaborative printing processes, can meet these stringent requirements. However, challenges remain in ensuring consistent inter-layer adhesion, managing thermal stresses, and validating mechanical properties at scale.

Near-term Prediction Model

Given the current information, this collaborative printing initiative is positioned at the Pilot stage of maturity. The technology is beyond basic research but is still being refined and validated for industrial application. Within the next 12 to 18 months, we anticipate pilot projects expanding to include functional prototypes and limited production runs, possibly with select motorcycle manufacturers testing the feasibility of these 3D-printed components in real-world conditions.

The impact score is moderate to high (around 70/100), reflecting the potential to disrupt traditional manufacturing workflows and supply chains in motorcycle production. Confidence in this timeline is medium (around 65/100), primarily due to unknowns about scalability, regulatory approvals, and material certifications.

What to Watch

- Further technical disclosures from CSIRO and A*STAR detailing the specific collaborative printing methods, materials used, and performance metrics.

- Case studies or pilot programs involving motorcycle manufacturers adopting these 3D-printed parts in testing or limited production.

- Advancements in software and hardware enabling more seamless coordination between multiple printers or print heads.

- Regulatory developments concerning safety standards and certification of additively manufactured motorcycle components.

- Expansion of collaborative printing concepts into other automotive or aerospace sectors, indicating broader industrial adoption.

While the CSIRO and A*STAR collaboration marks a promising step in the evolution of swarm and collaborative 3D printing, further transparency and demonstration of practical outcomes will be essential to fully assess its transformative potential.