What Happened

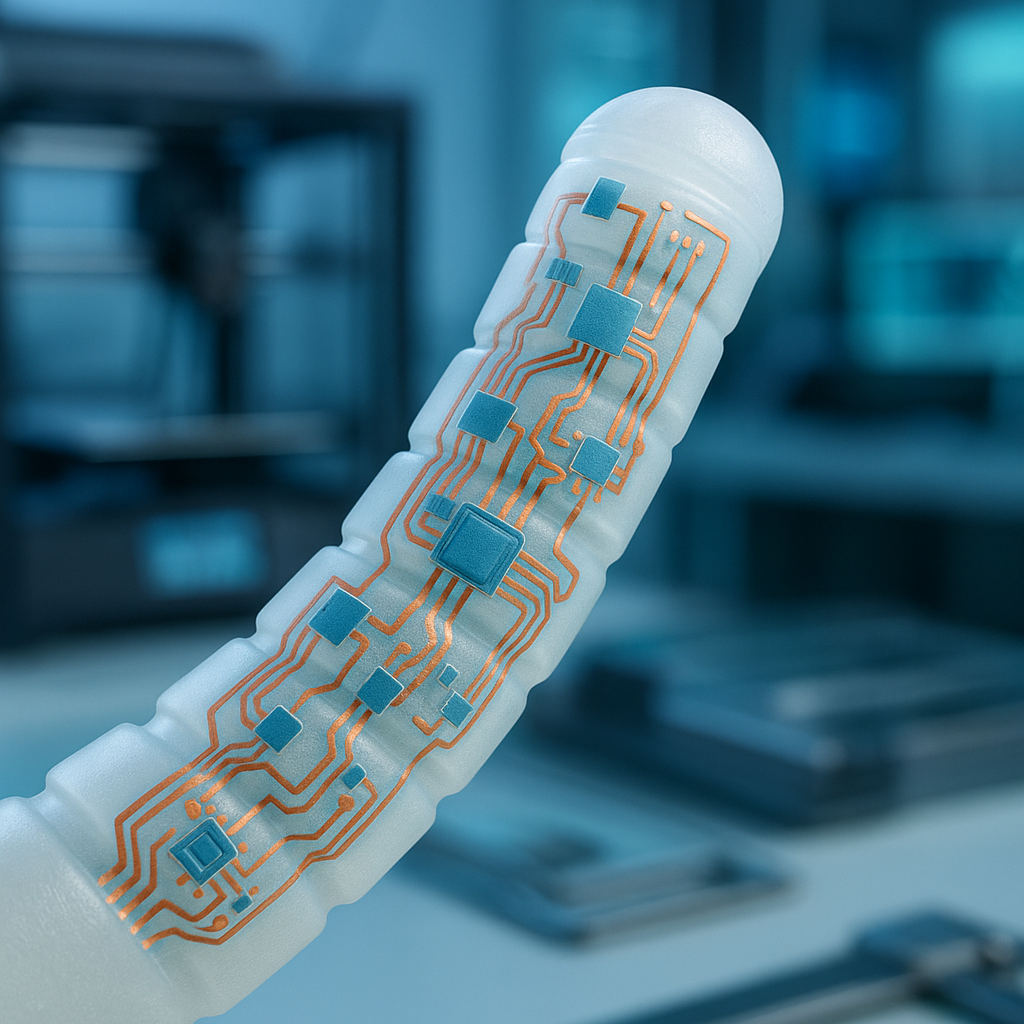

Recent developments in 3D printing technology have enabled the integration of embedded sensors directly within soft robotic components, notably soft robotic fingers. According to a 3DPrint.com article, these advances are pushing the boundaries of soft robotics by embedding sensors during the 3D printing process itself, rather than attaching them post-production.

Why It Matters

The embedding of sensors within soft robotic structures is a significant leap in smart and bio-embedded materials. It allows for the creation of robotic components that can sense their environment and their own mechanical state in real time, improving responsiveness and adaptability. This is particularly important in applications such as prosthetics, wearable robotics, and delicate manipulation tasks where feedback and compliance are crucial. The integration of sensors directly during printing streamlines manufacturing, reduces assembly complexity, and enables more compact and flexible designs.

Technical Context

Traditional robotic fingers and manipulators often rely on rigid components with externally mounted sensors, limiting their flexibility and sensitivity. Soft robotics aims to mimic the compliance and dexterity found in biological systems by using flexible materials. Embedded 3D printing involves depositing sensor materials, such as conductive inks or piezoresistive polymers, layer-by-layer alongside structural elastomers within a single print job. This co-fabrication process creates a seamless interface between the sensor and the soft substrate, enhancing durability and signal fidelity.

Challenges remain in materials compatibility, sensor sensitivity, and the integration of complex sensor networks. The resolution of printing and the durability of embedded sensors under repeated mechanical stress are active research areas. The exact sensor types and materials used in the reported soft robotic fingers were not detailed in the source article, leaving some technical specifics unknown.

Near-Term Prediction Model

Given the current state of embedded sensor 3D printing in soft robotics, the technology is transitioning from R&D to pilot projects within specialized applications. Over the next 12 to 24 months, we expect to see prototypes refined for improved sensor integration and performance, followed by early commercial adoption in niche sectors such as advanced prosthetics and precision soft grippers in manufacturing.

Scaling production and enhancing sensor robustness will be critical to broader market penetration. Collaboration between materials scientists, roboticists, and additive manufacturing experts will accelerate progress. The impact score is moderate to high as this technology promises to redefine human-machine interfaces and soft robotic capabilities, but confidence remains cautious due to technical and manufacturing challenges.

What to Watch

- Advancements in multifunctional printable materials that combine elasticity with sensing capabilities.

- Development of standardized processes for embedding and calibrating sensors during 3D printing.

- Demonstrations of fully integrated soft robotic systems with real-time feedback loops enabled by embedded sensors.

- Commercial announcements from startups or established manufacturers adopting embedded sensor printing in their soft robotic products.

- Research breakthroughs addressing durability and signal stability of embedded sensors under repeated deformation.

In summary, embedding sensors during 3D printing of soft robotic fingers represents a promising frontier in smart and bio-embedded materials, with transformative implications for robotics and wearable technologies. While technical details and scalability challenges remain, the trajectory points toward increasingly sophisticated, responsive, and compact soft robotic systems in the near future.